I often use two sets of curved hemostats for bench splices, loop tips on heavier wire. Just line them up the same and lay them down. There is always something around to set on them if needed.

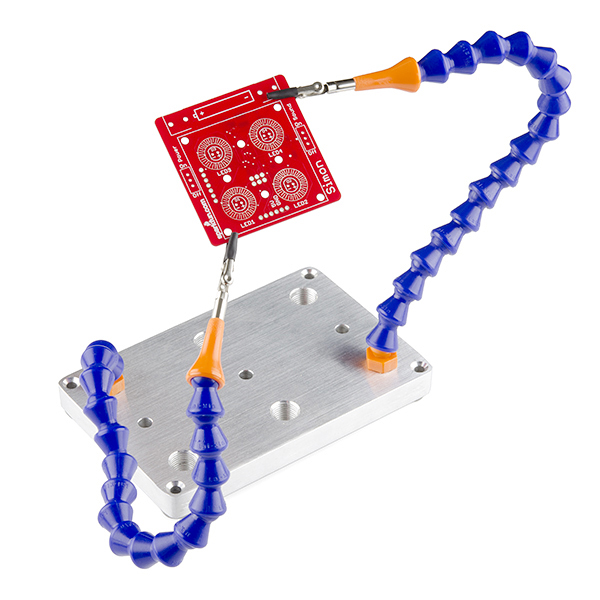

The blue and orange holder is machining coolant delivery tubes& nozzle with a gator clip stuck in it. "Government work"  There are more lockable versions of this multi-link spherical socket idea in the machinists world too (expensive

There are more lockable versions of this multi-link spherical socket idea in the machinists world too (expensive  )

)

The cheap dual-C articulation clamp type is pretty lame most of the time, but I often just use cheapies too. But sometimes I also use the better hardware of my heavier (dial) gauging bases; forged, magnetic, or hollow square bases with suction cup for glass work (a compass point for glass cutting "too"

Old machinist toolboxes at estate/ yardsales and inherited junk boxes has yeilded some good old knurled knob stand off hardware carried in the pocket for a day for just a few coins mostly. I could do a couple huge S-es if needed. Brass or steel rod from a hobby shop or hardware store works for rod on any non gauging uses. The sizes and types of good rod clamps vary, but they are out there.

If I have them, stainless clips (from the electric or boat shop) is what I've used once I crush the cheap ones.(solder won't stick to most stainless. So you can also heat sink wire or touch with them with a soldering irons tip without them sticking)

Mounting points and cast ought to draw your attention to light weight  .

.

Mount it in a vice, maybe on a 2x4 or to a wider board/plate. If you have decent rods and hardware you could connect 2,3,4 or more bases together and work your way up with more rods. At work we would mount the small bases in small ball and socket base/ plastic jaw "hobby" vices with those vices on about 10" squares of wood covered in light anti static cloth which further helps keep from sudden, and then uncontrollable sliding on most benches.