The increasing popularity of covered hoppers in the 1950s set the stage for their wider use in the 1960s. With advances in car construction, improved loading and unloading facilities, the advent of 100 ton roller bearing trucks and an important legal case the covered hopper would become one of the most common car types on America's railways by the end of the 60s and they remain so to this day.

While the growth in size and weight capacity of freight cars followed a natural technical progression the use of the covered hopper car was slowed by overly restrictive government regulation of railroad rates in the early 1960's. The Southern provided a great service to farmers and consumers by going to court against the Federal Government in order to be allowed to offer lower rates to customers shipping grain in 100 ton covered hoppers and doing so in multiple car blocks. After several years of legal struggle the Southern prevailed and railroads and grain shippers began reaping the benefits of larger and more efficient specialized cars in grain service. The demand for modern cars lead railroads to buy high capacity covered hoppers in blocks of 100 or more. Soon several car builders were turning out thousands of 100 ton covered hoppers every year to efficiently haul grain and other commodities.

One of the earliest designs for a large capacity covered hopper for grain service came from American Car and Foundry. Their cylindrical hopper design from the early 60s held 3975 cubic feet and was available in steel or aluminum construction with three or six outlets.

Atlas brought their model of the ACF cylindrical hopper to market upon their return to the O scale in the late 1990s. Both the three and six outlet versions continue to appear in the Atlas product line every few years. Recent versions have trucks featuring rotating bearing caps.

Lionel responded with their own version of the 3 bay ACF cylindrical hopper. It is very similar in level of detail to the Atlas models of the same prototype.

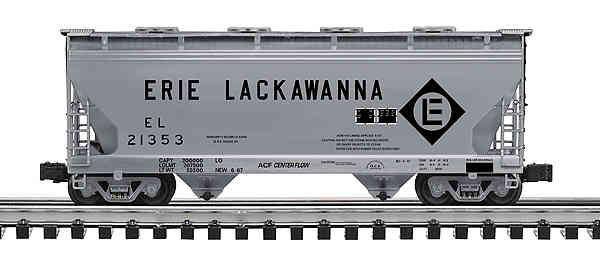

ACF responded to competition in the covered hopper market in the mid 1960s with their Center Flow hopper line. Center Flow hoppers feature outlets centered under the car with a semi-cylindrical car body and offered buyers a choice of round loading hatches or a nearly full length center trough. Car lengths varied depending on the commodity and the volume needed. The most commonly built and modeled cars in the ACF Centerflow line are two bay hoppers holding 2970 or 3200 cubic feet for cement, sand or clay, three bay hoppers holding 4650 cubic feet for grain service and four bay 5250 cubic foot cars for light weight grains or plastic pellets.

The earliest ACF Center Flow hopper model available in 3 rail came from Lionel. It has a detail level typical of models tooled in the 1980s and weighs a light 12 ounces.

MTH introduced their 2 bay ACF Centerflow hopper in the 2000 Volume 3 catalog. It has since received improved trucks and end details.

K-line produced aluminum 2 bay Centerflow hopper models as their K6242.

Lionel makes a short 3 bay ACF hopper. It has a 1990s level of detail but is the only model representing 3560 cubic foot cars for medium density products like salt and sugar that are heavier than grain but lighter than sand or cement.

ACF's most popular covered hopper was the 4650 cubic foot Centerflow. They were ideal for most types of grain. We have two different models to chose from in O scale.

MTH introduced their model of the ACF 4650 in the 2000 Volume 3 catalog. Recent cars have improved trucks and end details.

Lionel's Aluminum model of the ACF 4650 debuted in 2006. It features the longitudinal rib of early production Centerflow hoppers.

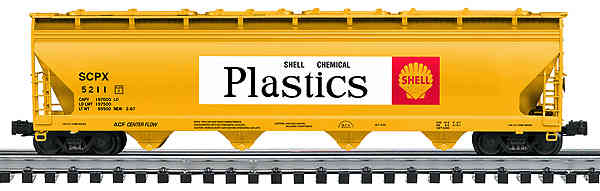

A longer 5250 cubic foot version of the ACF Centerflow hopper with four bays is used for plastic pellets or light weight grains.

K-Line made the K6244 aluminum model of the four bay ACF hopper that continued in production under the K-Line by Lionel banner.

Lionel's own Aluminum four bay ACF was introduced in 2003.

Weaver's plastic model of the four bay ACF Centerflow hopper has the longitudinal rib characteristic of early production cars. With plastic trucks they weigh 12 ounces, very light for a large car. More recent versions feature diecast trucks. Factory weathering is an extra cost option.

Pullman-Standard met the challenge of ACF with their PS-2 4427CD hopper. The 4427 built on the success of the 70 ton PS-2 design and added several desirable features. In addition to 100 ton weight capacity and a 4427 cubic foot volume Pullman was able to simplify unloading by reducing the number of outlet gates to three placed in the middle of the car for “Center Discharge”. The original configuration of the PS-2 4427CD featured low side sheets.

Atlas came out with a highly detailed model of this very popular mid 1960s car in 2001. From the second production run onward they have been equipped with trucks featuring rotating bearing caps.

Lionel followed in 2002 with a low sided PS-2 4427CD very similar to the Atlas model.

MTH came out with a model of the PS-2 grain hopper in 2001. MTH chose to model the later high sided version with 13 side ribs. It has since received upgraded trucks, couplers and details.

Weaver offered a model of the 4740 cubic foot version of the PS-2CD hopper with 16 side ribs. The Weaver PS 4740 tooling lives on in the Lionel LionScale product line.

Atlas makes a moderately detailed and moderately priced model of the later PS-4750 cubic boot covered hopper in the Trainman line. Built in the 1970s and 80s this version of Pullman's covered hopper has 18 side ribs.

MTH brought cylindrical hoppers to market in the late 1990s. The MTH 1997 Volume II catalog contained a model of the 4 bay 100 ton covered hoppers built in Canada by several builders and seen across North America.

MTH followed up with a shorter 3 bay cylindrical hopper for higher density commodities in their 1998 Volume III catalog. Both MTH cylindrical hoppers have received upgrades to their trucks, couplers and details since their introduction.

MTH first offered their model of the 100 ton General American Airslide 2000 Volume 3 catalog. Airslide hoppers have a special fabric lining that allows compressed air to fluidize granular or powdered materials like sugar or flower for easy unloading.

Today's railroads allow the use of 286,000 pound gross rail load freight cars that, for most commodities, allow them to handle 110 tons of cargo in each and every car. The 110 ton covered hoppers built by Trinity Industries are the Kings of contemporary grain service and are commonly seen in solid 100+ car unit trains shuttling grain between inland elevators and coastal export terminals. The Atlas models of the 110 ton Trinity cars are the Kings of O Scale modern covered hopper models in both side and detail.

As always, your comments or corrections are most welcome. And let's see photos of your 100 ton covered hopper cars.

Information on other types of O scale freight cars can be found at the link below.

https://ogrforum.com/t...le-freight-car-guide