Actually only one of the A B rails needs to flipped in an either up or down switch position and that would be power; at a straight thru position both A&B rails are ground.

Trying to not keep doing this on a trial and error basis.

thanks in advance.

|

|

Trying to not keep doing this on a trial and error basis.

thanks in advance.

Replies sorted oldest to newest

Alan:

I am still in wiring mode but I use DZ-1000's. So given that:

1- I believe you need two DZ-1008's. One to turn rail A on and off and the other for Rail B. You can't use only one 1008 since each is connected to its own DZ-2500.

I guess one could rig up a connection scheme so that one 1008 is connected to both 2500's but what happens to the 1008 when both 2500's are controlling it is a question for Dennis Zander (Z-Stuff).

Incidentally you may want to try contacting Dennis. He builds the 'stuff'.

Two more comments you best check with Ross or Z-Stuff:

1- I have the three way but it is not wired yet though I seem to remember bench wiring it. I seem to remember that for either motor to throw the rails into a curve the entry rails have to be in the straight position to start with. In other words one motor does not have enough power to push its rail and the other motor's rail to one side (hopefully I said this correctly).

2- If after wiring everything, the 1008 does not function properly check out the red (green?) LED on the 2500. Pull it out and see if the 1008 functions. There was an issue with 'leaky' LEDs - I know for a fact on DZ-1000, whether it crossed over to the 2500 I am not sure. Dennis will replace any bad ones.

Joe

AlanRail, did you get the Ross 3-way working with Dz2500? If so, how did you end up wiring it?

Yes I have two of them. Also non-derailing works for all three track turnouts. Because it is possible to throw the two 2500Cs in a way that will lockup the switch (You can unlock it) I activate the switch from the three non derailing rails with a three-way single pole momentary custom switch.

FIRST you are better off with 4-way but if you must have a 3-Way then you need:

1) 4 diodes; and

2) 2 DZ-1008A SPDT Relay Modules.

3) you need to have way to change the polarity of the center 2 steel (non-blackened) short straight rails using the relays because in the straight position they are outside rail connected; and in the left or right position they change to the center rail polarity.

4) The diodes like all diodes prevent current from going the wrong way which is important for the center position that receives current when triggered by two different DZ-2500C combinations again that is why I use the non-derailing rails to control the two DZ-2500Cs

Preview attachment 20180916_151955_resized.jpg

Preview attachment 20180916_152001_resized.jpg

Preview attachment 20180916_152001_resized.jpg

ttachment 20180916_152140_resized.jpg

ttachment 20180916_152140_resized.jpg

Thanks AlanRail. That looks far too complex for me. I do have it working with two Dz1000's now but it isn't any ideal set up. You might be right about the 4-way. I got this one at e-bay very cheap so I may just replace it. Thanks so much.

good call

Done with DZ 1000s. Key on the non-derail sensor sections is that the Center track requires two sensors, one for each of the two motors, required for this switch. I had to move the sensor section, for one motors, further back away from the frog. Here is the operation of two of the Three way switches. Click on the triangle to access the video. Note the switch point flicker indicating, the switcher has not cleared the non-derail sensor section. There are DZ 1008 used to power route specific dead rail sections, they were not used as part of the DZ 1000 control.

Video shows a Rich Yoder 44 tonner with an early ERR upgrade, electro-couplers and sound. Three way switches are #4's matched to existing #5 switches that we (Fort Pitt Highrailers) had. Here is a link to the module rebuild.

