To avoid bearing marks along finished template surfaces consider using a square router bit bearing. The bit just slides along the pattern face. The movement is internal.

|

|

To avoid bearing marks along finished template surfaces consider using a square router bit bearing. The bit just slides along the pattern face. The movement is internal.

Replies sorted oldest to newest

If you make sure that the bearing race is clean you will not get the burn mark. If it does burn that means the bearing is spinning with the tools revs. The bearing should just glide along the surface at the same speed that you are moving the tool. The square guide will not do inside corners.

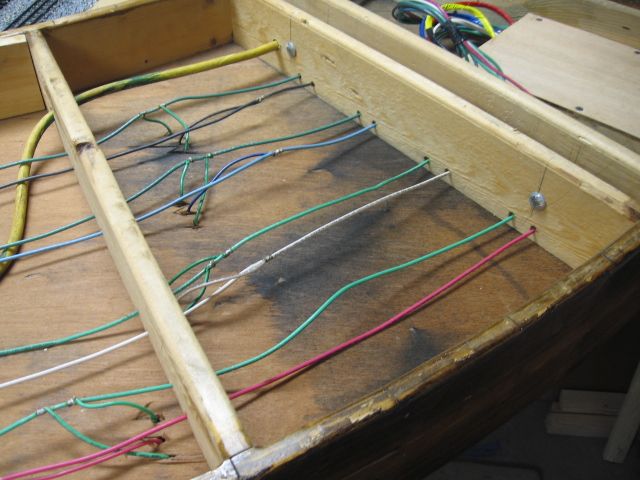

The thought here was for a smooth trimming of the decking to compliment the benchwork side frames.

In benchwork building we rarely would ever encounter the design constriction of a 90 degree inside corner. We always use an curved radiused corner to accommodate smooth flow of people or right of way.

Hi Ralph, Thanks. Since going to square bearings 5 years ago I have no more maring problems. Here is the square bearing bit source, White side machine:

The bit is also available with 1" flutes under another part number. Give them a call. they are very helpful.

The bearing I use is Whiteside part# B3SQ 1/2" square 3/16 inside diameter.

I missed you at Strasburg, stop by my tables in the engine house this April. Tom

Working with very smooth soft wood even a new round roller tends to leave a mark.

The square roller, which can be installed on any pattern bit, are like magic, totally non marring.

Curves are usually no problem. We also use a round-over router to remove all square edges from portable modules. Easier on the hands. ![]()

Access to this requires an OGR Forum Supporting Membership