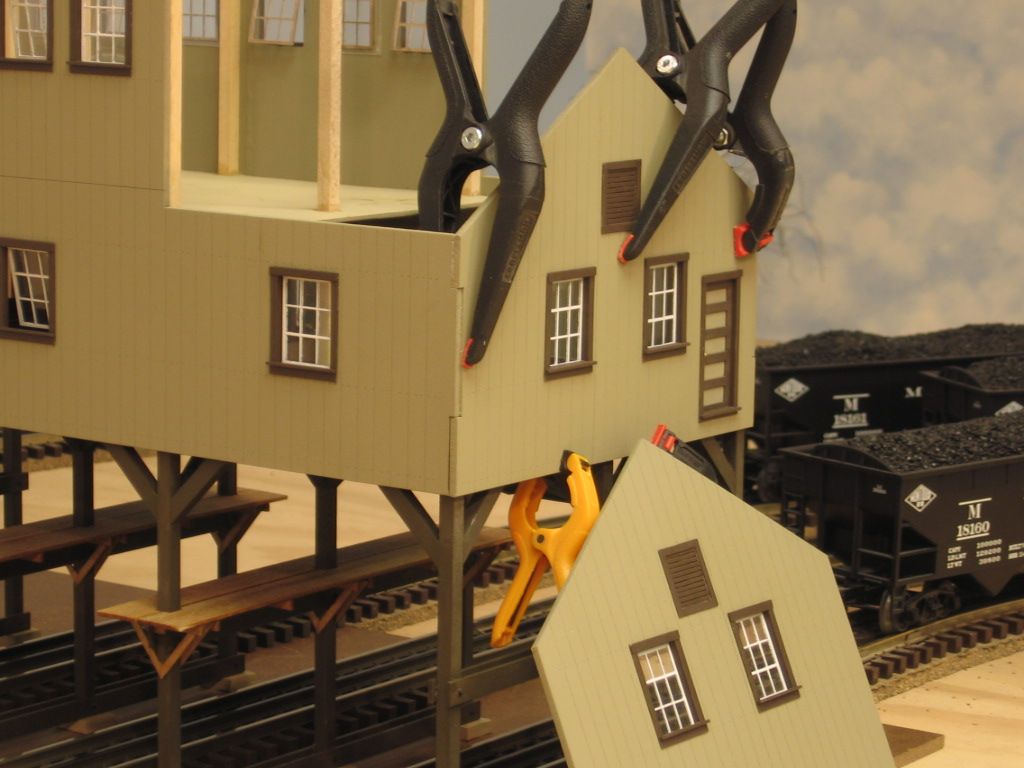

As you likely know, you can fall down a long rabbit hole when it comes to discussing various glues and their applications - so I'll try to avoid stepping into the hole directly... "ordinary" Gorilla glue does require clamping and any excess you see coming out from a joint will dry with a hard foam appearance. It wants to expand as it cures - one reason for clamping. I've used it for some home repair projects and its tough stuff, but not the easiest to use. Because its moisture catalyzed, I've had a couple of bottles turn to bricks from the moisture in the air (even with the cap on). Gorilla makes a clear glue version of this that I've used - it has the big advantage that it doesn't expand, though the package still recommends clamping. I tend to buy the smallest unit I can find just to avoid having to throw away a large bottle turned to a brick, but so far the small bottle of the clear glue is still viable.

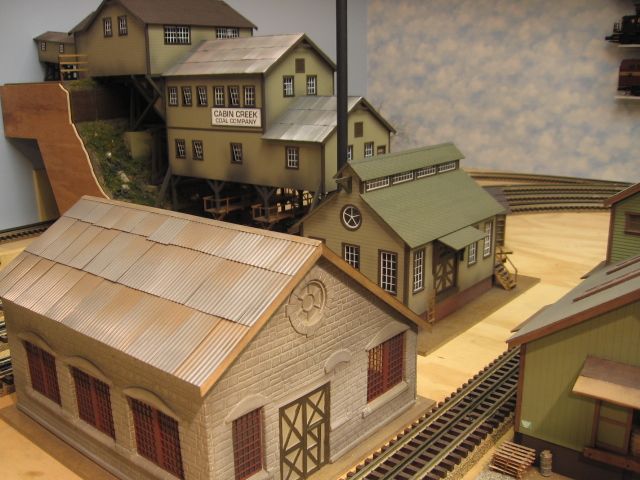

For woodworking a lot of us use titebond 2 or 3 - I use 3 because it has a longer working time. As with most glues it recommends clamping, but I would think for things around the layout where strength of the glue joint isn't very important, you could use it without clamping as long as the pieces stay together (gravity...). there always the fall back to the 'household' glues like E6000, which don't need clamping, but they don't set up very fast (I think of it as a modern day version of the old Testor's (?) model glue a lot of us used for gluing plastic airplanes/cars/etc. back in the day.

CA glue (cyanoacrylate and its cousins, aka superglue) has the advantage that it is quick setting, so clamping may just be a matter of holding the pieces together for a short period of time. My experience is that there are some materials it doesn't seem to glue very well, including some plastics. but it does a great job on fingers... Again I try to buy the smallest unit I can since the shelf life after opening tends to be pretty sort.