Been looking for a while now for a 2-8-0 Consolidation. It would fit nicely on my shelf railroad. I just don't see any available in 2-rail.

Are they out there? Who made them?

|

|

Been looking for a while now for a 2-8-0 Consolidation. It would fit nicely on my shelf railroad. I just don't see any available in 2-rail.

Are they out there? Who made them?

Replies sorted oldest to newest

Weaver made a generic 2-8-0 in many different road names. I picked one up in B&M.

Forum sponsor Trainz has a PRR 2-8-0 for sale right now,…..

Pat

Pretty sure SP C-9s and C-10s were made in O scale. Likely UP Harriman equivalents. brasstrains.com shows a few O scale 2-8-0s.

Pete

@HudsonORailRoader posted:Been looking for a while now for a 2-8-0 Consolidation. It would fit nicely on my shelf railroad. I just don't see any available in 2-rail.

Are they out there? Who made them?

CLW, Key, Westside, Sunset, and quite a few others.....popular wheel arrangement.

Lots. Weaver did a diecast generic one. It is geared more for 3 rail speeds, so probably runs better with DCC. Weaver also imported a brass PRR H10, a large 2-8-0. I have one, a very good runner. Central Locomotive Works (CLW) kit is of the same locomotive. The kit is more than screwdriver, but not super craftsman.

Sunset over the years has imported quite a few. They did an PRR H8/H9 back in the 80s. They did a small PRR H6sb in the 90s. The H6 is a very nice runner and a model of the latest version of the prototype. I have one of these too. Sunset also did a B&O 2-8-0 that is very similar to the H6. These were built when PRR controlled B&O. Sunset did another 2-8-0 that was presented as a Santa Fe.

Overland models did a very very nice model of a Western Maryland large 2-8-0. I have seen these run and they seem very nice.

US Hobbies imported a nice looking UP 2-8-0 many years ago. It is probably a good runner. I don't have one, but I have other USH locos and they are all great.

There are probably others that I don't know about.

You might also want to consider an 0-6-0 or 0-8-0 US Hobbies imported a USRA 0-8-0 that is sturdy and good runner. Sunset imported a USRA 0-6-0 in a couple of versions. I have also seen a Max Grey USRA 0-6-0 built by Toby. I nothing about this one. Weaver also imported a USRA 0-6-0.

Sunset made one in Santa Fe in 2-rail. Nicely done piece, by the way. I picked up one with DCC/sound a couple of years ago. Haven't run it yet because I haven't built out a layout since I was retiring/moving. I'm thinking about building a switching deck just for this locomotive and a 2-rail Sunset 44-tonner I picked up a bit earlier.

If you want PRR, Key is probably the best. CLW is as good as the guy that built it.

ECI

Glacier Park Models did an Espee C-8 in the early 2000's.

@PRRMP54 posted:

I have a Section 1 and 2 set of this that I was going to use with a different boiler and tender, but I am missing the side rods.

Iron Horse Models/Precision Scale Ma & Pa 2-8-0.

Even Ed Reutling (Adirondack Car & Foundry) did one in resin.

MTH made its die-cast Premier model of Long Island Rail Road H-10s 2-8-0 #111 (20-3230-2) with scale wheels. It was listed as "Proto-Scale 3-2 3-Rail/2-Rail Conversion Capable." It is a model of a Pennsylvania Railroad H-10s that ran on Long Island. The LIRR was a PRR subsidiary between 1900 and 1966 and used several types of PRR steam locomotives.

MELGAR

The MTH H-10 is a very nice model. This is the PS-2 (2 rail) version:

As Melgar says, it was available in 2 rail. I straightend the tether, added a deckplate, and shortened the drawbar:

Pennsy fanatics could complain about the smoke box hinges being obtrusive and the pilot wheels a tad too far forward. And maybe the cab window frames being a bit thick. But I wouldn't.

The PS3 version issued later had a wireless drawbar and a deckplate. But the smokebox hinges are still obtrusive. And if I recall the drawbar was too long. I bought one and returned it because it kept the large hinges, and I had already modified mine for a short drawbar and deckplate.

