Per request, here’s how I handle the DZ 1000 switch motors. First, I mount the controllers on my control panel, which has a sketch of the layout. I mount the controllers over the switch locations. I insist that the illuminated LED be over the branch for which the switch is set, and that if I want the train to take the other route, the button to press is over that route; in other words, adjacent to the non-illuminated LED. I make no exceptions to this rule. If there is a location where one controller controls 2 switches, I mount it so the lights are in the most logical position to indicate route.

1. If, after wiring a switch, I find that the button to press is adjacent to an illuminated LED, I reverse the controller LEDs and mount the controller accordingly.

2. If, after wiring the switch, I find that the buttons move the switch in the wrong direction, I switch to the R and L connections on the switch motor. Then apply 1 above

Now for when I want to have a single controller throw two switches, such as in a crossover. This can get complicated.

3. If I have a simple crossover, two left-handed or two right-handed switches with the curved sections connected to each other, and the switch motors in the same position on each switch, simply connect the two R terminals together and the 2 L terminals from the switch motors and run to the controller. Then see above.

4, If I have two lines intersecting at a cross track, and install a track permitting the train to go from one line to the other, if I use a right-handed and a left-handed switch, with their curved sections connected, then on one of the switches I must reverse the location of the switch motor, which I can do in one of two ways. I can either rotate the switch motor 180° on the same side of the switch, or relocate it to the other side of the switch. Then simply connect the two R terminals together and the 2 L terminals from the switch motors and run to the controller. Then see above.

5. In two locations I have a crossover on a curve, so that the straight side of one switch is connected to the curve of the other. In one of these, have used a double-curved switch for the outside track; in the other, the parallel main lines split. In both, I am wanting the controller to show green when one (and only one) of the switches is set for the train to take the curved portion. Step 1 is to mount the switch motors—see 4. above—so that when both Ls are energized both switches go in the one desired direction and when both Rs are energized they go in the other. The apply 1 & 2 above.

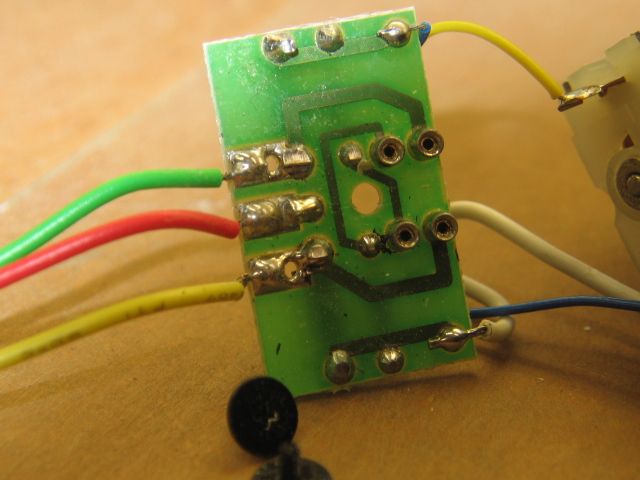

The switch motors are ingeniously designed, with a small motor, a microswitch, and 2 diodes to control the direction of current flow through the motor. LEDs are polarity sensitive. Thus, sometimes it will take a bit of experimenting to get things right.

Do not use the DZ controllers to control any other brand of switch. They are designed for the tiny draw of the DZ1000 switch motors, and can’t handle the heavy current required by solenoid-type switch motors.

![]()