Hi Everyone,

Quick question, I have been debating adding an additional 180-watt Lionel Powerhouse to my layout.

My current power setup is as follows:

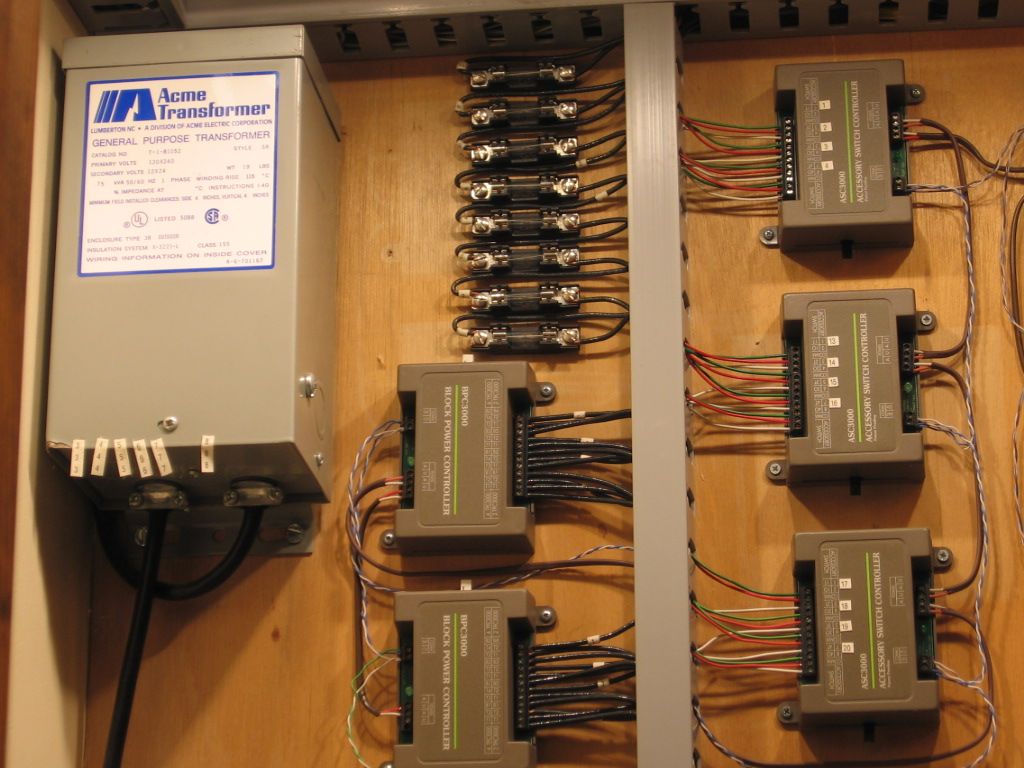

Lionel 180-Watt Powerhouse

Lionel Legacy Powermaster

Lionel Legacy Base and Legacy Remote

Naturally, all of the wiring is pretty straightforward (I do not have blocks and/or power districts on my layout):

-Powerhouse to Legacy Powermaster via molex plug (Powermaster has ID: TR 2 in my Legacy system)

-Legacy Base Common to Powermaster Common (U to U)

-Hot and Common wires (A and U respectively) to my track from Powermaster

If I were to add an additional 180-watt Powerhouse, how exactly would I accomplish the inclusion of the additional brick?

Would I need to purchase an additional Legacy Powermaster, create the same aforementioned wiring set-up and then "phase" the Powermasters by connecting common to common on each? Or is there a way to simply add the 180-watt brick using only one Legacy Powermaster?

I appreciate the input.

Best,

Michael