Originally Posted by Serows1:

Originally Posted by Moonman:

Ross has curved switches that would let you put a siding along the inside of the run to the tunnel. Starting back in the curve will let you keep it tight and not eat up your scenery space inside the loop.

There's an 054 to 031 that you could straighten out without a lot of length using a transition track

Most of them need straights. I agree, more work than result placing them on a curve.

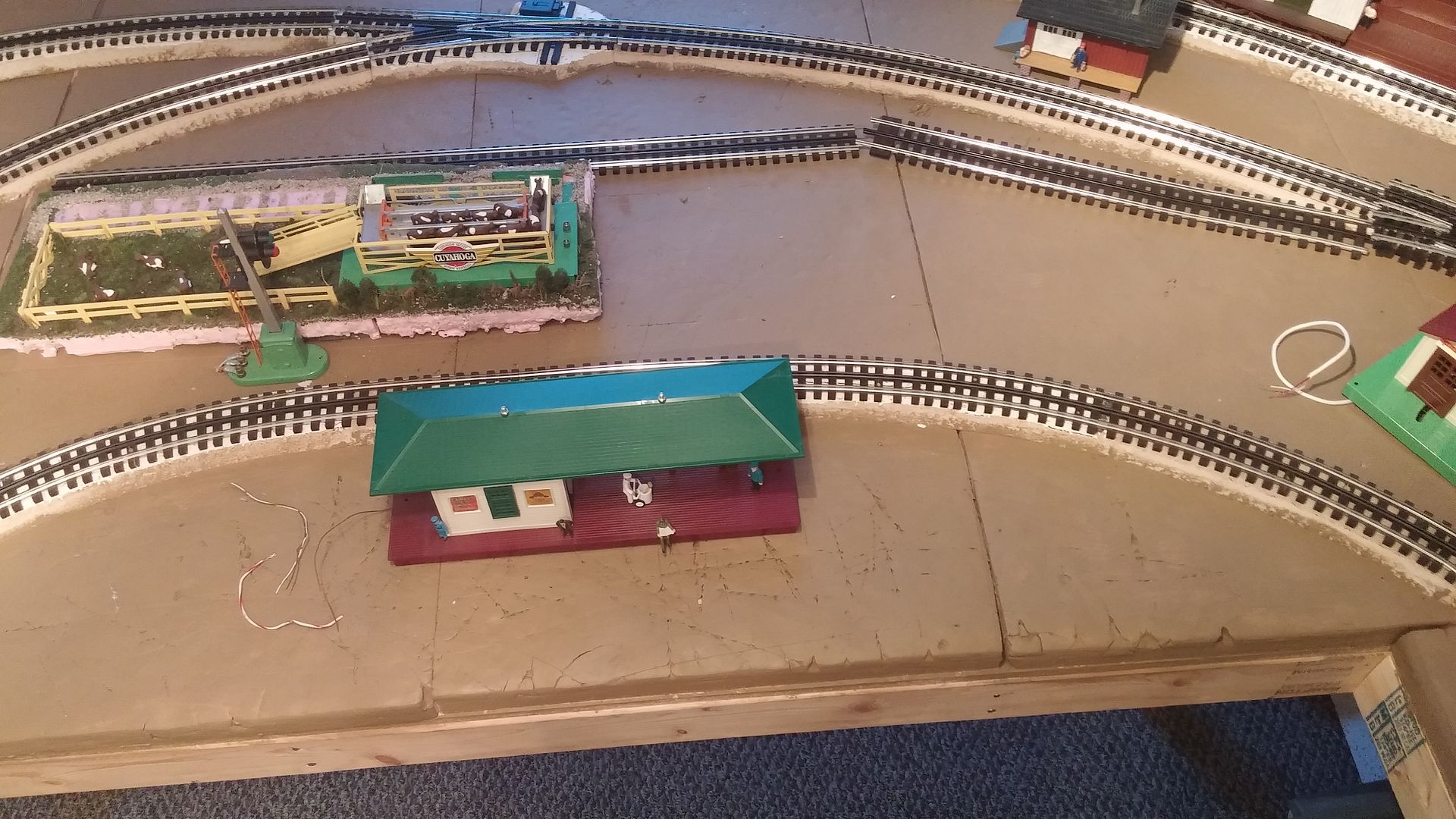

I hadn't thought of that, it might give me a small stub siding to locate an accessory, I'll have to take a look at the layout closer tonight.

I have the RRT software and used it partially on this one but I did most of the layout planning by laying the track on the available benchwork, I felt because I was using Gargraves flex track it would be easier to plan.

Plus, I'll take some updated pics tonight and post them so you can see what I've got going now, it's changed a little.

Paul

Would you use the add attachment feature for the new photos? It's allows them to be enlarged when viewed on the forum.

The bases of most accessories need either 6" or 10" between tracks or enough space for that footprint width. The log loader unloader needs 6". The older style coal loader with the dump bin on the other side is 10".

The culvert and barrel loader\unloaders are 6", but really long.

Spreading the cross-over near the tunnel a bit should let you fit the log loader in between with only minimal adjustment to the inner loop approach.

Anyway, most them need at least a 10" straight for an activation\operating track.

You can recreate your as-built track, even you if you have custom radius turns in RRT. Then you can plop your accessories in and see what it will take to fit them.