Hi guys,

I was asked to share my information regarding my use with Alclad2 on model Budd and Pullman Standard passenger cars. I really enjoy this process and am always glad to be of help anytime. I've been experimenting with Alclad2 since the mid 2000s and along with several other modelers have been providing Alclad's owner, Mr. Tony Hipp, with feedback. The steps I've used apply to N, HO, S, and O scales. Originally modelers complained of Alclad2 finishes appearing too dark, when compared to the prototypes. After some experimentation, I discovered that the key change required was to switch from black basecoat colors to gray basecoat colors. The basecoat is the foundation used underneath the Alclad2 metalizer.

I realize that this is an O-Gauge forum, but the purpose here is to show the Alclad2 application process. I hope you don't mind. The unit below is a past project that I did for a friend of mine, a Santa Fe and BNSF modeler ( I've forgiven him for that, LOL!)

A. Subjects : 1980's production HO IHC dome car and an HO Bachmann full length dome car. The models are based on prototype Santa Fe units.

1. Paint Stripping. After removing the shells from their chassis', they were immersed in a 91% isoporpyl alcohol bath. After soaking approximately 5 to 10 minutes, the factory silver paint lifted off as I scrubbed thoroughly with a toothbrush. After stripping, the shells were washed with a generic version of Dawn dish washing liquid.

NOTE: You should not use soaps that contain lanolins, aloe, or other strong moisturizers as that could weaken the adhesion of the paint that you will be applying on the shell later.

2. Basecoat Color (foundation) - Scalecoat 2, New York Central Light Gray. Thinned 50%-60%. Airbrush Paasche VL. Needle and aircap sizes: #3 (medium). Air pressure at tip: 25psi. Spray Distance to shell: 3" inches. Total number of coats: Two, medium wet.

3. Critical stage: Gray finish must be SMOOTH and GLOSSY!* After drying; check the shell for dry or rough spots. If mistakes are discovered, this is the time to fix them. Wet sand dry or rough spots. Clean and apply another coat over shell if needed. When finished, flush out & clean airbrush with lacquer thinner.

*For those not using a high gloss gray, you can apply Alclad's High Gloss Clear Base #303. The foundation must have a smooth high gloss surface to obtain the realistic effect provided by Alclad2's natural metal finish

4. Interior: As the basecolors cured, I took the molded plastic seating modules that were inside the dome sections and hand painted them with Polyscale acrylic colors based on photos I saw from a Santa Fe modeler .

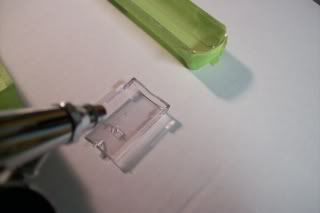

5. Alclad Application - Formula: #107. No thinning. Airbrush Needle and air cap sizes: #1 (fine). Air pressure at tip: 15psi. Spray distance to shell: 2" inches. Number of coats: 3. FIRST, I spent a minute testing myself on the back section of a scrap FP45 shell to check that my airbrush was spraying well and that my distance/stroke speed were good. This step is a headache preventer as I discovered that I needed to increase my speed, slightly.

5a. Test Check:

As you apply the Alclad2. ---> Relax and enjoy! (I had my smooth jazz tunes playing) Maintain the airbrush parallel to the surface. Spray horizontally in a LIGHT MIST COAT pattern, never "wet it". For the sides and roof, stroke your airbrush as if you were painting with a modeler's paint brush. For the ends, stroke vertically, also in mist coats. DO NOT PILE IT ON.

TIP: ( Wearing an appropriate respirator) As you spray, keep your head within 10" of your model, but over it, and either to the right or left of the airbrush so you can monitor your speed and distance. Some modelers have a tendency of standing directly behind the airbrush while spraying and not clearly seeing if they're getting too close or far. (yes, been there, done that!) Wait a minimum of 5 minutes between coats if the temperature is over 75F. Wait longer at lower temps. Check your shell(s) carefully for any areas missed; and stroke over on the next coat if needed. Flush out and clean your airbrush upon finishing

Note: Your 1st coat will appear almost invisible but don't worry, it's there. Your 2nd coat will be quite noticeable and you should be smiling by your 3rd mist coat. Practice this on a small scap of plastic first. Compact disk cases are excellent for airbrush practice. With practice, you'll be able to properly cover passenger car shells with just 2 mist coats of the natural metal finish.

