I have two cranes...intermodal (Pic attached) and a TMCC crane. Both have ribbon cables attached that run to the manual controls. I'm not as concerned about the cable on the TMCC crane as I can run it remotely, but the Intermodal poses an interesting problem. The ribbon cable has to be attached to the crane to operate it. I've been puzzling over how to deal with the ribbon cable as the Intermodal crane moves back and forth along the track. I've thought I could cut a slot int the table top and that way the cable could move back and forth with the Crane. I can't think of any more elegant way to deal with that cable. Any and all suggestions welcome. Thanks.

Replies sorted oldest to newest

I've been thinking about adding some cranes for an intermodal myself and was also thinking about this. The crane I was looking at has a 4-wire interface. What I was planning on was one of two solutions both with a similar effect. On the bottom of the crane I was going to add 4 pickup points (like the bottom of a slot car). Then staying with the slot car theme, modifying a slot car track by cutting it down to just the slot and the two pickups on each side. I can fit the two sides, one on each side of the track. This also helps keep my crane to follow a specific path that matches the track. The 4 track lead wires would go over to the controller. Most slot car pickups don't do well in reverse so I might just make them a spring loaded copper strip.

Mike, I lived in the "T" of DT&I ![]() I'm not sure I can visualize your solution but it sounds intriguiging. So the four wires would be split among the four contacts?

I'm not sure I can visualize your solution but it sounds intriguiging. So the four wires would be split among the four contacts?

I have two gantry cranes that run parallel to the table's edge on a pair of common rails (spiked to the homasote) I ran the ribbon cable down the inside of a crane leg and through a slot cut in the table top. Since the cranes are mostly stationary, but can each be moved manually a foot for whatever reason, it works....and works very well.

That said, I've thought about using copper foil tape for this sort of situation. If the accessory can be assured to track consistently in its back-and-forth motion, I believe one could lay down parallel strips of tape on the table top....maybe even an equal number on both sides of the device's span. Then a set of rollers or wipers could be fastened to the legs to make contact with the foil strips.

Disguising the foil strips would be a challenge, perhaps, but every alternative short of an on-board battery with radio control (the new generation of Li-Po's used in drones/planes/etc. are pretty small!) will have some compromises functionally and visually, IMHO. (The slot for my gantry crane cables is pretty well 'hidden' being closely adjacent to the inside of one of the crane rails.)

Just a thought.

Let more creativity begin!!

BTW, whereas I last purchased my rolls of foil tape (I use the tape extensively for routing low power for accessories, inside structures for lighting, etc......VERY handy and quick!![]() ) from Micromark, I just found that they no longer are selling it. No matter....the stuff is available lots of places on line as well as hardware, home improvement, and craft stores (stained glass hobbyists use the stuff extensively).

) from Micromark, I just found that they no longer are selling it. No matter....the stuff is available lots of places on line as well as hardware, home improvement, and craft stores (stained glass hobbyists use the stuff extensively).

FWIW, always....

KD

There are multiple solutions to this in real life that may translate to scale. The cranes on our turbine deck have a power cord on one side that spools up on a wheel that keeps a light tension on the cable.

Other places use a slide shoe type contact where the slides travel with the crane and the conductors are elevated and arranged in such a way to keep the conductors from being exposed.

Both of the examples above are good for cranes with intermediate or long travel distances. For a shorter travel distance, a cable laid out parallel to the travel axis in a flexible guide that bends or itself is another option.

I think a scale version of any of these would be good. If you are familiar and comfortable with the slot car contactors I say go for it. The only thing I think might be problem in the long term would be dust or debris in the slot tracks.

Make it look industrial. A split wire loom in 1/4" diameter would look like a fuel line or something or perhaps the braided loom that would have to be a diameter large enough to pass the connector, but would be a more flexible and smooth.

Idea #2 Electric RR Mini Commander ACC or 2 to make it TMCC controlled. How to get power to it is the issue there.

Edit: I watched some videos of it in action. three motors to control with variable voltage forward/reverse, hook up/down, hook left/right and one on/off for hook open/close. One French guy put a DCC decoder in it, but only for the crane hooks left/right & open/close.

Hi Ed, I also agree with JHZ563 & KD's options. I have not gotten nearly as far as you have so mine is still in the "thinking" phase. The two pictures below might help. The slot track on the left shows a couple of leads soldered on (you would go from the bottom). Then down one of the sides of the wheel for the crane you would attach an angled bracket (with likely some weight on it) going over to a slot car shoe (shown on the right). If you need 4 leads you would repeat the arrangement, maybe down the other side of the crane. As the crane rolls it moves down the slot keeping all four leads in contact without trailing any wires.

Attachments

I used the slot technique on my gantry crane. Easier to hide due to the rail. You could hide the slot for your crane by using linear brushes used to close off windows and painting to match your concrete.

Example

My crane is actually powered through the slot by a spring copper strip attached to one wheel. The cable is attached to the metal strip and moves with it. You could attach a metal strip in similar fashion so the wire would follow the wheel.

See the wire or slot?

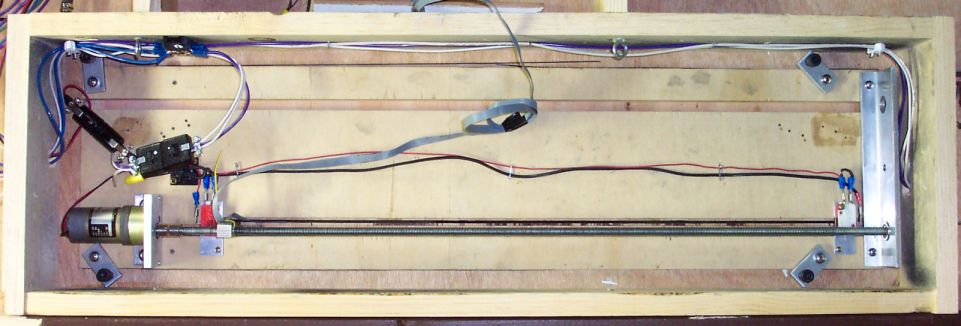

This is what is under the table.

Another shot of the crane.

Pete

Thanks Gents! Great alternative solutions. Pete, I can't see the wires! Excellent. Carl, the split wire loom may be exactly what I need to disguise the cable on the Intermodal. Well, I have my work cut out for me (no pun intended). Thanks again. I'll post when I finish...i certainly hope it looks half as good as the pics I see here.

Pete,

I'm not sure I understand the "under the crane shot..." It looks like you may have the same crane I do...big controller for boom movement but only manual movement of the crane along the track but you've 'motorized' movement along the track like my Intermodal crane? if that's right I'd like to try to do the same as well, but I haven't a clue how to do so. thanks,