Does anyone know why a dz-1000 will work some of the time? I have 12 new machines , 4 of them are giving me problems, 2 will snap nicely and then won't move, or only move half way , try them again and they work. the other 2 won't move the switch at all, dismount them from the switch and they snap fine. I'm running 14 volts to them off the 14 volt acc terminal of a z-4000

Any ideas?

Thanks Fuzzie

Replies sorted oldest to newest

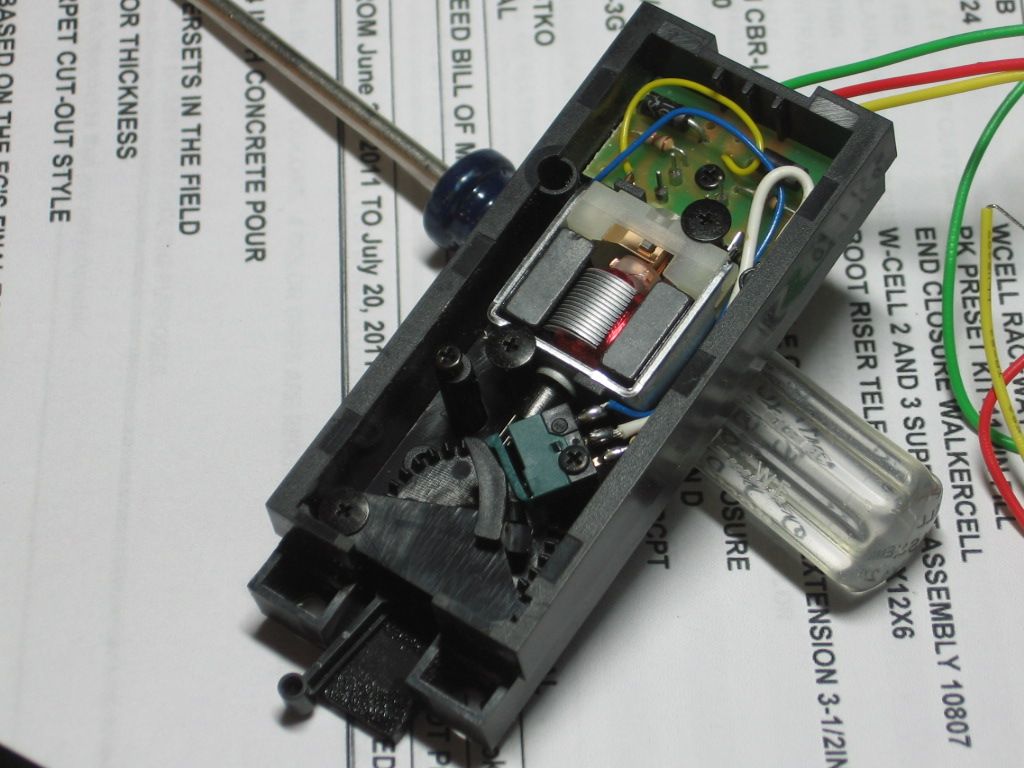

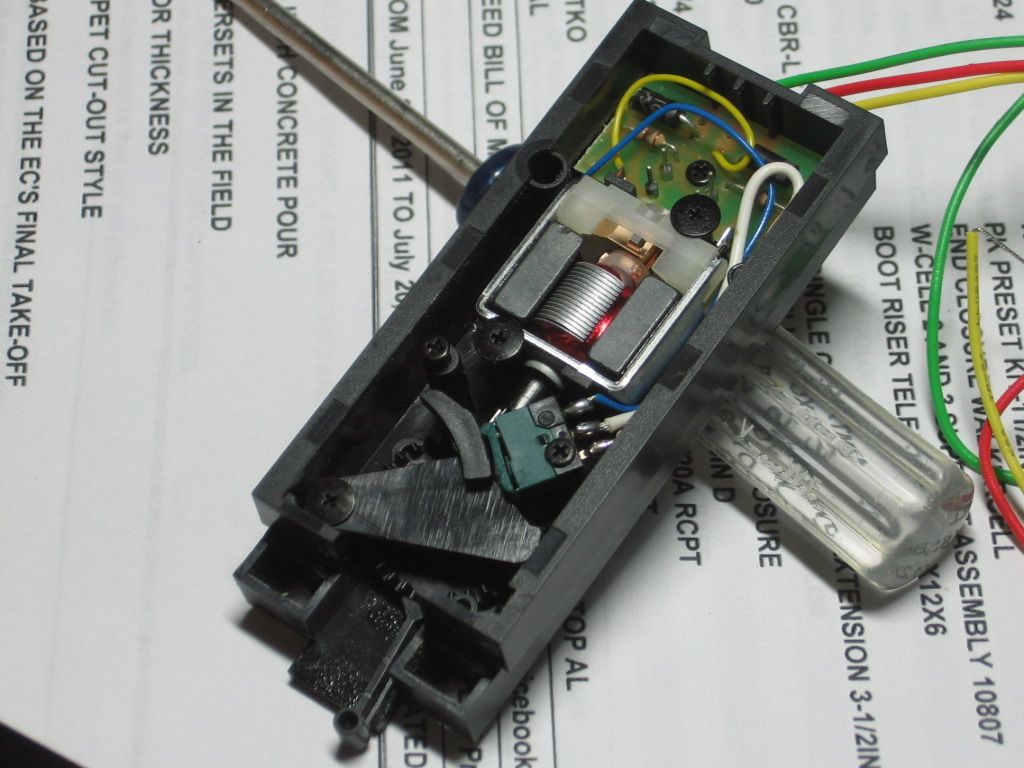

Most likely some mechanical binding that SHOULD ![]() loosen with use (but don't hold your breath). Second, might be the turnout points are tight and binding or jamming too tightly against one stock rail or other. Third, A more common problem is that the internal cam disk lug does not rotate completely to hit the microswitch lever that cuts off the motor power and reverses its connections for the reverse movement when called for. No adjustment inside for switch that I found.

loosen with use (but don't hold your breath). Second, might be the turnout points are tight and binding or jamming too tightly against one stock rail or other. Third, A more common problem is that the internal cam disk lug does not rotate completely to hit the microswitch lever that cuts off the motor power and reverses its connections for the reverse movement when called for. No adjustment inside for switch that I found.

ZStuff supposedly reengineered the cam for reliability, and they swapped the old for new one (plus $9 each). I honestly can't say they seem to work any more reliably (but thats just me, your mileage may vary)

Best bet is call Z-Stuff for replacement(s).

Fuzzie,

I also have 12 of those on RCS turnouts, and they can be a PITA. As you found out, sometimes they work fine, other times they do not, and the malfunction is not always the same. Either they do not advance fully, or they do advanced fully but bounce back. I video-taped one and played back in slow motion, and you can clearly see the bounce back; sometimes half-way back.

Most of the machines never move fully into position, but the points are thrown all the way, so I don't worry about it (but have had occasional problems). They do seem to get better with age, though [just as the rest of us ![]() ]

