This is related to the GP60 post. I was looking at the GP60 I bought yesterday, I noticed something. The frame and fuel tanks seem like a tank. But the body seemed fragile to me. The make the locomotives to each railroad's configuration, meaning modular construction. Even with that, the body felt "weak" to me. What do you think considering the prices of new Atlas locomotives?

Replies sorted oldest to newest

Fragile add-on pieces are common. Atlas does some decent detail, IMO. The GP 7 handrails easily bend.

It doesn't look like the early model Lionel GP 7/9.

Depends on your perspective - if you're looking at them from the view point of old Lionel stuff where the things like had rails were like 6" scale in diameter and details were grossly over sized, and body was massively over-thick, maybe Atlas appears fragile - if you're looking at them from the view point of brass models, not so much. If you're contemplating using them to play basketball, probably too fragile.

If you want the detail, careful handling is the price you pay.

So much of the new cars have wonderful detail....but all of the detail can break if you're not careful when handling them or taking them out of their boxes.

To me, part of the appeal of the Trainman Line from Atlas is that you still get fairly good detail....but don't have to be quite so gentle when handling.

Notice I keep using the word "handling". ![]()

My personal opinion is,,,,,,yes, the Atlas products are too fragile. The Atlas Master Line freight cars have mostly plastic add-on small parts, which tend to fall off pretty easy. The latest MTH Premier freight cars, however seem to have metal (brass?) add-on small parts which STAY THERE.

I would agree Atlas O products are fragile. However, the Atlas Trainman products offer more detail than MTH, a little less fragile than Atlas O and less expensive. Remember, with any of the manufacturers, quality is not what is used to be.

Interesting take, HW. I'll definitely have to check out some newer MTH pieces.....and have been wanting a new MTH NKP passenger car set.

More recent Lionel freight cars also have brass added on parts that are more sturdy than Atlas. With the Atlas reefers be sure and use the two holes on the back of the styrofoam cradle to coax the car out of its packing. DO NOT grab anything from in front of the cradle except maybe a truck side. Once free of the cradle place on the layout and don't touch again.

turbgine posted:More recent Lionel freight cars also have brass added on parts that are more sturdy than Atlas. With the Atlas reefers be sure and use the two holes on the back of the styrofoam cradle to coax the car out of its packing. DO NOT grab anything from in front of the cradle except maybe a truck side. Once free of the cradle place on the layout and don't touch again.

Good tip!

Berkshire President posted:Interesting take, HW. I'll definitely have to check out some newer MTH pieces.....and have been wanting a new MTH NKP passenger car set.

I was referring to MTH Premier freight cars. I don't have much experience with MTH passenger cars, as they are NOT scale length.

For the price of the locos OUT OF THE BOX, I think the fragile nature of the product is a nonstarter!

Dominic Mazoch posted:For the price of the locos OUT OF THE BOX, I think the fragile nature of the product is a nonstarter!

I guess that is ONE opinion!

Can't tell you how often I find brake wheels or steps lying next to the track broken off my boxcars or hoppers. I replace them or glue them when I can.

turbgine posted:More recent Lionel freight cars also have brass added on parts that are more sturdy than Atlas.......

It's not just the more recent cars, and not just the brass parts. Most of the Lionel scale cars going back to the time they began marketing them have had fairly sturdy detail parts.

Years ago I remember reading about a discussion with Richard Maddox , who was heading up Lionel at the time (you recall he was CEO when Lionel production was moved to China), and he commented that one of the design challenges, that somewhat delayed production of the new scale cars, was coming up with designs for the detail parts, like steps, that would be strong enough and hold up to reasonable use. So this was a significant consideration for Lionel from the beginning.

Atlas Master Line cars are beautiful, but have to be handled with a lot of care. As just a couple of examples, the extended brake wheels on some of the boxcars, reefers and hoppers are almost asking to be broken off, with their thin plastic shafts, and the stirrup steps below the doors on the 40' woodside reefers are notorious - they practically come off if you look at them wrong.

It depends on the type of plastic used to make the parts.

Some of the plastic parts are rigid and brittle, the other plastic parts are more flexible.

Andrew

falconservice posted:It depends on the type of plastic used to make the parts.

Some of the plastic parts are rigid and brittle, the other plastic parts are more flexible.

Andrew

Maybe the importers need to see what is working in HO, where high detail items are common.

