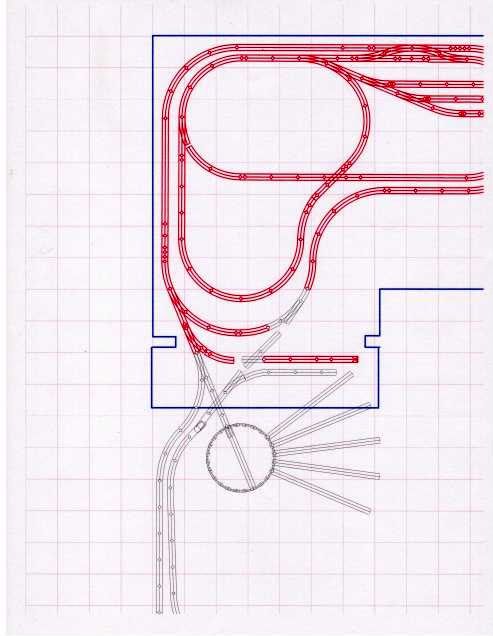

I’m in the planning stages for a new layout. I plan to build a double loop with O-54 curves (The layout is only 12x8 if it matters) on the outside and want the inside loop to remain parallel (same distance, center rail to center rail on the curves), attached with crossovers in both directions.

I’m debating between 3 track systems: Atlas O, Gargraves & Ross, or some combination utilizing Ross switches.

My question, simply put is what combination do you all recommend to achieve this? Using the demo of Atlas’ track software, I found I could use their O-45 curves on the inside and it lines up using their O-54 switches. I want to explore other track options as well and be able to maintain a parallel track all the way around my layout. Thing is, I only want manual switches and Atlas’ switch prices are out of my budget. I like how the Gargraves manual switches are attractively priced, but may be willing to pay for Ross as well.

Thanks in advance!