The inspiration picture is below and the current state of our model. Just about to start adding some color and start on second structure on the roof.

Thanks,

Mike

|

|

Replies sorted oldest to newest

Looking at the detail and intricacy of your model, I feel almost guilty here. The barn in the photo below (and the farmhouse) was made of foamcore with wood reinforcements at the corners, covered with printed paper: I went on-line and found free roofing and siding pictures, etc. In this case I used rusted/weathered metal roofing for the barn . . . It was easy and it looks as good as it could from three feet away - you can't tell its printed paper. You might consider this for the roof . . .

Evergreen, Plastruk, and JTT all sell while plastic (I think styrene in all cases) sheets embossed/molded with various patterns. I used some on the roof of the cathedral below: a very formal diamond roofing tile shape. they make them in a wide variety of roofing and siding patterns - it can be difficult to determine which is best for you over the internet. Best to got a a good LHS with a lot on hand to select them unless you know them well. I've seen various types of shingle patterns.

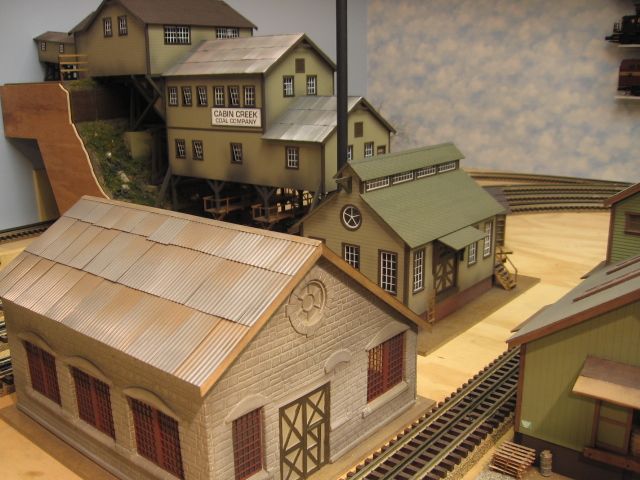

I used a different panel on the roofs of the two buildings in back in this picture. sorry it is a bit fuzzy. A type of corrogated roof again, but this is plastic and 3-D, not printed paper. I think this is Evergreen.

Finally, you could get small strips of roof or paper and cut indidivual shingles and glue them on starting from the bottom edge and working up as they do in the real world. I have seen this done although I have never done it, and it looks very good and it does not take as long as one would think. Just have to be careful not to spill the glue.

Mike,

Plastruct sells patterned sheets simulating shingles. If I were doing a wood or tin roof, I would use Evergreen board and batten on simulated metal roofing. All these products are made using styrene. When using the Plastruct material, I would use a backer of .040 styrene.

Your barn looks great.

Alan Graziano

![]() Wonderful project, Mike.

Wonderful project, Mike.![]()

Click on the underlined phrases to link. Builders-in-scale. You should be able to do corrugated metal roof, or a variety of shingles.

Builders in scale metal roof.

BTS also does paper press and stick shingles.

BTS press and stick shingles.

I constructed a 36" wooden building, very similar to your barn, as a replication of a former factory we had in town. I individually applied the siding after I constructed a complete post & beam frame from poplar I cut in my workshop. For the roof I used plastic pattern sheets. Since there is no real good way to join the seems of the plastic, I have three very distinct lines in my roof. For the amount of work I put in it, I am pretty disappointed. I probably will remove the roof, and have a printer print me a 36" long piece of paper with shingles on it, like Lee did, only longer. For the time & work that is evident on your barn, I would avoid plastic sheets, unless you get one that will entirely cover the area without middle seems.

I've used Plastruct shingle sheets, individual strip shingles, simulated tar paper, cork-based strip shingles, simulated tar paper, and Evergreen styrene standing seam "metal" roofing. All have their place. I don't believe most barns use standing seam roofing due to initial cost.