What you need to keep in mind is mass. A seven pound atlas locomotive is a whole different beast than its one pound HO counterpart. And more prone to damage due to its inherent mass. The materials in many cases are the same between the HO model and the O scale model. I don't find the atlas O scale engines to be any more fragile than my HO counterparts. Simply that I need to think ahead of time to move them to insure that I am not stressing parts that are more prone to failure. To date I have 5 master locos and zero issues. And I take mine apart and handle them very often. And I super detail them all as well. They are highly detailed scale models. Not toy trains and need to be thought of as such. I also have several master freight cars and zero issues as well

I like to tip an engine and then get it to sit in my hands when carrying it. On steamers, I try and support any articulated drivers too. If you want a better feel when you squeeze the sides, I would recommend adding a simple piece of plastic across the inside of the shells. You can even hot melt it in there.

Each model is different so I don't know about the Atlas GP60 as I don't own one. I have the Atlas GE-8 and to me, it feels good handling it. I have a Erie built and it feels like it's a tank.

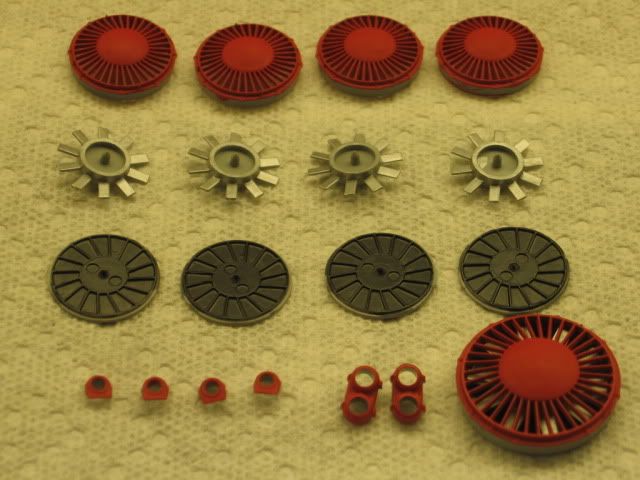

No way! Atlas handrails are crazy thick, borderline ridiculous... Here is my SW1200 after completely redoing grabs and handrails... Much better. I love Atlas, if it wasn't for Atlas I wouldn't be in O.

Attachments

Hello guys and gals

Atlas trains fragile, of course it is with all those fine details put on them, I mean what are you expecting ? My Sunset 3rd S.F. 2-10-4 is all brass but fragile as well (lot of fine details on it too) but the KEY here is "how to handle it the right way" I pick up my brass locomotive from the bottom of the frame easy and gentile. My brass locomotive is very heavy so picking it up is even much harder. I stick with railking trains because it is much easier to handle it even with care. If afraid of breaking a fine detail off the engine or freight car then you're better off buying trains with LESS details so you can enjoy operating the trains without worry (its more fun that way). I just gotten my railking NW-2 switcher last week (after the BCR issues was solved) I REALLY enjoyed this little 4 pound diesel more than my brass S.F. 2-10-4 because it was much easier for me to handle it with out fear of breaking something off. I would say off hand that LESS detail is more. Think about it guys !!!!

Tiffany

Tiffany posted:Hello guys and gals

Atlas trains fragile, of course it is with all those fine details put on them, I mean what are you expecting ? My Sunset 3rd S.F. 2-10-4 is all brass but fragile as well (lot of fine details on it too) but the KEY here is "how to handle it the right way" I pick up my brass locomotive from the bottom of the frame easy and gentile. My brass locomotive is very heavy so picking it up is even much harder. I stick with railking trains because it is much easier to handle it even with care. If afraid of breaking a fine detail off the engine or freight car then you're better off buying trains with LESS details so you can enjoy operating the trains without worry (its more fun that way). I just gotten my railking NW-2 switcher last week (after the BCR issues was solved) I REALLY enjoyed this little 4 pound diesel more than my brass S.F. 2-10-4 because it was much easier for me to handle it with out fear of breaking something off. I would say off hand that LESS detail is more. Think about it guys !!!!

Tiffany

I think she has a point?

I prefer the Yes album - or The Yes Album. Oh, we're not talking about prog rock? Never mind.

David

I dislike fragile. My frames are cutout of quarter inch brass bar, my boilers are 1/16" thick, and my handrails are .032 steel. I do not collect plastic models for reasons other than their strength, but my opinion is this:

If you want dead-accurate models made out of plastic, they will of necessity be fragile. Brass is a little stronger, and in the case of handrails, maybe even capable of being straightened.