For what its worth, I sold off all my steam except the H-10. With its stubby brawny look and puffing smoke its a crowd pleaser. Especially for the crowd under age 10.

@MELGAR posted:MTH made its die-cast Premier model of Long Island Rail Road H-10s 2-8-0 #111 (20-3230-2) with scale wheels. It was listed as "Proto-Scale 3-2 3-Rail/2-Rail Conversion Capable." It is a model of a Pennsylvania Railroad H-10s that ran on Long Island. The LIRR was a PRR subsidiary between 1900 and 1966 and used several types of PRR steam locomotives.

MELGAR

Here is an MTH engineering sample (unpainted one on the right) that I got on ebay and eventually traded to a friend for the CLW one in the above photos (note all of the brass detail parts):

@PRRMP54 posted:

@HudsonORailRoader posted:I have the MTH H-10 in 3-rail. I understand it can be converted to 2-rail. How is that done?

I honestly do not know. On the engineering sample one of the driver tires was loose/not attached (that may have been on purpose) but I do do not remember now if there was any insulation present.

@John Sethian posted:For what its worth, I sold off all my steam except the H-10.

Shocking! ![]()

With its stubby brawny look and puffing smoke its a crowd pleaser. Especially for the crowd under age 10.

![]()

@John Sethian posted:@HudsonORailRoader posted:I have the MTH H-10 in 3-rail. I understand it can be converted to 2-rail. How is that done?First you need to have a PRR H-10 labelled as "Proto-Scale 3-2, 3-Rail/2-Rail Conversion Capable." The very earliest H-10s were not, the subsquent runs with PS 2 and PS 3 wereSecond, if you are going to run on 2 rail track, the H-10 will run much better if it has "Scale Wheels". The product number ends with "-2". For example 20-3230-2.To convert from three rail to 2 rail, simple pull the pick up rollers off and flip the switch on the tender that says 2 rail/3 RailIf you have a Hi-Rail version (Product number ends in -1) You can still convert to 2 rail operation using the same procedure, but it will probably have problems running through 2 rail switches, as the wheel flanges are two wide to go between the running rail and guard rail

Sounds like a job for @harmonyards; he’s turned down my drivers and does wonders with pilot wheels.

Here is a thought on MTH steamers for use in 2 rail. Years ago, I reviewed an MTH 2-10-4 in 2 rail for a magazine. It had solid side rods, the rods connecting the drivers to each other. (The main rod is one from the cylinders to the drivers). It had all flanged wheels. It ran fine and was a pretty nice model. In some respects it was nice than the Max Grey version I owned. However, it would not go around my 52 inch radius curves (0104). I laid some temporary track and found it requred 68 inch radius (0136). My Max Grey brass version had jointed side rods and would go around the 52 inch radius.

I have noticed that all the steamers I have seen made first for 3 rail have solid side rods and blind drivers except at the ends. The side rods are long stampings with the representation for the joints etched in. All the brass steamers I have seen have jointed side rods whether or not they have blind drivers.

solid side rods do NOT allow the drivers to move sideways any for a curve, no matter how much sideplay they have. They force the rear drivers to go opposite to front ones because they form a rigid parallelogram with the drivers. Real steamers have the jointed side rods.

