anyone have any pro's and cons of a turn table verse a transfer table

Replies sorted oldest to newest

I would think the biggest difference is that turntables work better for steam engines since you can turn them around. Can't do that with a transfer table.

thanks never really see a tranfer table on layouts i was wondering if operation isnt

the best also i only know of a post war one did lionel remake one or anyone else for that matter

Layout real estate taken up and length of engines to be used with. One additional function the turntable provides- spinning an engine 180 to turn it around.

Both are limited by the length of the moving track.

Turntable has a bunch of angular tracks around the circumference and potentially can take (waste because of angles) up a lot of area. Say if you have a 24 in turntable (standard Atlas), then OK a 24in diameter circle + additional tracks ideally are 24 + inches long and radiate like spokes.

A transfer table also has a moving track length and siding tracks would be minimally that length plus some amount. That said, side by side parallel tracks can be closer together and because they are dead straight- higher density or less table area used. Conversely, could be said, more tracks and thus engines stored in the same size area when compared to angular tracks exiting a turntable.

@mutz posted:... did lionel remake one or anyone else for that matter

Lionel Product No. 6-14113. Last catalog: 2001.

Mike

very cool ty

Ross also makes a transfer table.

Transfer or turn table either one the best out there are Millhouse Studio's. I have a 32" Millhouse and love it. As mentioned above it takes up a HUGE area especially if you want a round house to go with it.

@CurtisH posted:Transfer or turn table either one the best out there are Millhouse Studio's. I have a 32" Millhouse and love it. As mentioned above it takes up a HUGE area especially if you want a round house to go with it.

Just upgraded from 28 to 34 inch myself.

With regard to space (or lack of it), l have seen some tiny prototype turntables used for railbuses, etc. But l have wondered if there have been any prototype semicircle turntables, that would turn a loco 180°, but just half around and back, maybe taking up slightly more than half the space, say, at the edge of the layout?

Whatever the length of item being turned 180 degrees plus about two inches would be the smallest you could fabricate if building one. But remember you still need some tracks off it even if only in one quarter of the circle. AND it will always be a circle!

Vernon Barry

Yep I went with the biggest right off the bat! Was interesting lifting it in place 36" by myself. I used a floor jack and some blocks. I am NOT sorry for going that big but man does it chew up the real-estate.

Space is always a problem in any scale and people usually have all kinds of equipment stored on shelves which has to be handled and moved to the layout. Many years ago for a friends N-scale operations layout I built a four foot vertical staging area on his one free wall (tiny room) This opened up layout space for more industries since interchange traffic was easily stored off the layout. The vertical yard was operated by hand crank along with a solenoid to align the tracks. I've though about something similar for O-scale but since I don't have an operational layout it isn't needed (yet).

-Mike in NC,

Attachments

From a prototype perspective, the Turntable is better for steam for 2 reasons. First you want turn them which is easy with a TT. Second most of the maintenance is on the loco end, and the front end of that, so whisker tracks close together at the TT but widening out in the roundhouse allow the maintenance space around the loco part. A transfer table works fine with diesels, and is probably preferable for the maintenance reason and space issues. On a diesel, the maintenance can be anyplace along the whole length, so you need space around the whole thing. This means you want parallel tracks in the engine house with easy access along the whole length. also, generally only one diesel unit at a time needs to go into the house, the length of track in house can be shorter, or can accomodate 2 units.

When you search for specific info on train stuff, a lot of times you get modelers pages, so you have to dig a bit to find 1:1 scale info. I have some pics in my book collection of turntables feeding a round house, but also another track off of it to a transfer table and multiple stall type back shop. I found this interesting link to the Altoona shops and their capabilities. I was impressed with a 6.5 day frame up rebuild of a diesel loco.

@NJCJOE posted:

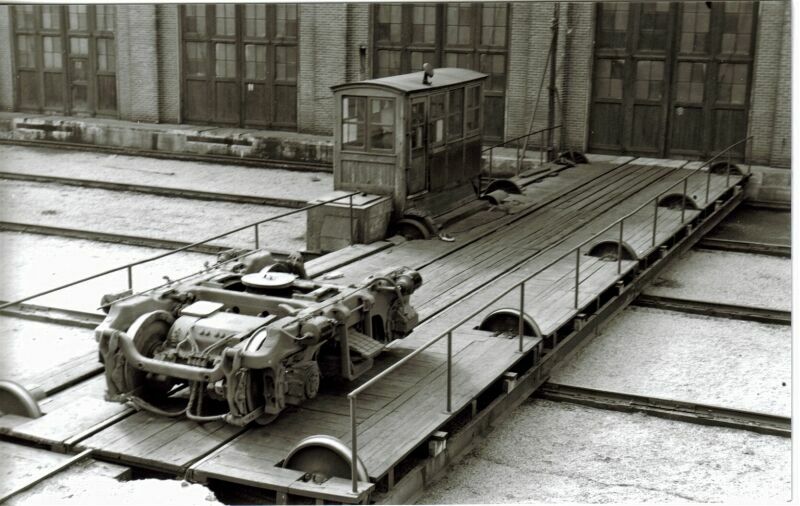

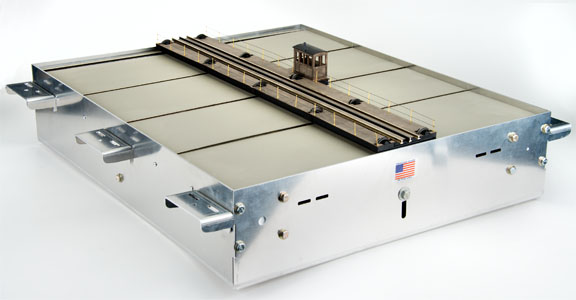

Thanks Joe! When we set out to produce our transfer table we were asked to make a scale transfer table like the prototype. Prototype photo (B&W) is what we modeled our transfer table after. As you can see in the photo the transfer table pit is very shallow 2 feet deep compared to a turntable pit of 8' deep and the bridge is also shallow with many rails and wheels to carry the weight of the locomotive. The turntable bridge girder sides are supported at three points the center pivot and at each end to carry the weight. Here are a couple photos of our scale transfer table. A couple of points I would like to point out about our transfer table is that it has duel drive that moves the bridge, so no matter where the weight is on the bridge the bridge always stays square to the pit. At York , we even drive a Lionel die cast Genset diesel on the bridge while moving the bridge showing the weight shift has no effect on the operation or power/ communication. We also only make our transfer table in one length, 28" long bridge to accommodate all the O scale diesels or a scale passenger car and a switcher on the bridge, since the transfer tables were generally used at diesel & car shops and steam engines typically were moved on turntables. Last point, our transfer table is built from aluminum!

Have a great day everyone and if you have any questions feel free to ask me.

Wooden style transfer table & wood cab (non weathered)

Modern transfer table version with diamond plate decking and riveted cab (weathered version)

Forum member Don's layout with our transfer table in operation

Why not both? LOL. Depends on your: space and needs. One isn't "better" than the other. The prototype does what is most efficient. (Supposed to anyway! LOL)

Oops..,."armchairing" didn't work! No way to avoid a full circle of real estate, to reverse a loco, with a turntable. Maybe back to a "Y" around the engine house in plans. Those, too, eat space, but in different amounts and spaces.