From the Atlas website. 200 Snap relay would be wired parallel with the switch motor.

Requires a common, Through and Out from the #57 or #56 push buttons. As noted it allows several functions related to enhanced switch operation. Note that most of the detail explanation is related to HO switching.

A double-pole, double-throw relay with actuating mechanism driven by a momentary-power, twin coil solenoid. (A solenoid is a cylindrical coil of insulated wire in which an iron core is made to move back and forth by a flow of electric current.) With just a few simple connections, this small device, which may be mounted anywhere, can:

- Power the frogs on Atlas' Mark 3 & Code 83 #6 turnouts

- Control trackside signal lamps to show turnout point positions

- Operate control panel lamps to show settings of remotely located turnouts (switches)

- Provide selective track siding control. Sidings are powered only when points are aligned for siding. Siding remains dead when points are set for the mainline.

- Control X-sections automatically. This very useful track arrangement is thoroughly discussed in Atlas' Complete Wiring Book.

#57 lighted switch control is a relatively new push button switch control that has lighted through and out indications. Not required, you can use the switch button provided with the Atlas track turnout switches. I believe it is listed as a #56 switch control, through and out. Noted problem with the #56 is stuck buttons that causes the switch motor burn outs. I don't know that using the #57 lighted switch control would solve the burn-out problem, contact Atlas on this.

6924 relay board. has a built in time-out feature that inhibits switch motor burnout. It can be used with your existing #56 push buttons. Push and hold the button too long the relay board will time-out preventing switch motor burn out. The #200 snap relay would not time-out. Good chance that a stuck #56 button will cause both the switch motor and the #200 snap relay to burn-out at the same time. The 6924 board will also address the dead spot problems of the switches and there are other functions.

There is a lot of information on this Atlas page about the 6924 relay board.

(1.) One of the problems with the Atlas spring loaded non-derail switches is they don't seem to work well. If you enter a switch the wrong way the spring loaded points are to give enough that the train will roll though the switch without de-railing. First function of the 6924 Non-derail board automatic switching when you enter a switch from either direction.

Non-derail wiring diagram.

(2.) Established automatic non-derail allows for power routing of the dead rails in the center of the switch. Doing this should enhance engine movement through the switch assuring power. Power routing.

Power routing.

(3.) You can also add the 6931 dwarf lights if you wish using the 6924 relay board. I preferred to use the small PC board provided with the dwarf lights.

6931 Dwarf lights added.

(4.) Using the #57 switch with the 6924 relay board. Note that the red/green indicators on (#57) are powered through one set of contacts on the 6924 board. There are (2) sets of NC/C/NO contacts available on this board.

#57 button/6924 relay board.

Question #1: Do I need both components (#57 & #200) or do I use one without the other? If you are using the #57 switch, the #200 relay is used to power the LED/red/green on the #57 switch. This diagram.

The #200 relay would also allow for electrical enhancement of the gap/dead spot in the switch, or the addition of some on-layout switch indication lights. There are (2) sets of normally open (NO), common(C), normally closed(NC) contacts.

Question #2: What is the purpose/function of the #200 snap relay? (What does it do that enhances the operation of the turnout?) Note the power routing diagram, provided via link above. The #200 relay would provide the ability to do power routing, which eliminates the dead spots in the center of the switch. It also powers the red and green LED's on the #57 switch.

Question #3: What is the function of an Atlas Non Derailing Circuit Board (#6924)? Noted above. Primary function is to inhibit switch motor burnout. There are other functions available.

Question #4: Do I need an Atlas Non Derailing Circuit Board if I use a snap relay? No, but the snap relay would not solve the problem of switch motor burn out.

Hopefully that get you started with these interesting devices.

Best wishes Mike.

Best wishes Mike.

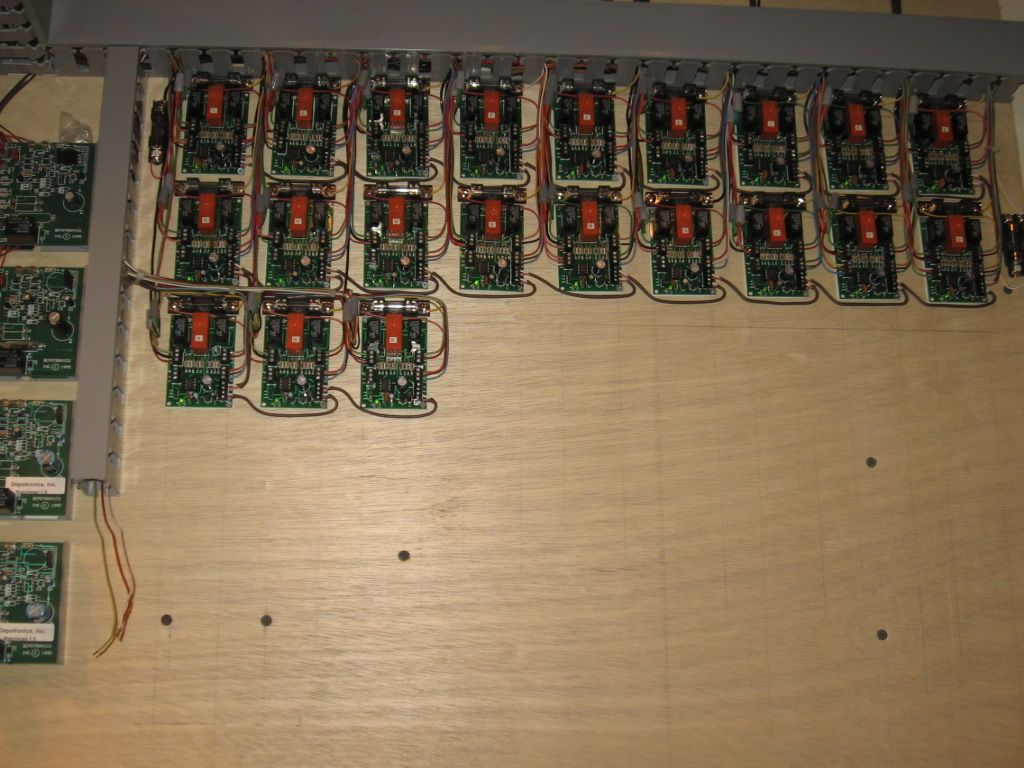

A couple of my 6924 relay boards installed.

I haven't burn a switch motor since I installed the 6924 boards.