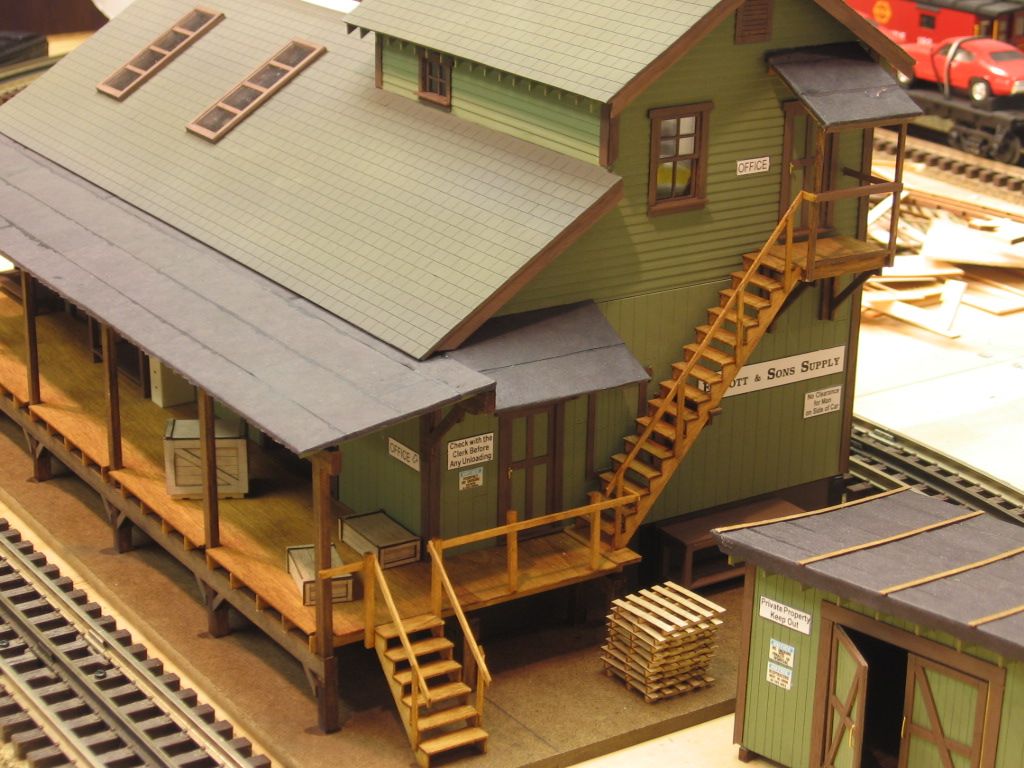

Bar Mills Gravely Building with their self adhesive, strip shingles painted weathered black and weathered with Dr. Brown's weathering powders.

Plastruct sheet shingles painted weathered black, individual shingles picked out with lighter shades with red and green, dusted with Dr. Brown's weathering powders.

Bar Mills Idaho Hotel with Evergreen Standing Seam roofing. Painted oxide red with dry brushing and weathering powders.