I think the choice in the end is realism vs. ruggedness. When I see the handrails on a very nice brass SD-9, I know I am happier with something a bit more substantial. Give me steel, mounted the way the tinplate guys do it.

This is all personal preference, combined with basic strength of materials.

I want the fine detail, not big clunky stuff. If it wasn't for the added detail on scale sized equipment, I wouldn't be in this hobby... or not in this scale anyway. Yes the Atlas Master stuff is fragile, but learn how to handle it carefully. You can't just grab a hold of it with your big mits.

Picked up an Atlas master car when building a 35 car train last week and placed it back in the rack. Why do they have to be 2 to 3 times heavier than everyone else?

Boat anchors!

bob2 posted:If you want dead-accurate models made out of plastic, they will of necessity be fragile.

I don't know that such a generalization is in fact accurate. The type of plastic is probably key and the history being plastic ='s styrene may be the origin of this sort of dogma.

If it could be made of Delrin or ABS or some other "engineering" plastic, fragile might not be a real variable anymore.

Then again, there will always be some fumbily-fingered ham-handed gimboid that will expect a plastic model to be just as solid as cast iron and after breaking a bit off will trumpet from some podium how fragile his model is.......

Aha - a controversy! I maintain that, no matter what material you use, the closer to scale you get, the more fragile the model. A brass boxcar, with sides scaled down by 1:48, would probably collapse the first time it was picked up. A full scale Bettendorf truck, properly cored, even in brass, would not be particularly strong. And they tell me that my minimum .032 dia. handrails are twice what they should be. No way will I go skinnier than that, even in steel.

bob2 posted:Aha - a controversy! I maintain that, no matter what material you use, the closer to scale you get, the more fragile the model. A brass boxcar, with sides scaled down by 1:48, would probably collapse the first time it was picked up. A full scale Bettendorf truck, properly cored, even in brass, would not be particularly strong. And they tell me that my minimum .032 dia. handrails are twice what they should be. No way will I go skinnier than that, even in steel.

Not really. I merely point out self-imposed limits of thinking - plastic ='s fragile but that's in part to the nature of the type of plastic. Your points regarding brass may also be true; why limit your thinking to brass? Out of all of the materials that are available in this world today, why do model RR'ers, O scale in particular, limit their thinking to just a tiny fraction of the available possibilities.......

I really appreciate what you guys are saying. However,I am more worried about zinc pest and crumbling parts.

Norm

AtlasO engine and freight car detail components are less suspect to damage/breakage than O scale car kits especially sill steps and grab irons. It seams to me that AtlasO in the past and still continues to balance their product designs and durability for the market demand for products between the 3-Rail and O Scale modelers. As an example, the 50 foot gondola car, scale size and highly detailed,but grab irons molded to carbody and sill steps more stout than comparable Intermountain or Red Caboose O Scale kit sill steps.

Norm posted:I really appreciate what you guys are saying. However,I am more worried about zinc pest and crumbling parts.

Norm

I very much agree with you about zinc pest, but that problem is not limited to Atlas, it has been a problem with all train manufacturers since the early beginnings of model trains, in all scales and gauges. Regarding model fragility, I think that may be one reason I refer MTH Premier freight cars. They have an acceptable level of detail, yet seem pretty robust so they can stand up to being handled. This is most important if you run on a modular layout, because transporting models to and from setups is very hard on fragile, fine details.

Bill in FL

Mike CT posted:

It doesn't look like the early model Lionel GP 7/9.

Maybe what you should be thinking is, the early model Lionel GP 7/9, doesn't look much like the REAL engine.

When hand rails get scaled down to 1/48, they tend to get flimsy.

Simon

Bill Nielsen posted:Norm posted:I really appreciate what you guys are saying. However,I am more worried about zinc pest and crumbling parts.

Norm

I very much agree with you about zinc pest, but that problem is not limited to Atlas, it has been a problem with all train manufacturers since the early beginnings of model trains, in all scales and gauges. Regarding model fragility, I think that may be one reason I refer MTH Premier freight cars. They have an acceptable level of detail, yet seem pretty robust so they can stand up to being handled. This is most important if you run on a modular layout, because transporting models to and from setups is very hard on fragile, fine details.

Bill in FL

Hello Norm and Bill Nielsen

I agree with you both about the zinc pest problem but last week I purchased NOS (new Old Stock) Railking NW-2 diesel switcher #30-2157-1 as this one is made in 1999 so its 17 years old. This model has 1/8 inch thick die-cast frame, trucks, pilots, truck side frames and couplers, fuel tank and this one PASSED test of time for zinc pest problem, found NONE !!! I guess I got lucky this time. I think as per label on the box says "made in Korea" perhaps Koreans have better quality control in making zinc castings ?

