What is the best way to glue right angel plastic models?

Replies sorted oldest to newest

Micro Mark sells right angle clamps that allow gluing, and they have various accessories to enable a easier process.

Bob

Lego blocks are also popular.

Cheers

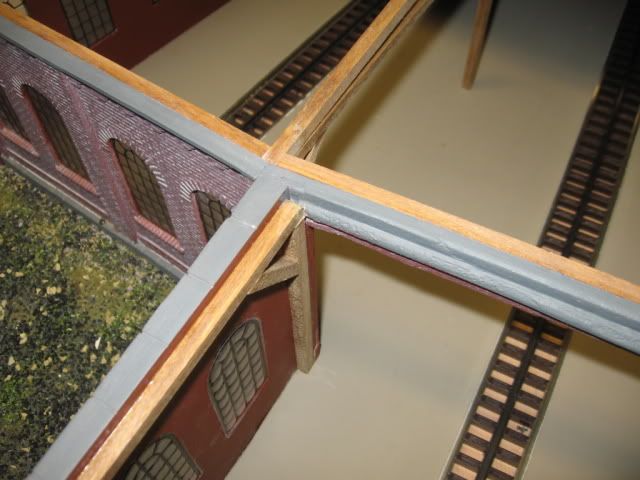

In many of our models especially those with larger walls we provide the 1/4 by 1/4 wood stock for bracing.

This works very well.

In addition some fine a small triangular piece to span the inside corner offeres extra strength.

On styrene or abs model construction, I always cut rectangular or triangular gussets and glue them in corners. I connect them to each other with 1/2-inch wide strips glued to the wall runs to stiffen the structure and prevent warping. I usually place the gussets on 2 to 4 inch centers vertically on a wall.

Alan Graziano

Here are some picture of wood stock in corners. Korber 304 house. The angles are off from 90 degrees, but wood works well.

304 Korber build slideshow.

Lots of good suggestions here. I'm sure more will follow.

I've been using this magnetic jig from MicroMark for years.

I generally use it to make subassemblies of two walls, ensuring that the corner joint thereof is square. I'll add bracing, such as Alan and John suggest...using wood or styrene/ABS...whatever is handy, in the scrap box, etc. Sometimes I'll take more care/measurement when installing those corner braces so that they'll provide support for simple floor inserts (foamcore, thick cardboard, etc.)...view blocks, if you will.

Once I have subassemblies with square corners, I generally glue up the final structure without a jig...but on a flat surface!. Lots of large rubber bands (available in the rubber-band model airplane section of your well stocked LHS...like us!) hold it all together...more bracing added in the new corners.

Another good squaring arrangement for large walls is available if you have a good table saw. If you insert the crosscut fence and position it with the table's rip fence, you have a ready-made 90-degree support for gluing. I'll put a piece of waxed paper on the table surface beneath the work pieces, though, before applying any glues to the walls...don't want drips and runs to mar the table surface!! And that table saw surface covered with waxed paper is a nice flat place to glue up the subassembled walls into the final structure shell. Besides, the table saw surface being generally of steel, you can use magnets, either commercial (see farther down on the above MM link page) or of your own design to hold the walls against the fences.

Like I said...lots of ways to do this...all good!![]()

KD![]()

On styrene or abs model construction, I always cut rectangular or triangular gussets and glue them in corners. I connect them to each other with 1/2-inch wide strips glued to the wall runs to stiffen the structure and prevent warping. I usually place the gussets on 2 to 4 inch centers vertically on a wall.

Alan Graziano

Alan, any chance you can post a photo or two of what you've described in this post? I'm a "visual" learner, so seeing it will help me understand it better! Thanks.

Joe,

I will put something on tomorrow.

Alan Graziano

Joe,

I finally got the computer working so I was able to load the pictures. I used .040" styrene for the walls and the corner gussets and long strips. This is the way I reinforce all styrene structures that I build except for storage tanks.

You must make sure you do not use too much liquid glue on the gussets and stiffener pieces or you will see distortions in the wall. Using liquid glue is like welding. Too much glue (heat) distorts.

Alan Graziano