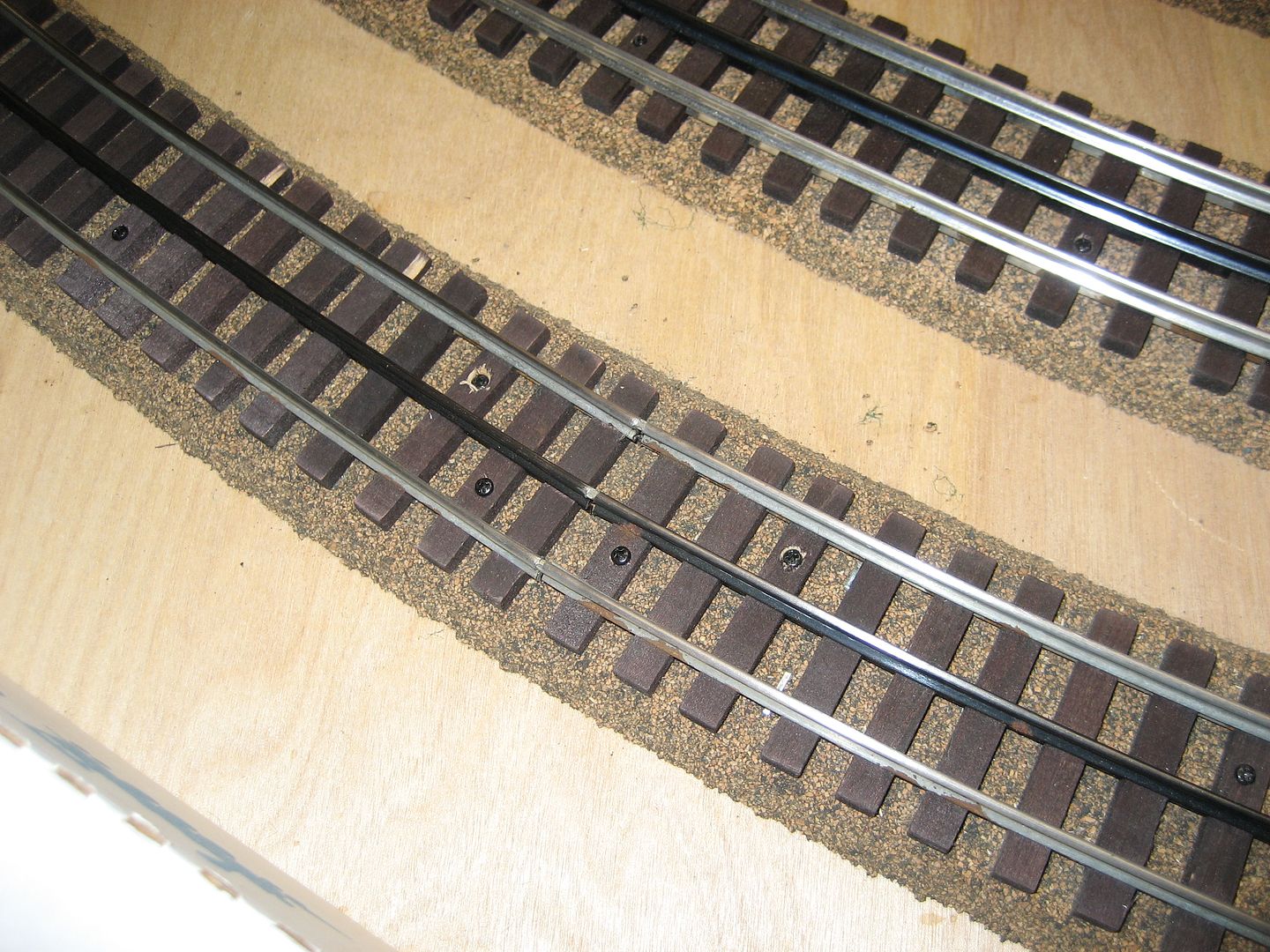

Your method of using a string (trammel) will work just fine to make a nice, even curve with the radius of your choice. However, the goal of some model railroaders is to have 'eased' curves (like the prototype), which involves a constantly shortening radius from the beginning of the curve to the center, then the reverse back to the straight.

This way the loco and the train will 'ease' into the curve a little at a time, instead of going immediately from straight to full radius. Sound complicated? It IS, if you lay it out with varying lengths of string (changing radius every six inches or so). However, there's a MUCH easier way to lay out curves WITH easements, which look really great, and avoids having the consist jerk into the curves. Here's how to do it:

Use a special stick, the FULL length of the curve, plus a coupla feet or more. The stick should be about 1/8" thick (less if you can), and an inch or so in width.

Determine the two points on your benchwork where the curve starts, and where it stops. Drive a pair of finish nails at those points, just enough apart to accommodate your stick's thickness, and another pair of nails about a foot further down the trackline on the straight portion. Do this at both ends of the curve.

Now insert the stick (on edge) between all the nails, and the shape of an eased curve will magically present itself as the stick has to bend to make the curve but, since it's being held straight at both ends will cause it to automatically create the desired easement into the curve.

It's a LOT easier done than written and, in the time it took to write all this down, one could have 'easily' laid out an eased curve, which would be appreciated by not only your trains, but also the viewers eyes.

I hope all that makes sense. If it's confusing, let me know, and I'll do my best to describe it from another vantage point. Once you've done it, you'll slap your forehead and say "Dang...that was really simple, and works (and looks) GREAT!" Or something to that effect...

Hoping that helps more than confuses,

Mark in Modesto