My brother and I have just finished working on a table in my outbuilding for a layout, I have a space that is 8' by 15 feet, 10 inches. It's not quite 16' due to one of the boards I used from an old shelf being 94 inches long instead of 96. I wanted to go around the wall in the room but wasn't able to, so this is what I have to work with.

I have modern O scale stuff since I want to model what I see in real life when I go railfanning. I have enough Lionel Fastrack to make one loop at the moment, I just haven't bought any extra track yet. I'm still trying to research on what materials will deaden the sound from trains moving on Fastrack sitting atop a wood surface.

http://www.atlaso.com/O%203Rai...%20web/pages/O27.htm

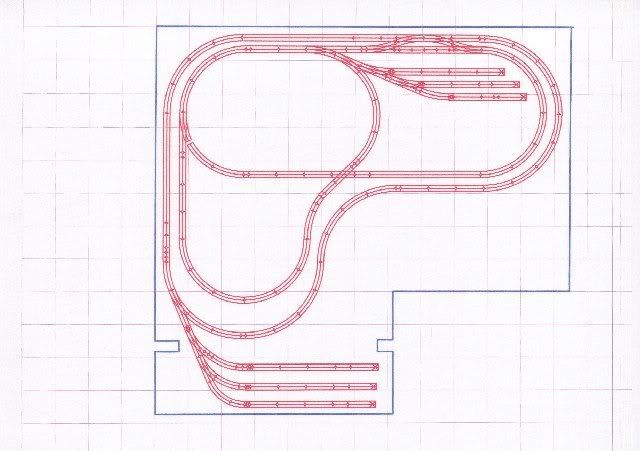

I liked the idea of this Atlas O plan (small yard and siding at the front), but with a 3 foot gap in the middle now I can't really put anything in the middle of the layout like the plan shows. I don't have to have any fancy operations, just a few spurs for switching and a small yard used mostly to park trains. I'm thinking I can make a few tweaks and still have something similar to this trackplan though. As far as the corner of the 4x8 in the corner, I think I'll carve a hillside out of foam and slide it over there so I don't have to reach to put anything over there!