I have recently added to my train table and wanted to add sidings. I’m not sure what degree switch I would need to make a siding. I wanted a few sidings but not sure to due to my opening.

Replies sorted oldest to newest

I use Atlas 21st Century track.

We really need more information to assist with this determination. We need to know what kinds of sidings you want and how much clearance you need for your equipment. Do you have scale equipment?

Do you just want a few sidings or are you building a yard with a ladder?

It looks like you have Atlas O track. They have many sizes of switches. IMHO #5 and #7 switches look great but also require the the most amount of length. You can get curved switches just like your curved track, O-72, O-54, etc. That reduces some of the math to work out if you match switches with your curves.

Ron

We really need more information to assist with this determination. We need to know what kinds of sidings you want and how much clearance you need for your equipment. Do you have scale equipment?

Do you just want a few sidings or are you building a yard with a ladder?

It looks like you have Atlas O track. They have many sizes of switches. IMHO #5 and #7 switches look great but also require the the most amount of length. You can get curved switches just like your curved track, O-72, O-54, etc. That reduces some of the math to work out if you match switches with your curves.

Ron

Basically, I want a straight siding to come off my inner straight track by my opening in the table. Both main line tracks(in the picture) will go straight and curve at the end....045 and 054 curves.

I have Lionel and MTH and I have O scale.

I'm not sure what switch i need to make sure i keep it within my opening.

sorry I’m not good at drawing

Attachments

Thanks

Your drawing shows it stopping at the opening. If that's the case, use anything you want. Do you want the track to stop at the opening or continue between the mainline and the opening?

If you want it to go between, what is the distance from your inner most track to the opening? Measure from the center rail. Track should be roughly 4" apart from center rail to center rail.

Ron

Attachments

Ron045 posted:Your drawing shows it stopping at the opening. If that's the case, use anything you want. Do you want the track to stop at the opening or continue between the mainline and the opening?

If you want it to go between, what is the distance from your inner most track to the opening? Measure from the center rail. Track should be roughly 4" apart from center rail to center rail.

Ron

I measured 15 1/2 inches from inner most track center rail to my opening. I want my siding to go past my opening. I was thinking start with R/H 036 then L/H 036.

thank you for helping me.

