Was this item ever made? It was cataloged in 2015.

|

|

Replies sorted oldest to newest

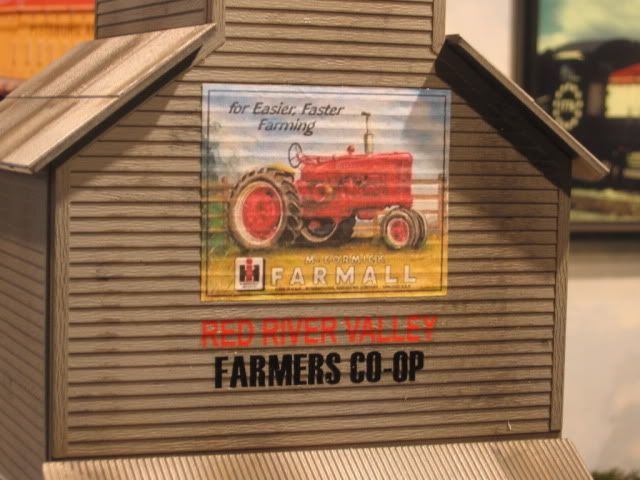

I do not know if this grain elevator was made, but I built an earlier release of this elevator that was available in the 1990's if my memory is correct, from you posted picture they look physically the same but are molded in different colors. You might be able to locate this older kit on the web,believe the cost was around $30.00 in the 1990's. Easy kit to build and weather, adding clear plastic window glazing enhances this kit.

The kit I built was Lionel 6-12726 grain elevator, pale yellow siding and gray corrugated roofing, I saw some on ebay, this is a styrene kit.

If you can not find the kit then you can look up the Plastruct website to find the siding and roofing that matches.

Andrew

I have one. Mine is definitely a kit from the 90's.

It was cancelled ! I pre-ordered it ! This is my thought ! It was cancelled because of the price ! They could not follow through on price because the Chinese could not make it cheap enough ! Cheaper to cancel !

WRGMILW posted:It was cancelled ! I pre-ordered it ! This is my thought ! It was cancelled because of the price ! They could not follow through on price because the Chinese could not make it cheap enough ! Cheaper to cancel !

Once plastic injection molding dies are made plastic parts can be produced for pennies. Then you just snap the parts together to assemble. Perhaps there was not enough demand to justify tooling costs.

They should be available with an internet search. It has been manufactured at least twice since the 1970's (Kit)

Interesting to note that I made a trip to the Red Wing Boot store, Monaca, PA. for my annual work boot replacement. I had to "pre-order" my boots, available some time, after Thanksgiving. Apparently the "made to order", business model exists well beyond the model train industry. I hope they don't cancel my boots, for lack of enough 9D orders. ![]()

![]() Every day the world is just a little bit different. IMO, Mike CT

Every day the world is just a little bit different. IMO, Mike CT ![]() I had an interesting conversation with the store owner, daughter of the original owner, about the Rolodex card files, and buying the same shoe for 35 years. I guess eventually all those names on the rolodex cards go away. Yes, Red Wing Boots, at least some parts of the shoes, and final assembly is still done in Minnesota. with an "Assembled in the USA, stamp on the boots.

I had an interesting conversation with the store owner, daughter of the original owner, about the Rolodex card files, and buying the same shoe for 35 years. I guess eventually all those names on the rolodex cards go away. Yes, Red Wing Boots, at least some parts of the shoes, and final assembly is still done in Minnesota. with an "Assembled in the USA, stamp on the boots.

HI MIKE CT

Great looking Elevator !

Dennis , I agree with you . I refer to the built up model . Maybe Lionel will rerun the kit again .

Mike CT, nice weathering job. You must be studying SIRT, the master's work.

This grain elevator was made as a kit that had to be glued together very carefully.

The assembly of the supported canopy or porch over the tracks is a tricky part to put on in the original kit because it has no alignment pegs and holes. It has to be stuck on approximately, meaning the cement is supporting ALL of the load of the roof.

They might have needed to redesign the wall and roof sections kit to make the final assembly quicker and stronger, but they could not change the injection molds for a reasonable price.

Perhaps the labor costs to slowly put the kit together, without alignment pegs and holes, was the expensive factor.

Andrew

I believe I have an older version still in the box available, just have to dig it out. It's a 1990's model 6-12726. email in my profile.

Here are my finished models and boxes, all have lights.

Just may be what I need to seek out at the OKC Train Show on the 1st and 2nd of December. Already have a "plethora" of Plasticville, adding in some Lionel plastic structures could round it out well. Just put the boxes in with the ones I have. LOL!! need more time to finish the roadbed and ballasting, first. My new job of operating streetcars in OKC is great, but doesn't leave much time for other endeavors. However, the extra income will most definitely come in handy at the train show!!

Jesse TCA 12-68275

Hi Guys, I bought a NIB Lionel Grain Elevator somewhere?? many, many moons ago. Ralston Purina logo. Stock # on box is 6-2796. I've never assembled a model building kit. What level difficulty should I expect to encounter. Thanks, I want to start somewhere.

Tommy

There are only tabs to approximately align the parts, so you have to use cement that will not set too fast or too slow when cementing the parts together.

The lights are solid plastic. You might want to add working lights before cementing the sides together.

The awning or canopy is the most difficult part to assemble because there is nothing solid to hold it in place. A support structure that fastens through slots in the wall would have to be added to make it more durable.

The structure is rather open. They left out the grain bin details. You could add a moving door over the track entrance.

The grain spout could be mounted somewhere under the canopy. Drill a small hole in the wall to put a small tube in place to mount the grain spout.

Andrew

Andrew(FALCONSERVICE) comments can be applied to all building kits, if you compare the box model kit assembly to a kit that has added details such as he recommended or other details such as window glazing, weathering or for advanced modelers kit bashing the finished building mimics a real world structure. Enhancing a box kit requires a sequenced assembly step process, for example, his comment on the solid plastic lights, addition of lite wall mounted goose neck lamps should be installed on the wall before assembling the building, much easier task then applying to the finished building. I use Plastruct Plastic Weld solvent cement on styrene kits, this brush on cement forms the bonded joint by capillary action.

Hi Guys, thanks for your help and your suggestions. I shall now place the boxed unit in a large plastic bin and open. All parts shall be in one bucket. Then I'll read, read direction and plan. I'll work slow and learn. This I shall enjoy.

Tommy

falconservice posted:There are only tabs to approximately align the parts, so you have to use cement that will not set too fast or too slow when cementing the parts together.

The lights are solid plastic. You might want to add working lights before cementing the sides together.

The awning or canopy is the most difficult part to assemble because there is nothing solid to hold it in place. A support structure that fastens through slots in the wall would have to be added to make it more durable.

The structure is rather open. They left out the grain bin details. You could add a moving door over the track entrance.

The grain spout could be mounted somewhere under the canopy. Drill a small hole in the wall to put a small tube in place to mount the grain spout.

Andrew

Hello,

Do you have any pictures of these ideas? Real or model? Thanks!

I built one of these since l am a grain elevator nut, and found one cheap, but have never seen one with a canopy overhanging the tracks, and l have hunted down and explored a lot of them (and built, scratched and bashed, too many of them. That bothers me, especially when l see one on a layout "main line" with through trains blasting through the canopy. I just looked at mine...l left the canopy off, added spouts, and doors, connected a couple of "metal" bins, etc.

Access to this requires an OGR Forum Supporting Membership