Well, my layout table is finished. The table top consists of 3/4" plywood covered by 2" rigid pink foam. The track plan is finished and the MTH ScaleTrax has been purchased and laid out on the layout. The track plan looks good in the flesh! So far, so good. Now for the last step before permanently mounting the track... the roadbed. My initial thoughts were to go with the Black Track Tape (double sided adhesive tape) for the roadbed. I like the low profile look of it and the supposed ease of laying the track and ballast on it. However, in the back of my mind, the knowledge that so few people use it compared to those using cork roadbed is causing me to give a second thought to the roadbed prior to finalizing things. I've also read where some folks have laid the track directly on the foam without the use of roadbed whatsoever. I personally feel roadbed of some kind is necessary.

So I am looking for some last seconds thoughts from you guys as far as the double sided tape versus cork. At 67 years old, I'd like to get it right the first time. Thanks in advance for any input!

Replies sorted oldest to newest

Hi Paul, you should take a look at Woodland Scenics vinyl roadbed. It is one piece and conforms easy to track contours. Easy to work with, comes in a roll. I use it frequently on the NJ Hirailers layout.

Hey... Another Paul! Paul, I like the look of the vinyl roadbed that you suggested. Did you tack the roadbed to the layout board or did you glue it? Then, did you tack the track to the roadbed or did you glue it (as the video shows on Woodland Scenic's website)? Lastly, what did you do as far as ballast... simply glue as normal? Overall, it looks nice! Thanks for the tip!

I just fit the vinyl roadbed under the track in position and screw the track down. Very simple. You can ballast it using the usual procedure with the glue, etc.

Sounds good... straight forward and easy! I think I'll give it a try! Thanks Paul.

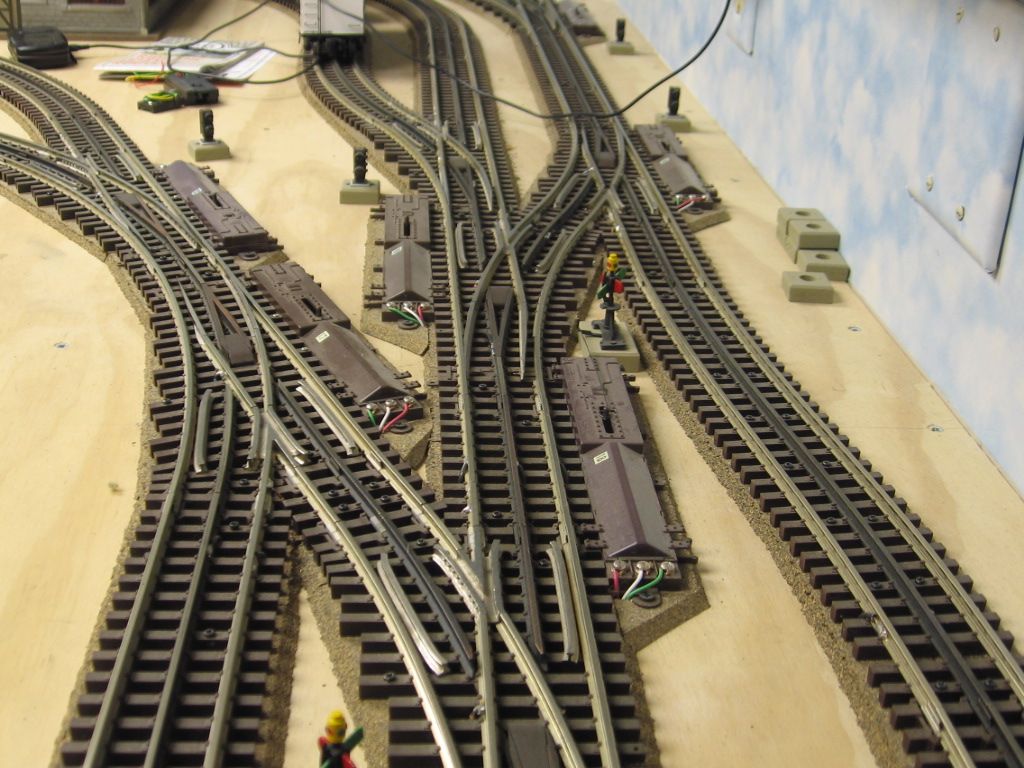

This was done with Midwest cork. Used Gargraves flex track, used Gargraves and Ross switches. Even some of the cork was used.

