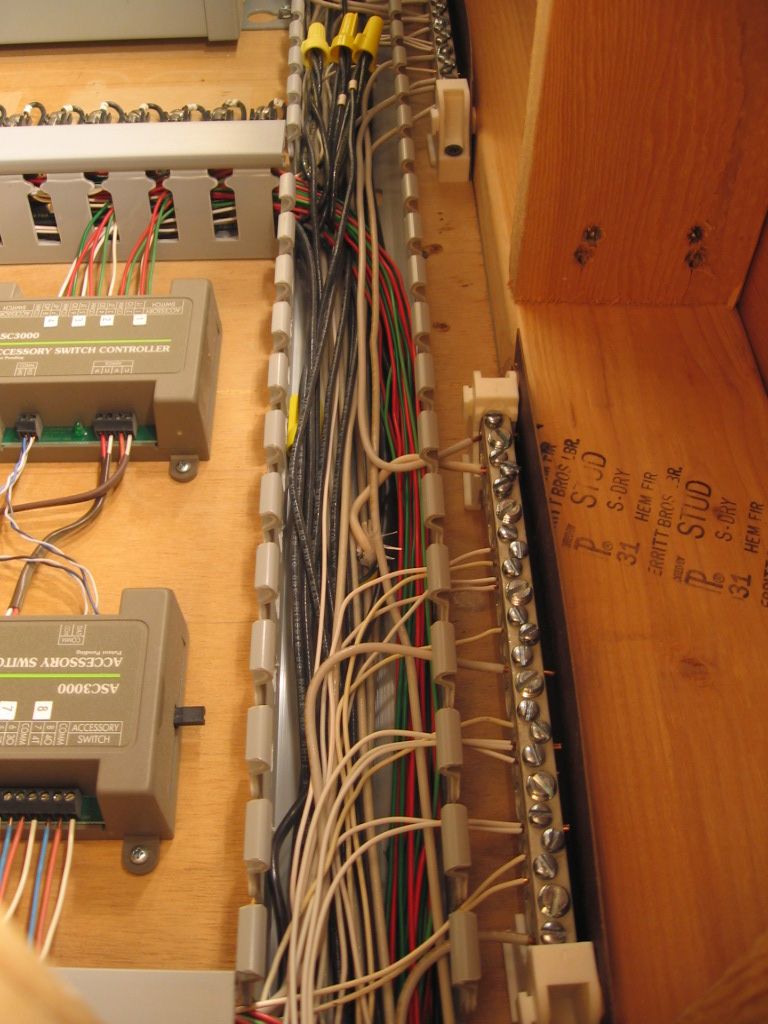

In the excellent thread "My new Train Room a work in progress", Charlie (from Michigan) posted a photo of a barrier strip leading to some drops he's been soldering:

His work is neat and impeccable, but I have a basic question: What is the purpose/advantage of using the barrier strips? Is it just for the sake of neatness/maintainability?

I'm probably not letting go of the knowledge developed as a teenager when I learned all this stuff, but I would think that the barrier strip would represent an additional point of resistance for the current running from the transformer to the track. Wouldn't a wire running directly from the transformer post to a soldered track lead result in more juice arriving to the track?

When I did my last layouts, I ran a wire directly from the transformer post, guided it under the table, and soldered multiple drops from the center rail directly to that wire. I did more or less the same thing for the ground and ran several ground wires from phased transformers all around the underside of the layout. I soldered the outside rails and other things needing a ground, directly to the ground wire for the return trip to the ZWs.

Is the purpose of the barrier strip simply to increase tidiness/flexibility or -- as so often happens -- am I unaware of some fundamental point?

Thanks in advance for your help.

Steven J. Serenska