Toying with the idea of building a small layout, simple, roughly 4x8ish... I have a bunch of lightly used gargraves (I think) flex I picked up years ago... I've seen the video on gargraves site on bending the track, and was wondering... can I effectively bend this down to O-3X curves?

Replies sorted oldest to newest

No problem. I made an 016 circle once for a trolly line.

Pete

Wow, O16! Now that's tight! I should have no trouble getting to O36ish then... yay!

Thanks!

Gargraves actually makes 031 pre formed curves. Same track with reinforcing ribs to hold it in shape.

Pete

Technically, GarGraves makes O32 sectional curves. ![]() However, I once asked them how tight I could bend their flex track because I wanted something larger than O31/O32, but couldn't fit O42 at the time. I was told that all their sectional curves begin as flex track and are manually bent using the techniques in their video. If you look at photos of their sectional track vs their flex track though, you'll see that what Pete calls "ribs" are added to the sectional curves at some point in the manufacturing process. As I understand it, when bending tight curves, the key is to bend them a little tighter than you need in order to reduce the pressure to bend back. You'll probably need to fasten the track in more places too for the same reason. Mike CT is the resident expert on bending GarGraves, but I don't believe he bends it that tight. Let us know how it works.

However, I once asked them how tight I could bend their flex track because I wanted something larger than O31/O32, but couldn't fit O42 at the time. I was told that all their sectional curves begin as flex track and are manually bent using the techniques in their video. If you look at photos of their sectional track vs their flex track though, you'll see that what Pete calls "ribs" are added to the sectional curves at some point in the manufacturing process. As I understand it, when bending tight curves, the key is to bend them a little tighter than you need in order to reduce the pressure to bend back. You'll probably need to fasten the track in more places too for the same reason. Mike CT is the resident expert on bending GarGraves, but I don't believe he bends it that tight. Let us know how it works.

Relatively large curves. (Edit/ADD, 1/21/21: O-90, relatively easy, less than O-90 more difficult). I used a large compass to do the curves. I screwed the track every 4" to 5" with the tip of the ball point pen on the center rail.

Takes some time, obviously the inside rail will be shorter than the other two. The wooden ties need to be re-positioned as you work the bend.

Curve center.