Mike, what did you secure the cork with?...Glue?....

I also use the Woodland Scenics roadbed on top of styrofoam and secure the roadbed with two-sided carpet tape. A couple of three or four inch strips under the roadbed. I also secure the track to the roadbed the same way. I'll usually add a screw to hold the track just at the apex of a wide curve to start.

These are some early construction shots:

Attachments

Brian, you use 3" to 4" strip of carpet tape to secure both the road bed and the track along with an occasional screw where needed. Do you use a piece of carpet tape for each piece of track? I assume that you can ballast over the roadbed/carpet tape mix without any noticeable changes in the way the finished track looks. One of my concerns is using any sort of glue on the track... If I need to pull it up for some reason, it could be a mess. And as I'm sure you know, track these days is not cheap!

Thanks... more to think about!

BTW, I like your elevated sections of track! That's going to make for some some great scenary!

Mike, what did you secure the cork with?...Glue?....

Stapples. once the track is secured with screw, so is the cork.

Once track is in place, I have pulled screws and installed the cork under the track and switches.

Ahh ok I gotcha...thanks Mike.

As do I use Woodland Scenic's Trackbed. If you use screws to hold your track, the track will compress the foam just enough to secure the roadbed under the track. I do not use screws in switches so a little glue is used there to fix the roadbed in place.

Jim, I understand you to say that you use a screw through the track to hold the road bed to the table and when you have a turnout, you glue the road bed to the table and let the turnout "float" on the road bed secured only by the rail connections of the turnout to the connecting track. You don't have any problems with the turnout shifting around over time? I have a ScaleTrax double crossover on my layout.

I'm wondering if I secured the crossover and the two 10" straights that I could let the (4) turnovers "float"? Again, I really do not want to glue the turnouts and screwing them could cause operational problems. I guess I'd start out be letting them "float" and see what problems I run into.

I use Atlas track and switches. I screw the surrounding track just enough to begin compressing the trackbed. This will fix the switch from moving horizontally but floats perpendicularly, if I can use those terms to describe the switch's movement. LOL

I used Woodland Scenics Foam roadbed and screwed the track and switches through it to the plywood,has worked well for 10 plus years.

Mikey

I use Flexxbed on my mainlines and am very happy with it. It bends and contours very easily. I've even transferred it from one layout to another without any issues. I painted it with "stone" spray paint and put ballast between tracks.

Brian, you use 3" to 4" strip of carpet tape to secure both the road bed and the track along with an occasional screw where needed.

The Woodland Scenics roadbed I use comes in a 24 ft. roll. I cut it into more manageable 2 foot strips. After laying the track where I want it, I put a 3 or 4" piece of carpet tape at each end of the 2 foot strip and slide it under the track.

The screw I use at the apex of the curve just to hold it in place to line up the track and keep it still to start.

Do you use a piece of carpet tape for each piece of track?

For my Atlas O track I put the carpet tape strips under every other track joint. For longer 40" straight tracks I add some tape in the center of the length. It doesn't move and is easy to pull up if you need to make changes. No track problems for me since installation in 2004 and trains run very quiet.

I assume that you can ballast over the roadbed/carpet tape mix without any noticeable changes in the way the finished track looks. One of my concerns is using any sort of glue on the track... If I need to pull it up for some reason, it could be a mess. And as I'm sure you know, track these days is not cheap!

You're right about the mess with glue! I haven't got that far yet, but for ballasting I plan to also use the carpet tape. As taught to me by the late Kirk Mitchell from JusTrains, I'll use 1" wide carpet tape and attach it to the side profile of the roadbed. Then add some ballast and press it into the tape. The track ties will hold the ballast between the rails and outside the rails up to where the tape holds the ballast.

If you need to make changes or pull up track for any reason, you can vacuum up the loose ballast with a mini vac and save it for re-use, then pull up the tape. Track will be clean and reusable.

Thanks... more to think about!

Lots of fun!

BTW, I like your elevated sections of track! That's going to make for some some great scenary!

Thank you Paul! That's what I'm hoping for!

Just wanting to thanks all those who replied! I got some great tips among which there are any number of ways which work fine. Well, now to order some materials and get the old rial gang (me) working on laying some rail! ![]()