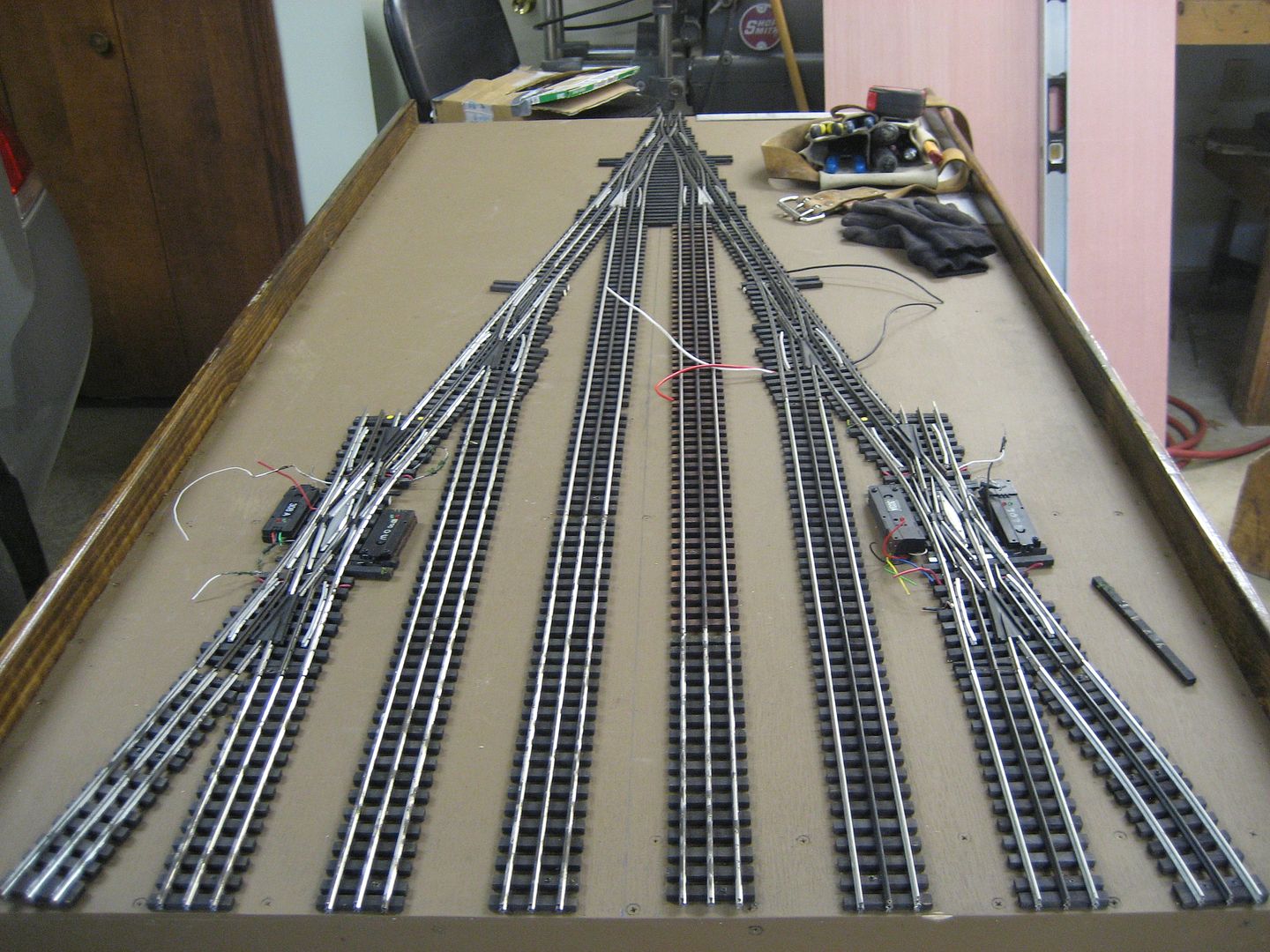

Yard lead, (4) track, couple of standard Ross switches, and a couple of double slips.

Another look with Ross 3 way switches.

Mike CT posted:Another look with Ross 3 way switches.

Mike,

Can i use that 3 way switch with Atlas? What degree is that switch?

In your drawing example, you are diverting right from the main, creating two new tracks. A 3 way will not accomplish this. A three way diverts left and right from a main.

Ron

Ron045 posted:

Ron,

I want mine to look like yours......you use 048 or 54? I want a right hand version of your left hand yard.

Those will require more space because of the abrupt turn. I don't have track planning s/w so I can't give you a quick answer. But I think I have some spare O-54 and will measure it for you. O-72 would probably work better.

Ron

Ret.Leo posted:Mike CT posted:Another look with Ross 3 way switches.

Mike,

Can i use that 3 way switch with Atlas? What degree is that switch?

The Ross three-way switches pictured are done with standard Ross switches, which I think are #5's. The Ross 204 three way is a combination of a couple of Ross #4 switches. Look closely and you can see the diverge difference. We (Fort Pitt High-railers) had the #5's as part of the remodel of this module.

I did not have O-54 but I had O-31 and O-72. So for reference, O-48 and O-54 will be somewhere in the middle.

It's a trade off of length vs width. O-72 requires less width but needs more length to straighten out. 54, 48 will need more width but will straighten out sooner.

The first two are O-31. The next two are O-72.

Attachments

Ron045 posted:I did not have O-54 but I had O-31 and O-72. So for reference, O-48 and O-54 will be somewhere in the middle.

It's a trade off of length vs width. O-72 requires less width but needs more length to straighten out. 54, 48 will need more width but will straighten out sooner.

The first two are O-31. The next two are O-72.

I'm going with the 072 switch.....one more question, what curve track do you have attached to the switch?? I really like how that looks.

Typically you match the switch/ curve. So an O-72 switch counters with an O-72 curve.

Ron045 posted:Typically you match the switch/ curve. So an O-72 switch counters with an O-72 curve.

Thanks Ron....i really appreciate your help

FWIW: It looks like there is enough of a straight length at the end of the curve so that there might be just a bit of an s curve? I am just wondering because a siding coming off a straight main run using a turnout like O72 as opposed to a number 4, 5 or 7 may require a short piece of straight. But the distance between the main and siding would increase. My sidings start toward the end of a curve on the main where I connected the curve to the straight part of an O72 switch. The curve then continues as far as I need and at the end of the straight track I install O72 curve(s) as needed for the other track. This of course may not work for your needs.

My opinion: For sidings, where you are trying to get your tracks to be parallel with each other, you want to avoid the O42, O54, O72, etc., and instead use a "numbered" switch, such as a #4, #5, #6.

The reason is that the "O" switches are designed to fit into a curve. This means that the whole length of the diverging track is curved. And that means that you when you add a curve in the opposite direction to get it back into parallel, you are creating an S-curve. It is a layout planning best practice to avoid S-curves as much as possible. In scale model railroading, this is for reasons of reliability in operations. In 3 rail, it is mostly for looks.

In the 'numbered' switches, the curve is concentrated between the switch points and the frog; the diverging track is straight, and exits the switch at an angle: it does not form an arc. This means that the wheels on your locos and cars have a few inches to straighten out before curving back the other direction. If you look closely at Ron045's photos you can see this. Look how the crossover between the tracks (in his first photo) is a straight line. He says he is using #4s. That is preferable to two back-to-back curves, which is what is shown in his later photos.

The curve in the #4 is about the same as an O72, so you should be able to get back to parallel by hooking an O72 curve section onto a #4 switch. If the tracks are closer together than you'd like, you can always add some more straight track before the reverse curve.

FWIW.

NICKAIX hit the nail square on the head that I was trying to describe.

A quarter or half straight before a two step ladder O72 would avoid the S curve. If the OP has 48 and 54 curves an O-72 S won't hurt him.

Thanks guys.....and thanks Ron for the pictures..you went above and beyond to help me.