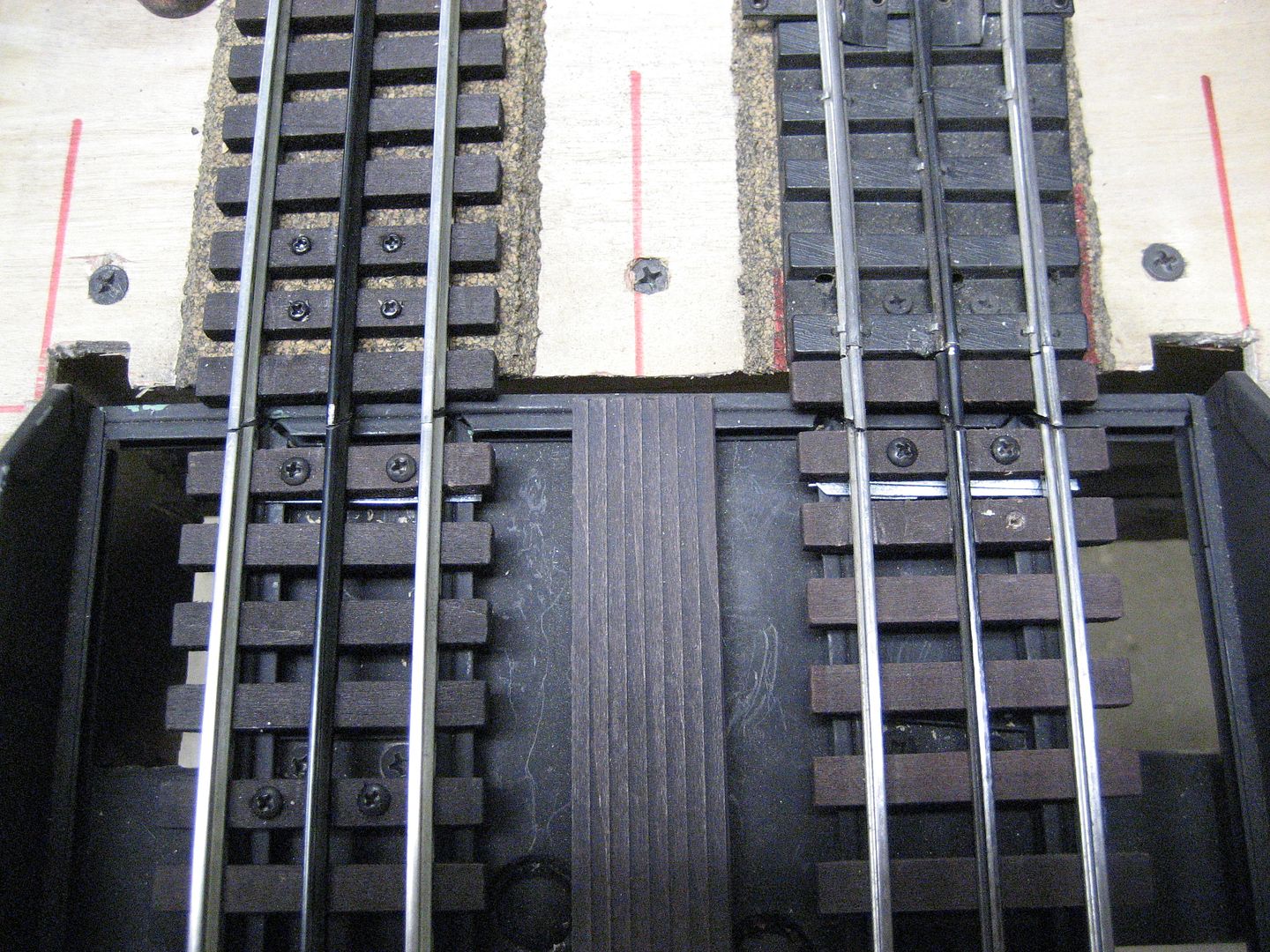

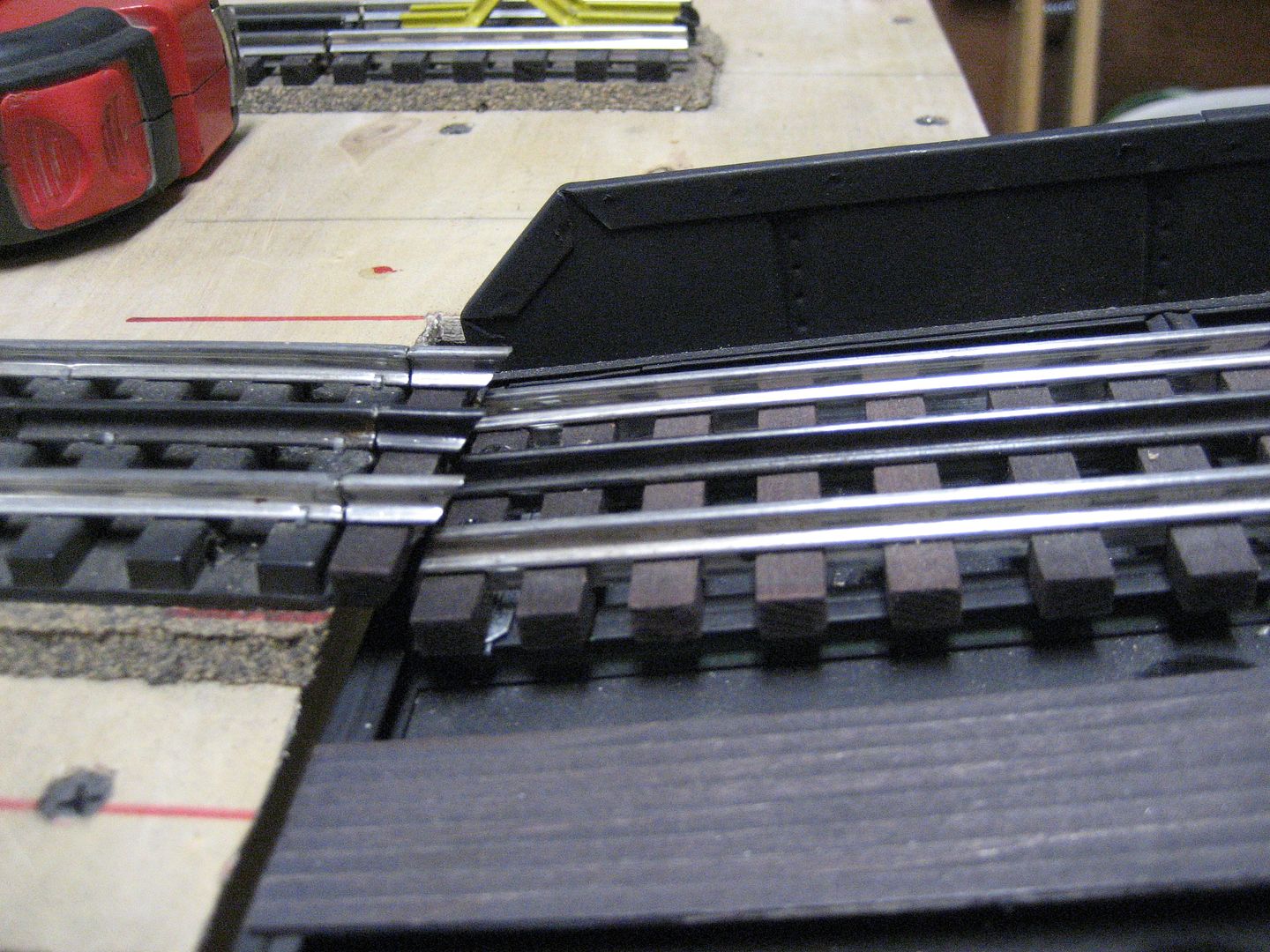

I've read Jim Barrett's articles on lift-up bridges, and am wondering if a lift-out bridge would be simpler/easier and more effective. I am finishing the benchwork on both sides of my utility room door and hope to start with the bridge next week. A lift out bride would need electrical contacts and precise alignment when installed - I am thinking it would need grooves to sit in for that. I think I'll probably go with the lift-up bridge like Barrett did in his existing layout, but want to check with you all to see what you think. BTW: I don't recall any articles on lift out bridges, but memory is not as good as once was.

Thanks.