Malcolm that is just spectacular, smooth and flowing. What a great job! It may not fit where it was intended but boy I would find a spot for it.

quote:

Originally posted by R.R.:

Would someone explain what keeps those castings at the points from shorting? How are they assembled/insulated?

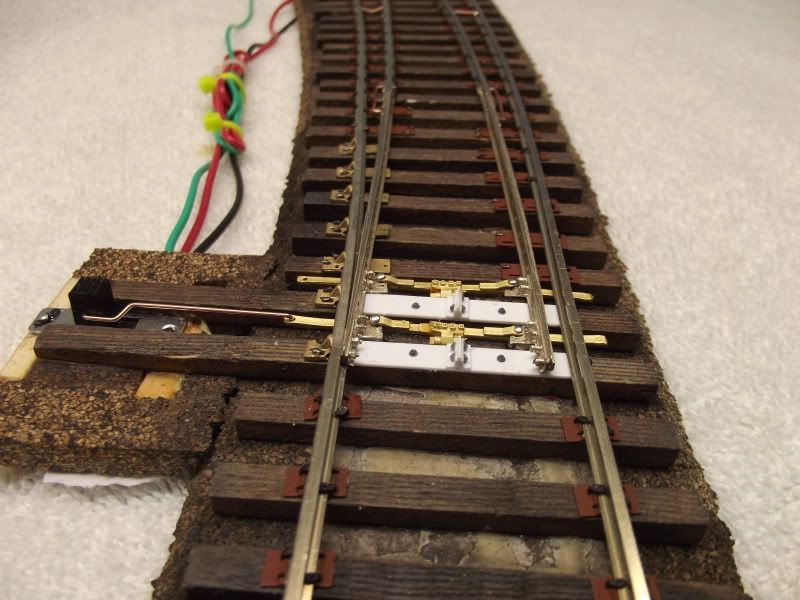

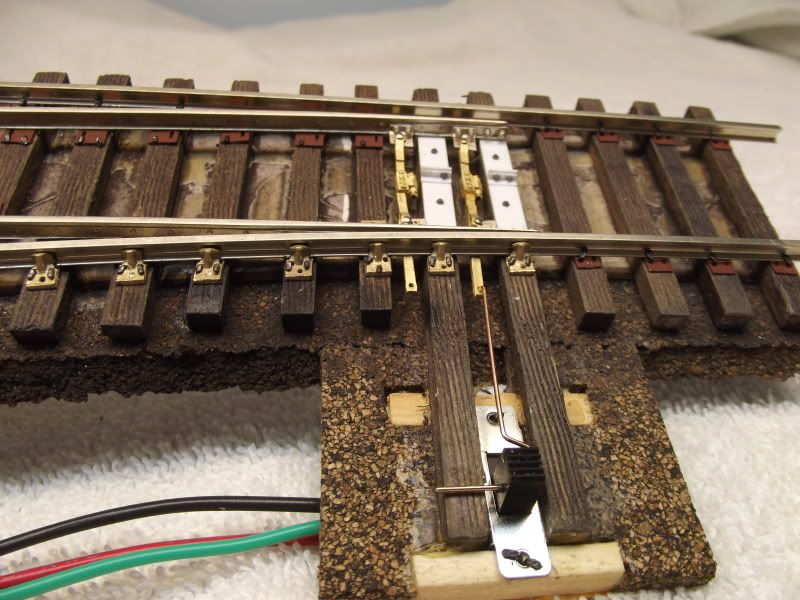

I use paper, fold it over and glue it. The glue and paper insulate the throw bar which is 2 parts. If you look at the right end of this half of the throw bar you will see a pocket where the other part slides in. This part has the female end and you wrap paper around the male end and glue it and insert it into this part. After it has dried just file the excess off or cut it and it is insulated. The gauge plates look like they are styrene so no problems there. On mine I used castings and insulated those the same way I described.