7. Sealing/Toning down sheen - Instead of Future Floor Finish, Testor's Acryl or Pollyscale clears, I applied *Alclad's NEW waterbased clear; #ALC 600. Thinning: None. Airbrush needle & aircap sizes #3 (medium). Air pressure at tip 20 psi. Distance 3" inches. Number of coats: One:

In addition to sealing the metalizer and toning down the sheen, the clear will provide the foundation for decals. After testing my airbrush on the scrap FP45 shell, I applied the Aqua Clear to the shells. I was impressed with how finely this atomizes and smoothly lays on top of the Alclad finish. IMHO, this performed superior to the clears I've used before, including Future. However, upon finishing the airbrush should be cleaned asap. I used a mixture of distilled water and alcohol to flush out.

* If you prefer a solvent based clear instead of waterbase, you can use Alclad's ALC #310 High Gloss Clear.

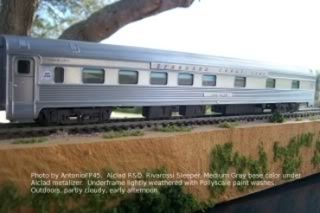

The sheen toned down beautifully, imho, to a natural metal appearance of highly polished, reflective stainless steel. Only one coat was applied since this will be the foundation for the Santa Fe decals. Afterwards, 1 to 2 more coats of clear will seal the decals and tone down the sheen more. These are shots before re-assembly:

9. Window Tint: ( only the full length dome's glazing was tinted)

I applied Alclad2 #408 "Armored Glass" to simulate the green tint on the windows. I tested a couple of transparent scrap pieces. I then airbrushed the tint on the "inside" of the one-piece window sections (upper and lower). When I first applied the tint to the lower piece, it hazed up. However, it leveled out nicely with a 2nd coat. Tony Hipp from Alclad, explained to me that in high humidity conditions the older formula tints blushed. This does not occur with the newer tint formulas that were released last year. My camera doesn't do it justice. Overall, I like it and plan on using this tint on my Walthers cars.

10. Re-assembly: After lightly weathering the underframe and diaphrams, white styrene strips were positioned and glued in place to resemble window shades. Dome interior seat module was reinstalled and body installed on to chassis.

[u]OUTDOOR PHOTOS:[/u]

Light weathered rust/grime on diaphram compared to a prototype unit.

Prototypes and Models:

Finished results:

These inexpensive cars were fun to to do and look quite nice running on my friend's layout on his freelanced BNSF OCS train.

Imho, passenger rail car modelers starting out with Alclad2, should not feel intimidated as this product is easy to use. Consider practicing on small scrap styrene pieces or smaller scale discarded rail car shells so that they you may fine tune your techniques the decision is made to "go for it".

BTW: Good news is that Alclad2 will shortly be introducing new basecoat gray colors. So instead of waiting 3 to 5 days for Scale Coat 2 to cure, the Alclad basecolors dry and harden in 20 minutes in 75+ degree temperatures.

More details will be forthcoming.

High Greens ![]()

![20130512_191153-1[1] 20130512_191153-1[1]](https://ogrforum.com/fileSendAction/fcType/0/fcOid/16494189560427588/filePointer/17479526110142340/fodoid/17479526110142336/imageType/MEDIUM/inlineImage/true/20130512_191153-1%255B1%255D.jpg)

![20130512_191153-1[1] 20130512_191153-1[1]](https://ogrforum.com/fileSendAction/fcType/0/fcOid/16494189560427588/filePointer/17479526110142340/fodoid/17479526110142336/imageType/SQUARE_THUMBNAIL/inlineImage/true/20130512_191153-1%5B1%5D.jpg)

![20130512_191139-1[1] 20130512_191139-1[1]](https://ogrforum.com/fileSendAction/fcType/0/fcOid/16494189560427588/filePointer/17479526113103012/fodoid/17479526113103009/imageType/MEDIUM/inlineImage/true/20130512_191139-1%255B1%255D.jpg)

![20130512_191139-1[1] 20130512_191139-1[1]](https://ogrforum.com/fileSendAction/fcType/0/fcOid/16494189560427588/filePointer/17479526113103012/fodoid/17479526113103009/imageType/SQUARE_THUMBNAIL/inlineImage/true/20130512_191139-1%5B1%5D.jpg)

![20130809_202339-1[2] 20130809_202339-1[2]](https://ogrforum.com/fileSendAction/fcType/0/fcOid/16494189560427588/filePointer/20717517859645008/fodoid/20717517859645004/imageType/MEDIUM/inlineImage/true/20130809_202339-1%255B2%255D.jpg)

![20130809_202339-1[2] 20130809_202339-1[2]](https://ogrforum.com/fileSendAction/fcType/0/fcOid/16494189560427588/filePointer/20717517859645008/fodoid/20717517859645004/imageType/SQUARE_THUMBNAIL/inlineImage/true/20130809_202339-1%5B2%5D.jpg)