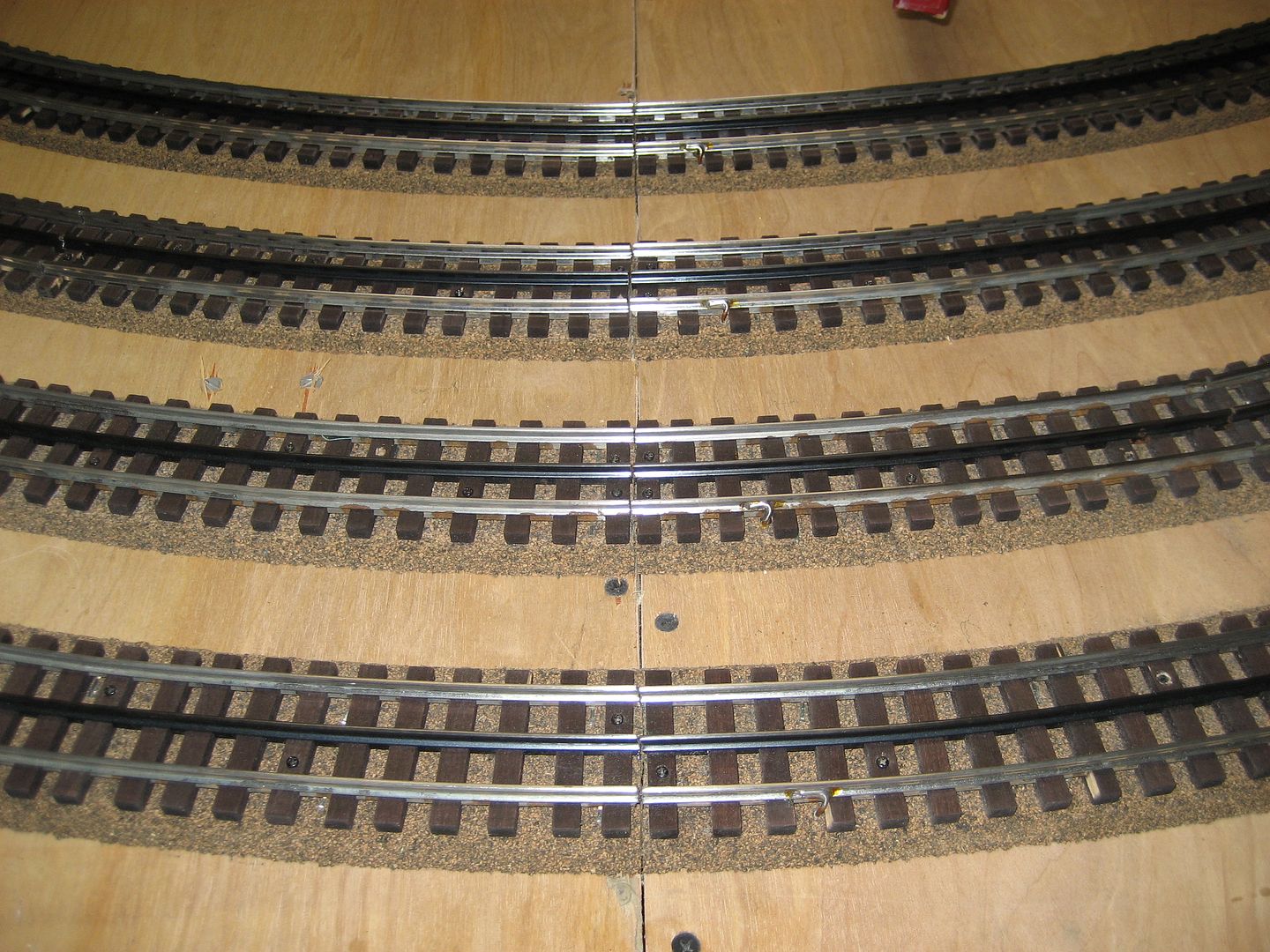

Two modules butt together, note the cut on each of the (4) tracks.

Experimenting once using sections of 027 track as a template I formed curves on the inside of several sections of 027 to create a tighter trolley line curves. I don't know what i ended up with but everything I wanted to run on it ran just fine. Patience is key. My thoughts however when it comes to GG track is if I ever build another layout rather than going with fixed radius curves I would plan on using easements, the flex track is ideal for that.

You can only (easily) bend fresh Gargraves flex track. Once it ages and the ties dry out, it becomes a difficult chore. You can spray old track with WD-40 and try to bend it, but that only goes so far.

Steaming Jon posted:

I have 12 radius curves. O24. I use it to turn a snow plow...check out the video! https://www.youtube.com/watch?v=WXbf05SUnJ0

I have used only Gargraves Flex on three layouts since 1992 and follow the same method at Mike CT for marking centerlines except I use an old metal tape with various drilled radi holes swung on a pivot point to mark the curve centerlines and install cork roadbed to those lines. Then bend the Flextrack until center rail aligns with the cork center line. I typically have wide curve arcs but have occasionally bent to a 16" R for a friends trolley line. I mark my center lines twice, once on uncovered joist tops so I can pre-wire for electrical sites i.e; lighted structures/accessories, Tortoise motors, switch stand lanterns,etc. I then remark on my plywood/ foam cover for track laying. On fastening track except for the ends/joints were two screws are used I tend to separate screws by about 8-9 ties. On 054 and tighter I install screws about 4-5 ties apart.

Swinging a Radi, black Sharpie mark is 084, red 072 curve arcs. Other end of ovals 096/084.

A note on installing flex by bending and fastening every 8- ties apart. As you advance from trailing end joint to leading end, leave screws out about 8 ties back from both trailing and leading ends. Then after bending and screwing every 8-9 ties return to trailing end of partially closed rails where screws are installed only 8 ties back from joint and ease in curve joint with pressure on outer tie ends until precise curve attained. Then install screws 2 ties back each side of trailing joint. Then return to leading end and drive up center and outside rails as needed to close trailing rail joint, but not jamb tight. Then proceed with same procedure installing next 37" curve section. Remember to remove and space ties as needed as you advance with installation. A no kinks installation.

Attachments

If you are trying to bend any used (or stiff) gargraves track, I find that first spraying the whole track with WD40 helps. Be sure to clean the rails afterwards.