Thanks guys, I will skip the soldering.

The main reason I want to bend the track is I already own it. I will try to bend a few pieces and see if i can get a good enough bend myself.

Before you start, I'd suggest you detail how you plan to bend the track; i.e. what's your process?

What tools will you use? What screws will you use to secure the track? What will you use to cut the uneven ends of the track once bent? And so on.....

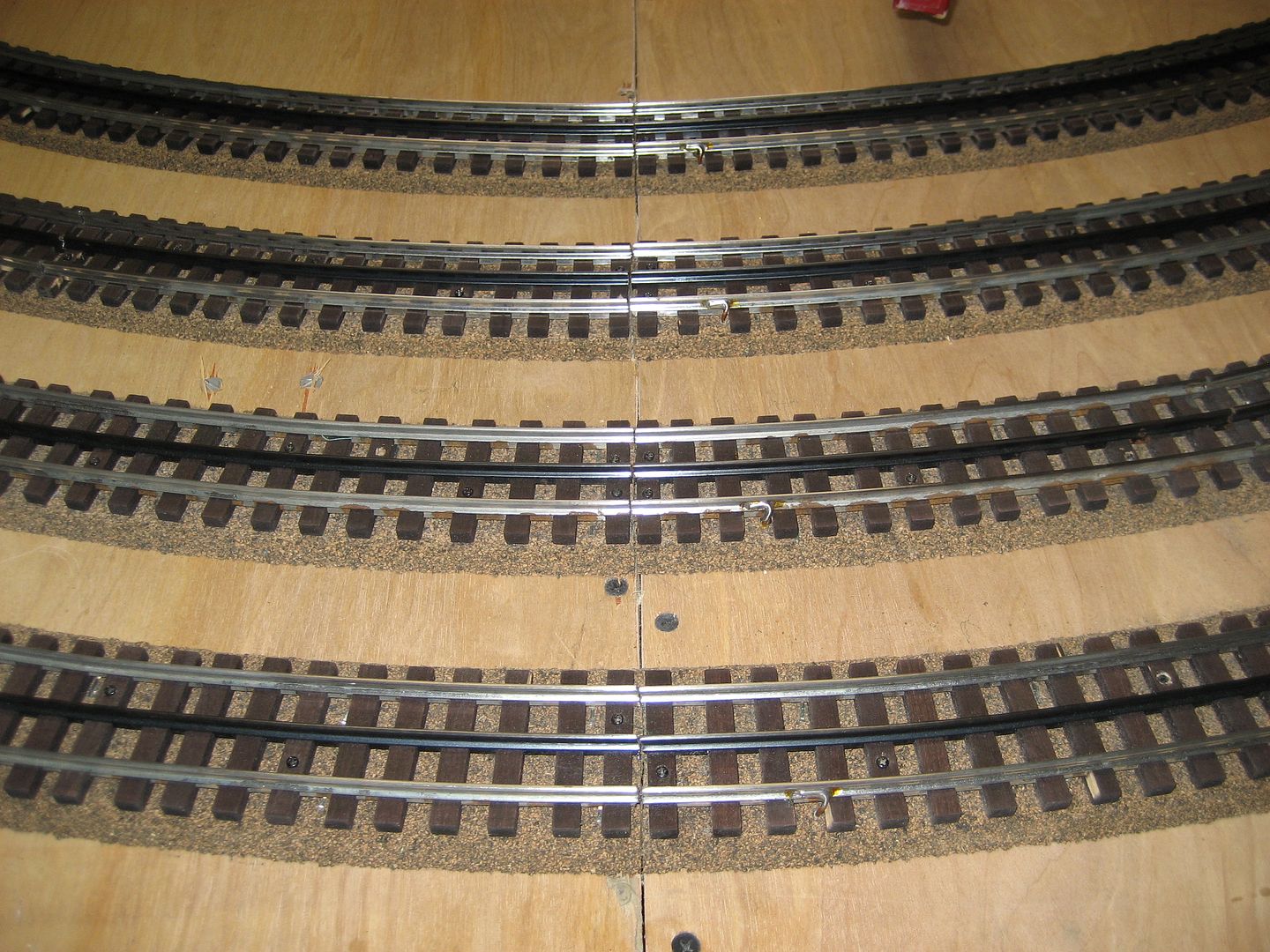

Also, how much curved track do you need? I ask because I've had good luck buying, at very good prices, small diameter curved Ross and Gargraves track by posting in the WTB forum here at OGR; and, did just that a couple of years ago for a small Christmas layout. Frankly, having bent my fair share of Gargraves track on a modest sized around the room layout years ago, and still having all of the tools required to do so for a small Christmas layout, buying used sectional track was a FANTASTIC decision if I do say so myself.

Question: If I bought sectional track does that mean I'm disqualified from "doing all of the work on my layout?"