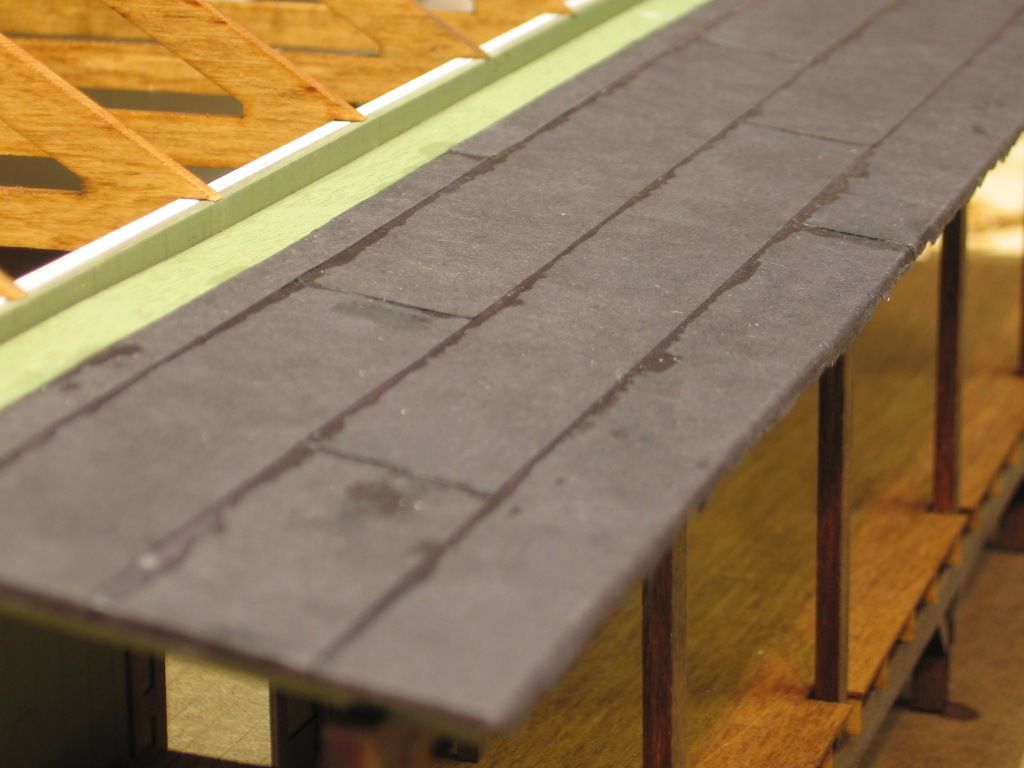

Scratch-built "Shingles" cut from 400 grit emery paper strips and contacted cemented to roof of Gloor Craft Coaling Tower

Sterling Tower by Model Tech, Inc. with their included cork-based, self adhesive shingle strips.

Bar Mills Saulena's Tavern with simulated, self-adhesive, tar paper strips again painted with weathered black and aged with powders.

In my opinion, every one of these methods makes a believable roof. It now depends on what you want the barn to look like.

Hi Mike,

Your barn looks fantastic so far.

We you be attending York in October ?

Alex

Tar paper on a BTS kit.

Wow, there is a lot of talent here. gorgeous buildings.

A Korber kit, Quincy Mining, with plastic corrugated roofing. I pre-painted the rust on the pieces before attaching them to the roof panels. Front left building.

Marcos Brothers roofers applying roll roofing on my Enginehouse [to hide the slick shiny look--1" masking tape painted flat black].

I am currently putting shingles on a roof using weathered gray shingles from Bar Mills Model Works. See: http://www.barmillsmodels.com/...rt&Itemid=999123

Some really nice roofs on some really nice buildings....I have used many of these

methods cited above to get variety, but all are covered above, so nothing I can

add. Your photo of the prototype APPEARS TO ME to have individual wooden "shakes".

a laborious task, but one that allows dyeing a batch, and then another batch a few

shades off to get that photo's effect. I might try 1/8 to 1/4 inch thin stripwood,

cutting each shingle off with pinking shears, which come with round and saw-

toothed blades, then rough them up on heavy sandpaper. Since they would overlap

you can go through one strip fast, switching shears, with one cut per shingle.

Tissue paper roof is part of some BTS kits. These ones would almost look like a sheet metal roof. The raised edge, along the hip roof seams, is a piece of brass wire.

This BTS kit was my first attempt with paper shingles. Best to do a pre-paint of the press and stick shingles, while still on the card-stock, before shingle application. The paper shingles will shrink as the acrylic paint dries. I had some problems on the long roof due to shingle shrinkage, (paint applied after the shingles were installed)![]() .

.

I have used aluminum foil to make corrugated metal roofing. Either buy a sheet of styrene corrugated or find a large piece from a kit and use it as the pattern. I cut the foil into strips that are as wide as the length I want the roofing pieces to be and then lay the foil strips on the styrene pattern and emboss the corrugations into it with a stiff brush or even your fingers. If you reach the end of the pattern before you get to the end of the foil, advance the foil leaving a few rows to lock into the pattern so everything matches. When the strip is done, cut it into sections to make the individual pieces of roofing material. Usual prototype sizes are 2 feet wide and 8, 10, or 12 feet long.

It's a bit tedious, but with practice you can make quite a bit of roofing in little time.

Have also used 400 to 600 grit wet/dry sandpaper cut into scale 3' wide strips to use as rolled roofing. Regular off white masking tape can be used for tar paper roofs too. I'd use additional adhesive with the tape though as the masking tape will start to let go after awhile, especially if painted with water based acrylic paints. lol

Access to this requires an OGR Forum Supporting Membership