which turnout brand do you have and if thats the case how did you modify it for spring function?

I'm thinking of a handfree loop which is what this topic was for

|

|

which turnout brand do you have and if thats the case how did you modify it for spring function?

I'm thinking of a handfree loop which is what this topic was for

Replies sorted oldest to newest

I have seen this done before with a small coil spring kinda like out of a ball point pen. All my turnouts are spring loaded because I use Tortise switch machines.They work great.

Clem k

I made a pair of modified Gar Graves manual switches for return loops. I cut a roughly 1 1/2 inch long piece of quarter inch brass tubing and then soldered a piece of flat brass on one end to close it off. I then glued the tubing between the long ties that normally hold the Caboose Hobbies manual switch control with the open end facing the switch.

Inside the tubing I placed a spring and then bent one end so it fit into the hole in the throw bar of the switch. The tension on the throw bar keeps the switch in one position. The tension on the spring is low enough that the train easy passes the opposite way. You can mount the spring mechanism on either side of the switch depending on which way you want the switch to be normally "set"

FasTrack manual switches work perfectly, very reliably, right out of the box w/o modifications. The advantage with the FasTrack switches is that the route alternates for variety.

If your operations dictate, I imagine the FasTrack switches can be easily set up(non-destructively) for one-way hairspring operation.

thanks for the replies, I never thought of that but ballpen springs makes sense. I'll have to see which track bands I decide upon and then see what kind of manual switch machine it may come with ![]()

Tom Groff has a number of spring loaded turnouts on his Choo-Choo Barn layout at Strasburg. An aluminum streamliner and a Reading freight run in opposite directions on an outer loop. The streamliner stops at a station and starts the freight. The freight runs past the streamliner at the station and stops by a mountain at the upper left. That starts the streamliner and the cycle repeats. Turnouts are easily observed.

On another loop around that mountain, an "0-27" streamliner and a railbus run in opposite directions. Relays trigger back-and-forth movements of the railbus in a tight space, like a compressed (and level) switchback. It's amazing to watch.

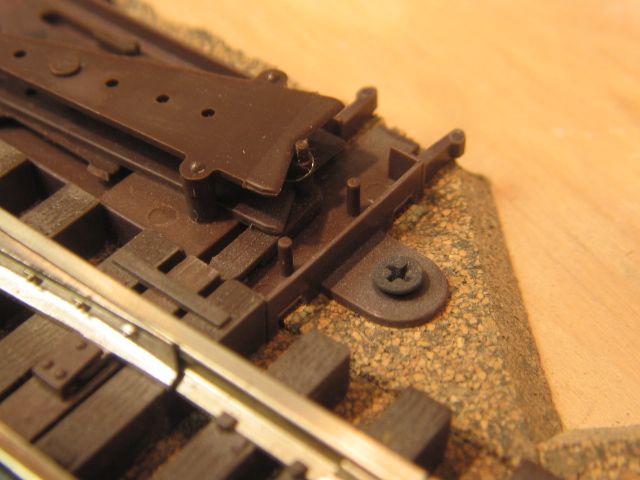

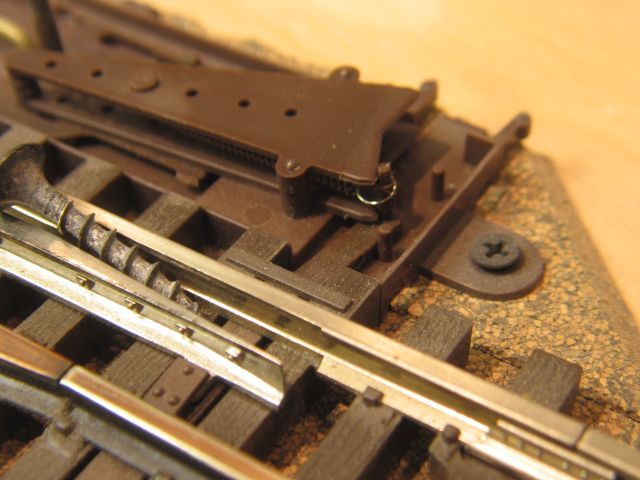

The local club has a subway loop with a hidden siding. Two subway trains run in opposite directions on the loop. There is a spring switch at each end of the siding. The spring is made from a small size section of music wire. One end hooks into the throw bar on the switch. The other end is bent down and pushed into a hole in the ties. It's held in position by use of HO track spikes. It's easy to adjust the tension on the points just by moving two of the spikes. Works well.

We sprung a couple of them on the club layout using ball-point pen springs mounted parallel to the rails. They're stiff enough to keep the points in place, but provide minimal resistance when a train runs through against the points. On one of them, I've been inclined to use an Azatrax two-channel turnout control board and infrared sensors to throw a Tortoise motor similar to what I did with the staging yard exit.

Atlas switches/switch machines are spring loaded, the mechanism is in the switch motor. Both Atlas and Ross switches, I found electric automatic non-de-rail a better solution to entering a switch thrown the wrong way.

Access to this requires an OGR Forum Supporting Membership