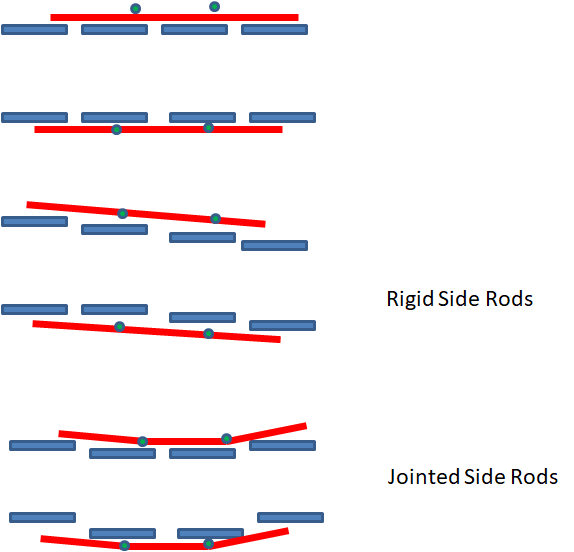

The diagram below illustrates this: The blue blocks represent the drivers, the red bars the side rods and the green dots representing joints. The top one is the loco on a straight. The second one is what happens going into a curve with rigid (solid) side rods, and the bottom one is what happens going into a curve with jointed side rods.

My personal choice is to stay away from MTH steamers for 2 rail because this requires much larger curve radius, and we already use larger radii.

By the way, weaver diecast steamers also came with rigid side rods. I had an O-8-0 that would not go around 48 inch radius (096) while my brass one had no problems.

PRR Jim

The MTH 2-10-4 was notorious for having all drivers flanged and a long wheelbase, which as you pointed out severely compromised their ability to negotate anything less than 68" radius curves. Later MTH steamers, even with ten drivers, had the center drivers blind and they could go around much tighter curves. I have two MTH Decapods (2-10-0), a Consolidation (2-8-0), and a Mikado (2-8-2). All had no problems with 44" radius curves.

Incidentally, the prototype Decapod had blinded center drivers as well!

@prrjim posted:The diagram below illustrates this: The blue blocks represent the drivers, the red bars the side rods and the green dots representing joints. The top one is the loco on a straight. The second one is what happens going into a curve with rigid (solid) side rods, and the bottom one is what happens going into a curve with jointed side rods.

My personal choice is to stay away from MTH steamers for 2 rail because this requires much larger curve radius, and we already use larger radii.

By the way, weaver diecast steamers also came with rigid side rods. I had an O-8-0 that would not go around 48 inch radius (096) while my brass one had no problems.

Excellent analysis. Thanks for the explanation. This was really helpful. I may keep the MTH on the 3-rail layout and just find a 2-rail 2-8-0 somewhere.

2-8-0 available for preorder now from Atlas.

@John Sethian posted:PRR Jim

The MTH 2-10-4 was notorious for having all drivers flanged and a long wheelbase, which as you pointed out severely compromised their ability to negotate anything less than 68" radius curves. Later MTH steamers, even with ten drivers, had the center drivers blind and they could go around much tighter curves. I have two MTH Decapods (2-10-0), a Consolidation (2-8-0), and a Mikado (2-8-2). All had no problems with 44" radius curves.

Incidentally, the prototype Decapod had blinded center drivers as well!

I made mine ( Texas type that is) have blind drivers! ![]()

I run a lot of MTH steam on my 2 rail layout. Trackwork is decent. Any problem shows up in all the brands I run.

Re: new Atlas model is apparently based on Weaver model and 2rail is advertised as working on 36” radius.

@prrjim posted:solid side rods do NOT allow the drivers to move sideways any for a curve, no matter how much sideplay they have. They force the rear drivers to go opposite to front ones because they form a rigid parallelogram with the drivers. Real steamers have the jointed side rods.

My personal choice is to stay away from MTH steamers for 2 rail because this requires much larger curve radius, and we already use larger radii.

Someone give that man a cigar! Well said, Jim.

My CLW H10 less the tender which I am on the hunt for. Lines West high side tenders are fairly common on 3 rail versions, but I am looking for a low side tender in 2 rail or one to convert to 2 rail.

As others have said there have been a number of 2-8-0 models made over the years in 2 rail. It is a very popular wheel arrangement.

Here is a photo of a Weaver 2-8-0 for sale on a table at the most recent Strasburg Show. I don't remember Who's table it was but I don't think it sold at the show.

Pacific Fast Mail also made one.

The Western Maryland H9 is another option. I think it was the largest prototype consolidation. Overland (brass) and MTH (diecast) have made them. Found on Youtube...

