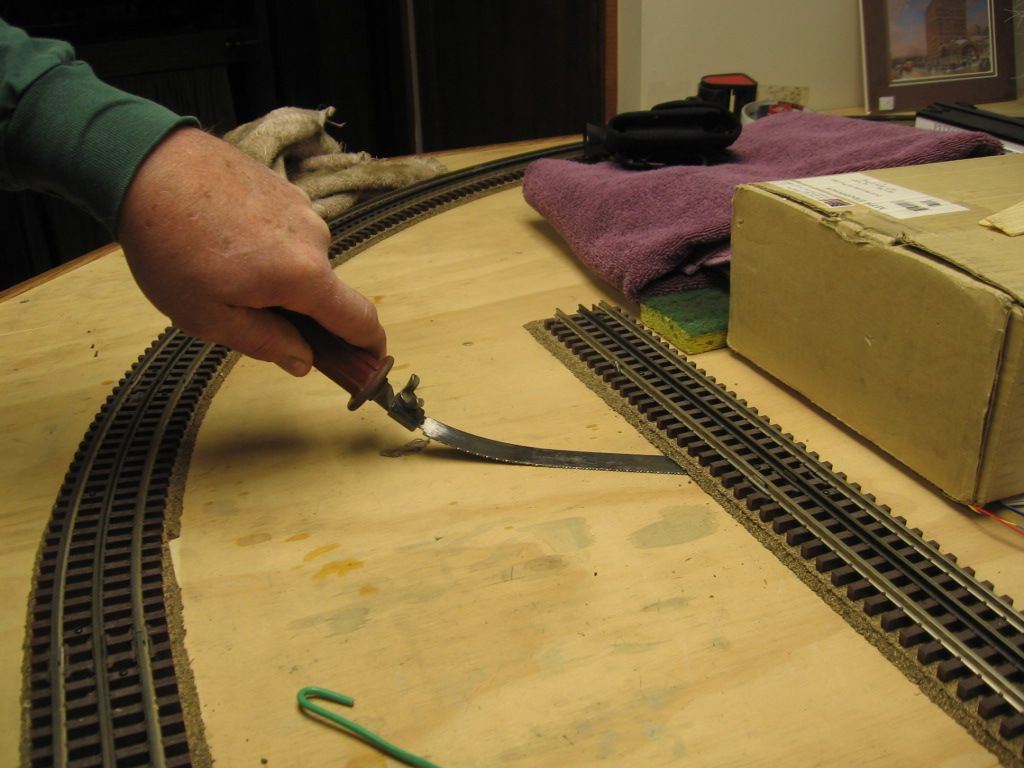

I need suggestions on cutting a hole in the peak of the roof of a train station. I think it is a Lionel train station. The material is either a hard plastic of a resin material. I want to make a thin slot on the very peak of the roof to mount a Miller Engineering Amtrak sign. I want the slot to be just big enough in thickness & length to just put the connector of the sign in it & let the sign sit right on top of the peak of the roof. Any suggestions would be greatly appreciated.

Ken M