Tiffany

Tiffany posted:Bill Nielsen posted:Norm posted:I really appreciate what you guys are saying. However,I am more worried about zinc pest and crumbling parts.

Norm

I very much agree with you about zinc pest, but that problem is not limited to Atlas, it has been a problem with all train manufacturers since the early beginnings of model trains, in all scales and gauges. Regarding model fragility, I think that may be one reason I refer MTH Premier freight cars. They have an acceptable level of detail, yet seem pretty robust so they can stand up to being handled. This is most important if you run on a modular layout, because transporting models to and from setups is very hard on fragile, fine details.

Bill in FL

Hello Norm and Bill Nielsen

I agree with you both about the zinc pest problem but last week I purchased NOS (new Old Stock) Railking NW-2 diesel switcher #30-2157-1 as this one is made in 1999 so its 17 years old. This model has 1/8 inch thick die-cast frame, trucks, pilots, truck side frames and couplers, fuel tank and this one PASSED test of time for zinc pest problem, found NONE !!! I guess I got lucky this time. I think as per label on the box says "made in Korea" perhaps Koreans have better quality control in making zinc castings ?

Tiffany

Hard to say, since zinc pest shows up in products made in every country, including (but not limited to) the USA, Germany, Italy, England, Japan, Korea, China, and others. As long a time as they've been making items from zinc, one would expect by now that they would have figured out how to get it right. Apparently not...

My personal feeling is that there is no acceptable excuse for metal failure, whatever the age of the item.

Bill in FtL

Let's face it...if you cannot even remove a car from its packaging without breaking off the mid car steps (box and refers) or the end steps, it is TOO fragile. If you cannot run it on your layout without a truck side frame breaking due to zinc rot, or a coupler breaks and you run into your own caboose, IT IS OF INFERIOR QUALITY! IF you cannot run a train at 18V because you fail snap relays, it is junk. This has been my experience with one manufacturer's products.

Bill Nielsen posted:Tiffany posted:Bill Nielsen posted:Norm posted:I really appreciate what you guys are saying. However,I am more worried about zinc pest and crumbling parts.

Norm

I very much agree with you about zinc pest, but that problem is not limited to Atlas, it has been a problem with all train manufacturers since the early beginnings of model trains, in all scales and gauges. Regarding model fragility, I think that may be one reason I refer MTH Premier freight cars. They have an acceptable level of detail, yet seem pretty robust so they can stand up to being handled. This is most important if you run on a modular layout, because transporting models to and from setups is very hard on fragile, fine details.

Bill in FL

Hello Norm and Bill Nielsen

I agree with you both about the zinc pest problem but last week I purchased NOS (new Old Stock) Railking NW-2 diesel switcher #30-2157-1 as this one is made in 1999 so its 17 years old. This model has 1/8 inch thick die-cast frame, trucks, pilots, truck side frames and couplers, fuel tank and this one PASSED test of time for zinc pest problem, found NONE !!! I guess I got lucky this time. I think as per label on the box says "made in Korea" perhaps Koreans have better quality control in making zinc castings ?

Tiffany

Hard to say, since zinc pest shows up in products made in every country, including (but not limited to) the USA, Germany, Italy, England, Japan, Korea, China, and others. As long a time as they've been making items from zinc, one would expect by now that they would have figured out how to get it right. Apparently not...

My personal feeling is that there is no acceptable excuse for metal failure, whatever the age of the item.

Bill in FtL

Hello Bill in FtL

I AGREED with you all the way with this "no acceptable excuse for metal failure" ![]()

Tiffany

Hudson5432 posted:Let's face it...if you cannot even remove a car from its packaging without breaking off the mid car steps (box and refers) or the end steps, it is TOO fragile. If you cannot run it on your layout without a truck side frame breaking due to zinc rot, or a coupler breaks and you run into your own caboose, IT IS OF INFERIOR QUALITY! IF you cannot run a train at 18V because you fail snap relays, it is junk. This has been my experience with one manufacturer's products.

Hello Hudson5432

Then the ONLY thing left to do is to LEAVE in the box and NEVER take it out !!!

Tiffany

To avoid a shark attack, stay out of the water.

To avoid metal rot, stay away from zinc!

You would think the train makers have figured this out!