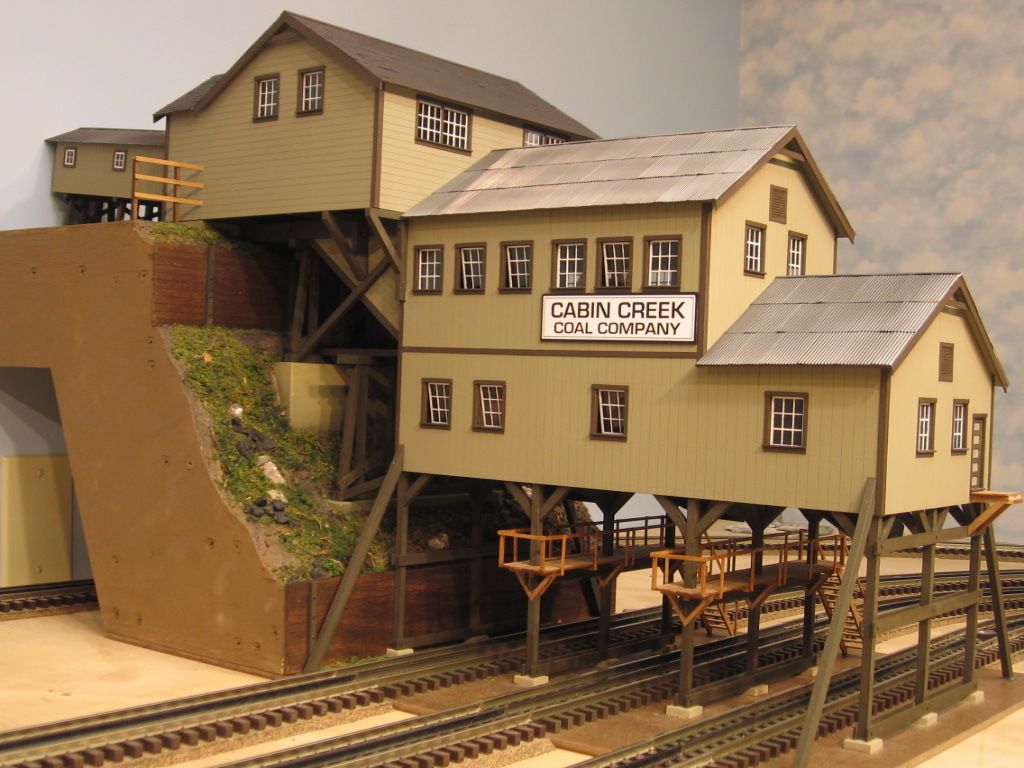

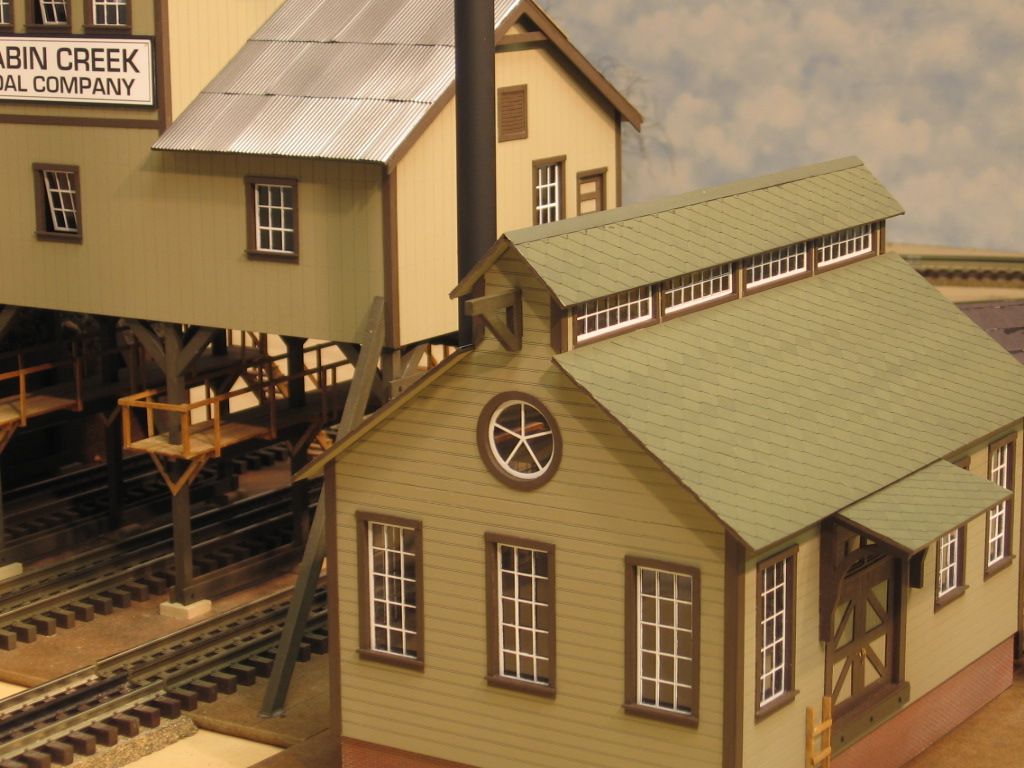

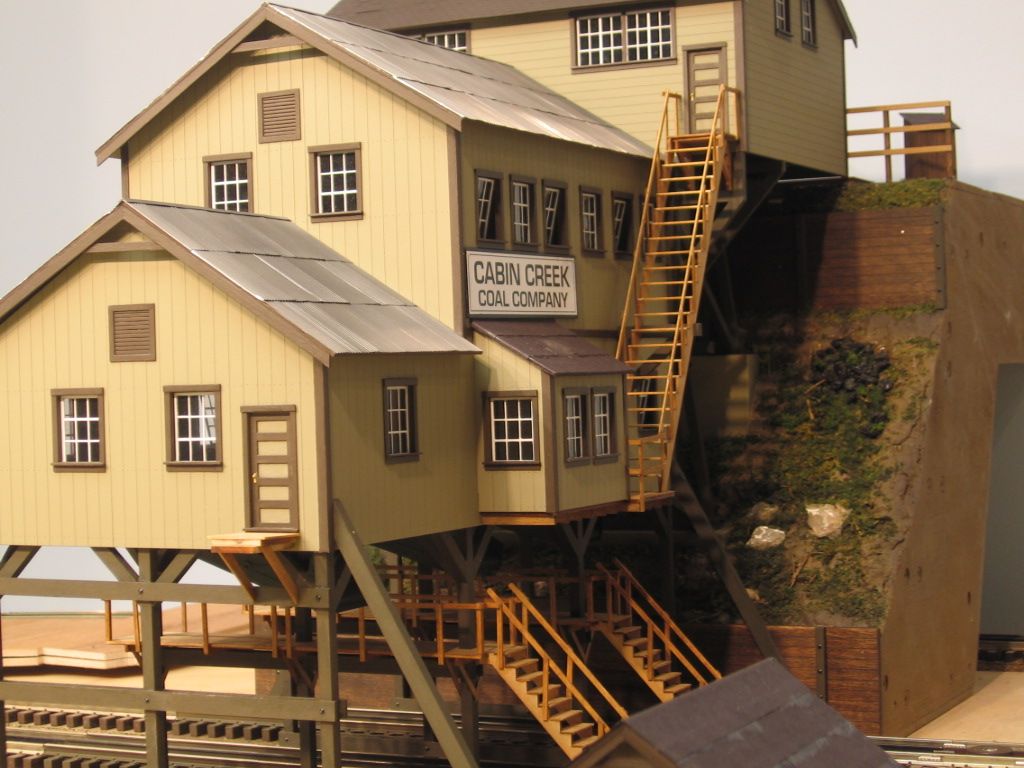

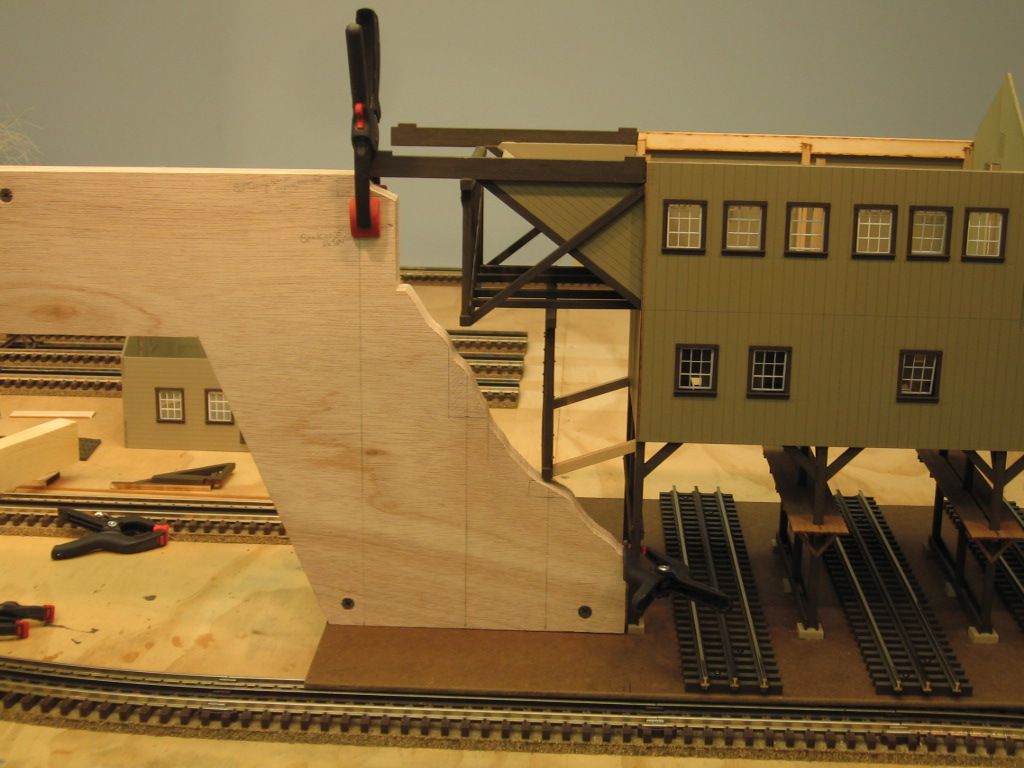

I've purchased BTS Cabin Creek and Mill Creek coal tipple laser kits which when built will be placed in service on my representation of PRR' Tyrone and Clearfield Branch. I probably will make some minor changes to the kits to suit the terrain on the layout. I'd appreciate hearing from those on the forum who have built one or both of the kits about any challenges/lessons learned they have experienced. A rough estimate of how much time it takes to build the model(s) would be of value to me in scheduling the project as there are quite a few others on my project list. Any photos of your finished models would be appreciated.

Ed Rappe