]

I tried different voltages and ended up running the DZ1000's, and the Atlas solenoid machines, with 18VAC, as this provided the best results. No issues with the 46 Atlas machines on my layout.

It is a shame because the DZ1000 machines are well designed, but perhaps too complex.

Good luck,

The small green switch limits burn-out???,

The small green switch limits burn-out???, I've added oil from the top, via the manual throw pin which seems to help, some.

A year or so ago, I worked out a electrical design using 2 microswitches configured such that a complete throw was gauranteed as long as there was power to motor ie hold button down until throw completes, no bounchback. That is, if motor bounched back, the circuit reclosed, reactivating the motor to complete the throw then shut off and ready for running the opposite way. Wired it up and proved it worked on bench. Problem is that you can't get two switches inside present case, and of course the biggie is tooling for new case and internal parts.

Sent design to ZStuff gratis, with a free to use no charge waiver, but owner never responded back, yah or nah (legal issue?) ![]()

And to borrow and paraphrase a line from Fiddler On The Roof. "If I were a rich man...I'd do ado ado this design MYSELF, If I were a rich man........"

I rewired the dz-1000's to a variable voltage output, gave it 20 volts and they ALL work GREAT now.Maybe these things need to run at a higher voltage ?

Thanks everyone for the input.

Fuzzie

Fizzie,

Wow that 20V seems high. Surprised that the ZStuff levers don't bounce back after hitting the end stops. But whatever works.

I found out that backing off the switch machine mounting screws just a tiny bit so that the machine could "float" would sometimes clear up the binding. Also make sure the switches are mounted flat against the table. I had one that bounced occasionally and in messing with it I realized that I had too much torque on the switch mounting screws. They can even be backed off, which sometimes helps. And in one case, when I mounted the machine on the opposite side of the switch, it would stop acting up. Otherwise, no problems with 16 of them.