I built 3 bridges using 1/4"x1/4" and 1/4"x1/2" pine. I ripped a wider 1/4" thick pine into 1/4" and 1/2" using a table saw. I used prototype designs, to 1:48 scale, and they are very strong. I got the designs from a published book on model railway bridges. Pine, plus wood glue with gussets made from old orange crates (which are about 1/16" thick)

I drew the bridges to full O-scale, then cut the wood joints to fit the drawing. when gluing, I used a plastic sheet to keep the glue from sticking to the drawing. This way the drawing acted as a template to ensure the glued pieces stayed the correct shape.

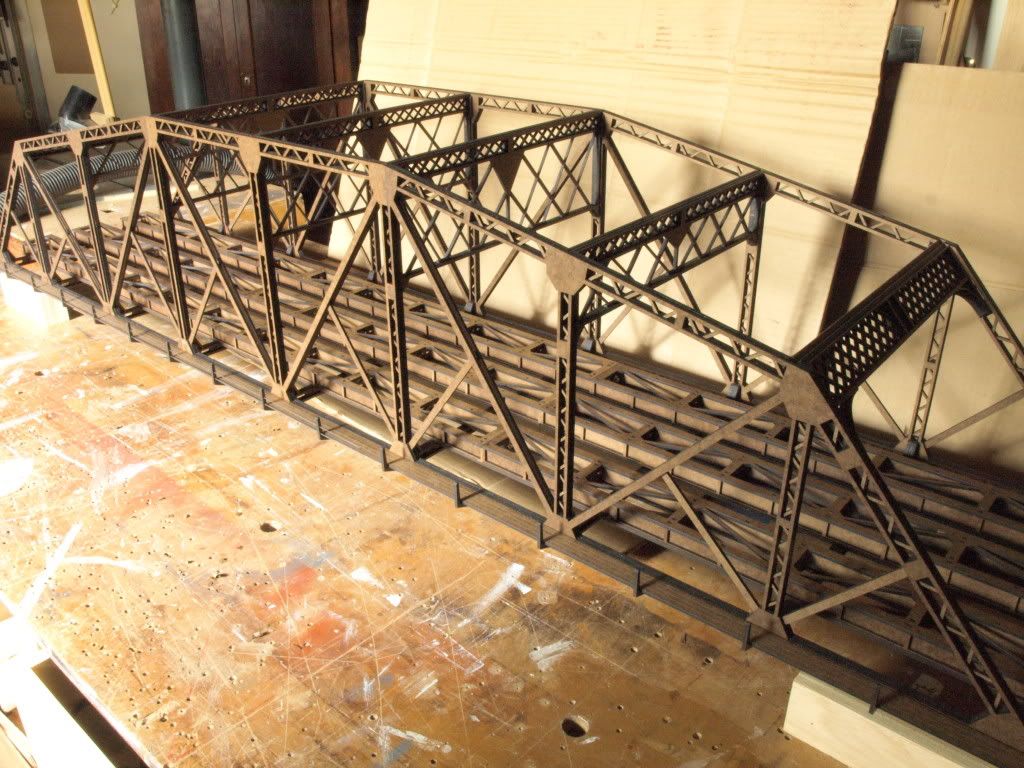

I have included some pictures of the bridges and how I constructed them.

The first bridge is a double track bridge, 40" long. I made a single track version as well.

Coffee stir sticks were used for the smaller bracing. These were used for the lighter cross bracing.

The second bridge is a compressed model of the CP Stoney Creek Bridge. This was a complex bridge, requiring a lot of different part lenghts and angle cuts. I numbered the pieces to keep track of things.

There was lots of cross bracing on this bridge, so the strength was very good.

A third bridge (obove the stoney creek bridge) was a single track bridge, identical to the double track bridge

This was a fun project. it looks more complicated that it really was. I just read some books on railway bridges, chose the designs I liked, drew a template to O-scale size and cut the pieces, one at a time using s fine blade saw, and a mitre box for safety.

I usded wood glue, which is very strong. A few clamps helped hold things together.

Hope this helps: Joe K