It took a while but I recently scored an undecorated 2 rail one and I was pumped. Just make sure the tender electrical connector is plugged in all the way or it won't run, ask me how I know lol ![]()

Vince

@prrjim posted:Here is a thought on MTH steamers for use in 2 rail. Years ago, I reviewed an MTH 2-10-4 in 2 rail for a magazine. It had solid side rods, the rods connecting the drivers to each other. (The main rod is one from the cylinders to the drivers). It had all flanged wheels. It ran fine and was a pretty nice model. In some respects it was nice than the Max Grey version I owned. However, it would not go around my 52 inch radius curves (0104). I laid some temporary track and found it requred 68 inch radius (0136). My Max Grey brass version had jointed side rods and would go around the 52 inch radius.

I have noticed that all the steamers I have seen made first for 3 rail have solid side rods and blind drivers except at the ends. The side rods are long stampings with the representation for the joints etched in. All the brass steamers I have seen have jointed side rods whether or not they have blind drivers.

solid side rods do NOT allow the drivers to move sideways any for a curve, no matter how much sideplay they have. They force the rear drivers to go opposite to front ones because they form a rigid parallelogram with the drivers. Real steamers have the jointed side rods.

The diagram below illustrates this: The blue blocks represent the drivers, the red bars the side rods and the green dots representing joints. The top one is the loco on a straight. The second one is what happens going into a curve with rigid (solid) side rods, and the bottom one is what happens going into a curve with jointed side rods.

My personal choice is to stay away from MTH steamers for 2 rail because this requires much larger curve radius, and we already use larger radii.

By the way, weaver diecast steamers also came with rigid side rods. I had an O-8-0 that would not go around 48 inch radius (096) while my brass one had no problems.

I have heard this theory many times and I always accepted it as truth because it just makes sense. I certainly can't disagree with the theory. However, lately I have been thinking about it and I am saying to myself if this theory is true than why do all of my MTH steam locomotives go through fairly tight curves (some as low as 36"R). I have a MTH Railking 0-8-0 which was professionally converted to 2 rail. It has flanges on all the drivers. When I first got it back from the guy who did the conversion there was pretty much no side to side play and this engine would not go around my largest curve (at the time that was 54"R) and I feared it would need a much larger curve than that. So I told the guy who did the conversion and he said send it back to him. I don't know what he did but when I got it back it had a lot of side to side play like it did before and was now able to handle 36"R curves. But why was it able to handle such curves since it does have the rigid side rods? Shouldn't they be holding it back to a much larger radius? So I decided to do some research. I checked the side to side play on my locomotive with my dial indicator. The rear most wheels it has 0.053" of side to side play; the next wheels forward (the driving wheels) only 0.003"; the next wheels after that 0.039" and foremost wheels 0.046". I put the locomotive upside and put a piece of Atlas 36"R track on it. I noticed that the side rods, although they are rigid, there is additional play at the point where they connect to the main driving wheels (the wheels connected to the electric motor). This allows the rear wheels to go inward on one side going to a curve and the the four wheels in front of the driving wheels to go outward in curve and of course the opposite on the other side of the engine.

"solid side rods do NOT allow the drivers to move sideways any for a curve, no matter how much sideplay they have." In my opinion it is a combination of both: the side to side play of the drivers and the play where the rigid side rods connect to the driving wheels that allows the engine to go around reasonably tight curves. I do not disagree in entirety with prrjim's theory above. In my opinion if a user were to get into really tight curves like say 16.5"R (O31) or even a little larger then yes due to the rigid side rods and having all the drivers with flanges the user would run into the exact issue Jim is talking about. When it comes to reasonably tight curves like a 36"R or 40"R I don't think tons of side to side play are going to be needed. As you can see the measurements on my locomotive. Again this isn't a factory MTH engine but since my other MTH engines run on reasonably tight curves like this I would assume they have similar tolerances. This is not to say that rigid side rods are better than jointed side rods. Of course jointed side rods are a million times better but one can also have fun with a steam locomotive that has rigid side rods.

Access to this requires an OGR Forum Supporting Membership