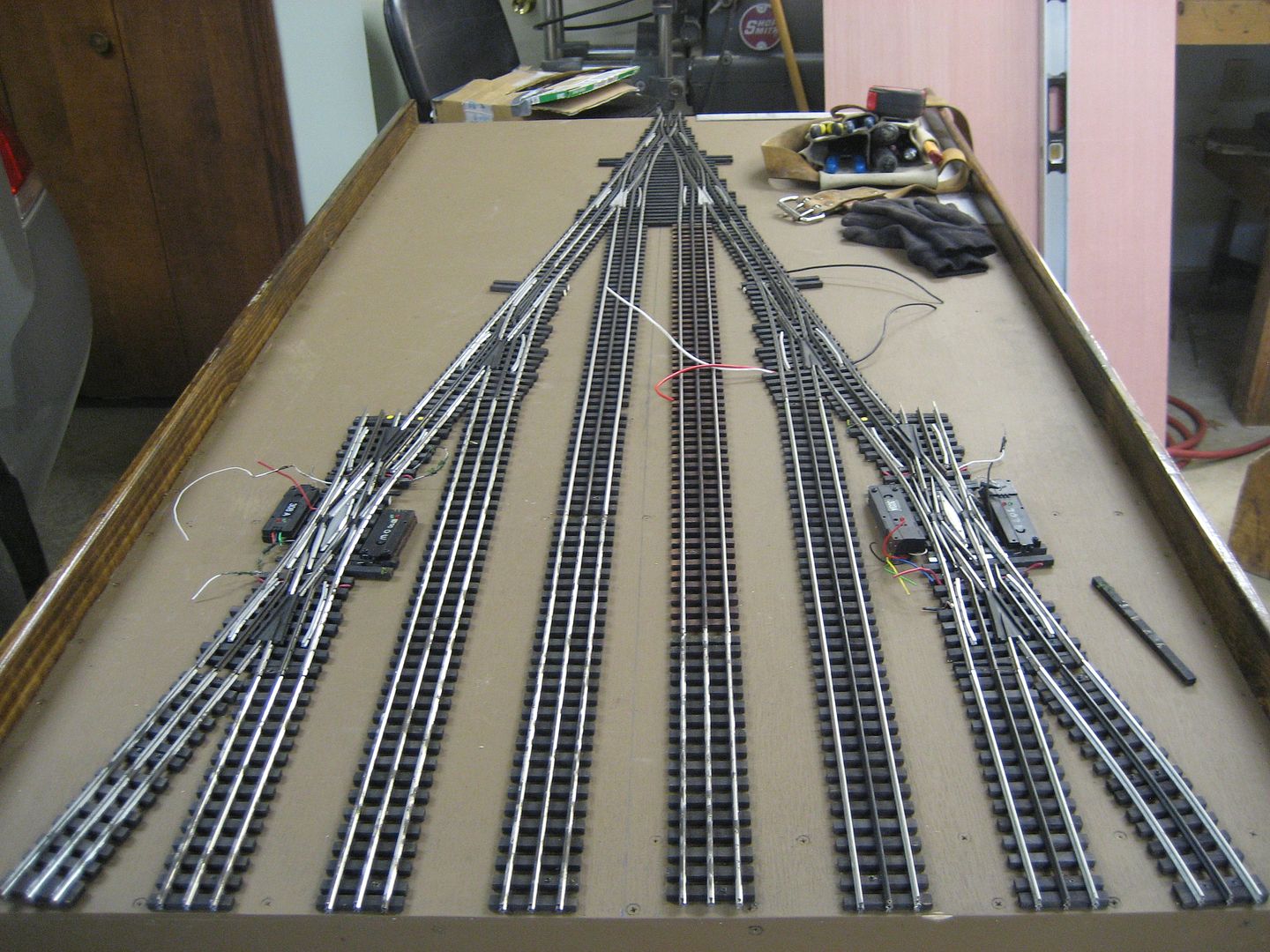

Another project was a yard ladder with an older Curtis/Ross switch and a couple of double slips. Double slips also a two motor switch.

Click on the underlined phrase to link. Module are 6ft (length). There are two additional modules as storage tracks for Fort Pitt Highrailer member trains.

My issue with the DZ-1000s is that they are too high for some of my engines that hit the corners of the switch box; the DZ-2500Cs have a much smaller profile.

MikeCT VERY IMPRESSIVE work with all the turnouts working like that.

Access to this requires an OGR Forum Supporting Membership