Mine has been in place for 35 years just screwed in place. On the mainline there is cork roadbed. The only issue I’ve had is in a couple of spots is where I assume the butt joints are in the homesote. I see cracks running across my ballast and ground cover in spots. I’m guessing from contraction and expansion right at the joint. Maybe should have used flexible black caulk just on the joint ends. Not even sure that would have helped.

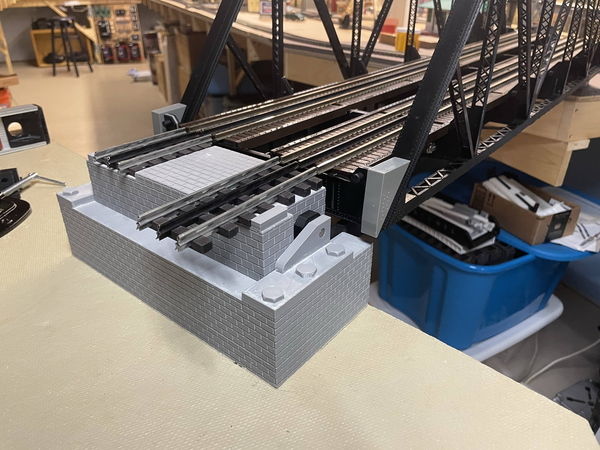

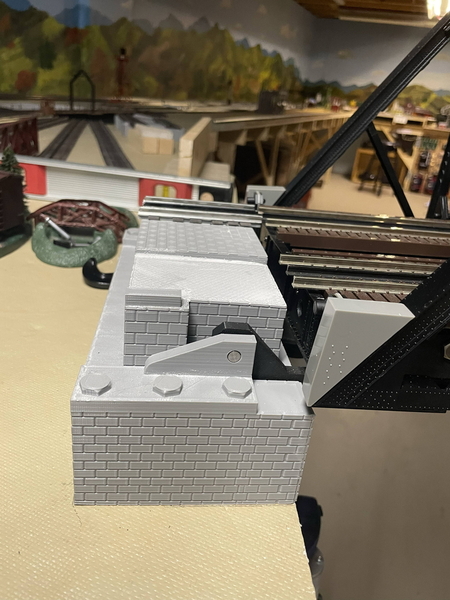

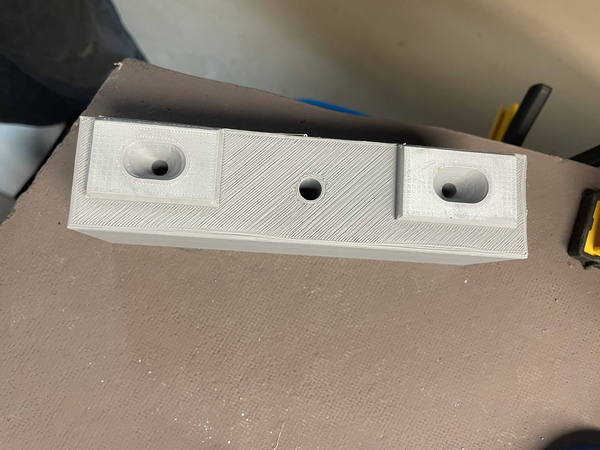

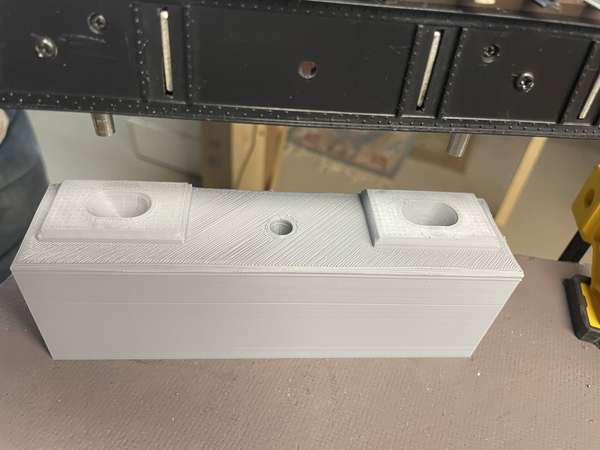

Homesote can be cut with a utility knife. One benefit of not gluing it down. If you build a kit that features a lot of scenic details around it for an area that has homesote over plywood. You can build it like a diorama on 1/2 plywood at the workbench. Then excavate the homesote and drop it in place. Then just scenic around it to blend it in.