I have successfully used Lionel 45 and 90 degree crossings with Marx engines with the huge drive gears by cutting and filing down certain areas of the crossings. Using an Xacto knife cut slivers out of certain areas and then finished up by smoothing with a small file. I have had no problems with the 90 degree crossings. The 45 degree crossings have a longer "dead" area and occasionally certain engines will kick into reverse. The "dead" area is caused by the outside rails loosing power and not the center rail as the engine travels through the crossing. One way to reduce this is to make sure that the tender or car that is right behind the engine has very clean coupler connections with a very clean engine coupler connection. This allows electricity to flow from the outside rails of the tender, through the couplers to the engine as it passes the "dead" area. On one of my Commodore Vanderbilts I ran a wire from the tender frame to the engine frame and have had no problems going through the 45 degree crossing. I have another Commodore Vanderbilt with no modification that has no problem going through the crossing so perhaps the clean coupler connections have solved this one. I also have Marx engines without reverse units and the momentary loss of power through the crossing isn't enough to stall the engine on the track.

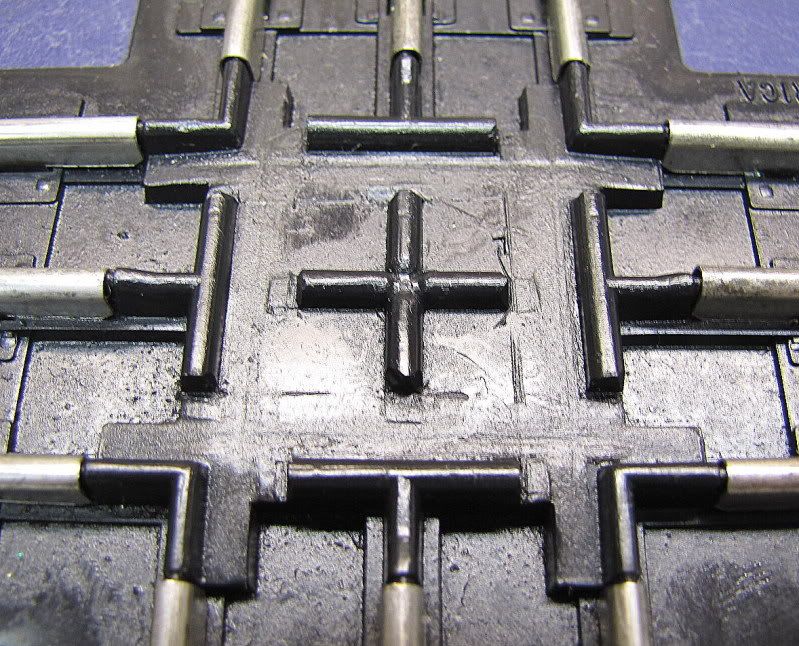

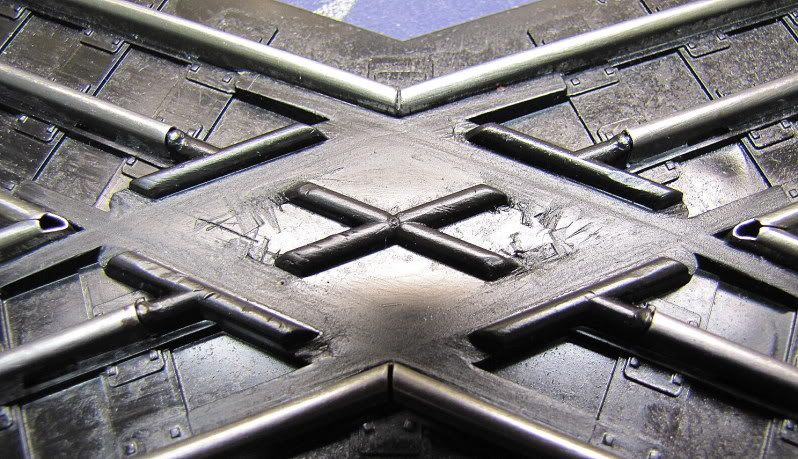

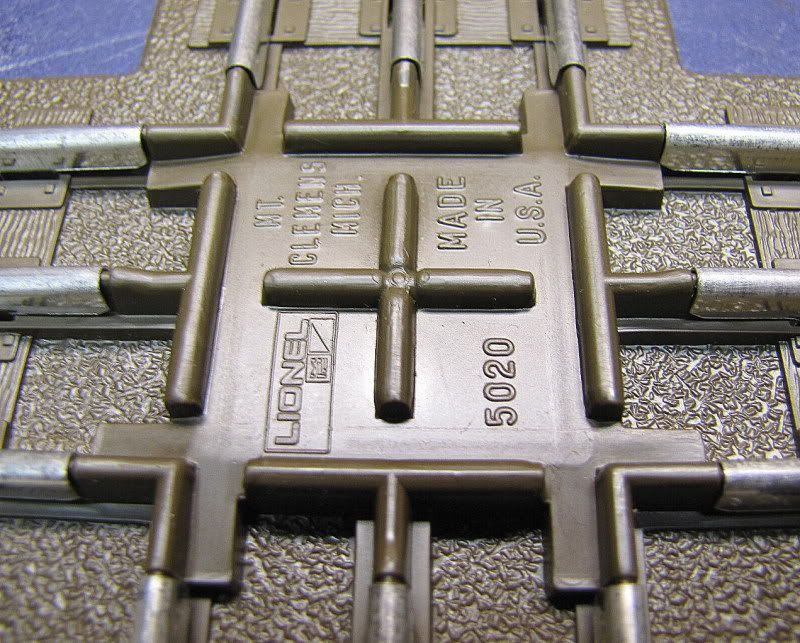

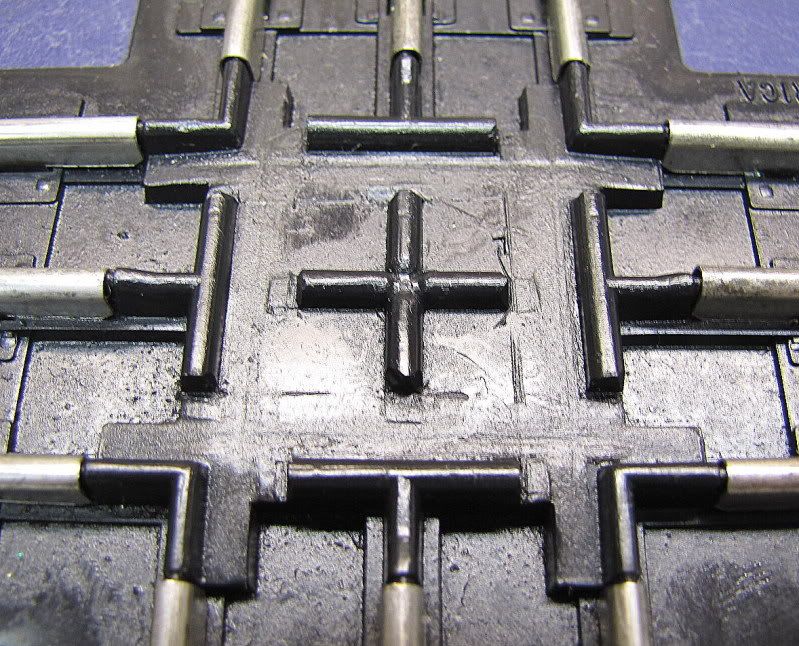

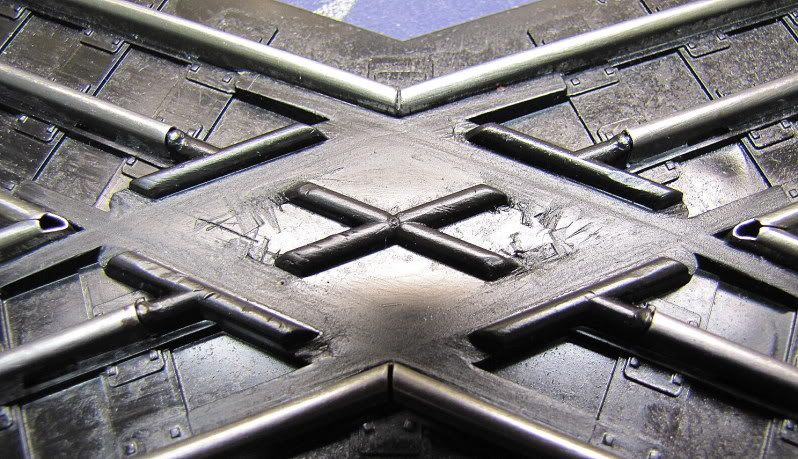

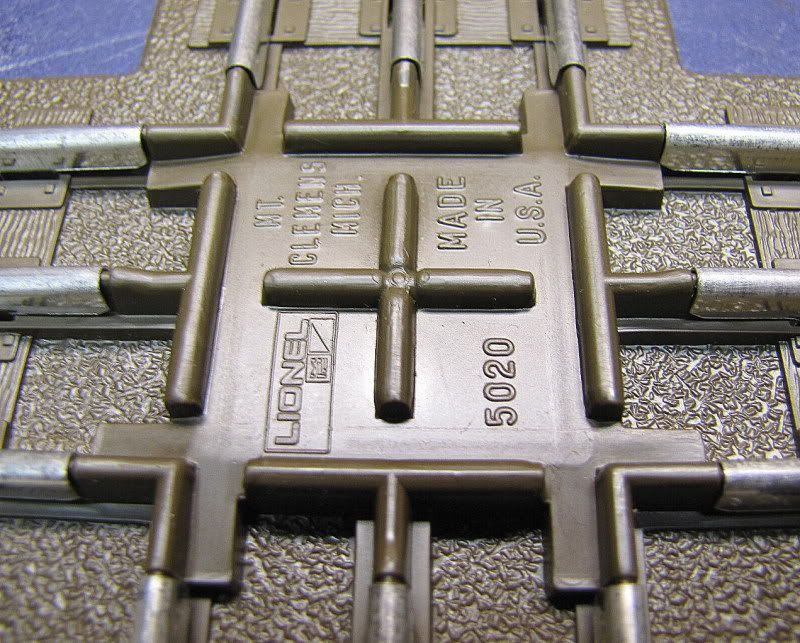

Here are the photos that should explain which areas that need to be cut out.

Lionel origional 45 degree crossing.

Lionel 45 degree crossing with cut aways for Marx large gear engines.

Lionel origional 90 degree crossing.

Lionel 90 degree crossing for Marx large gear engines.