Replies sorted oldest to newest

Looks nevertheless nice are you considering weathering it

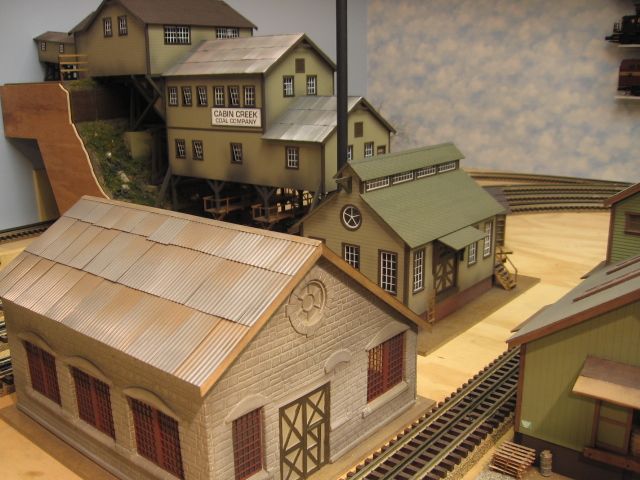

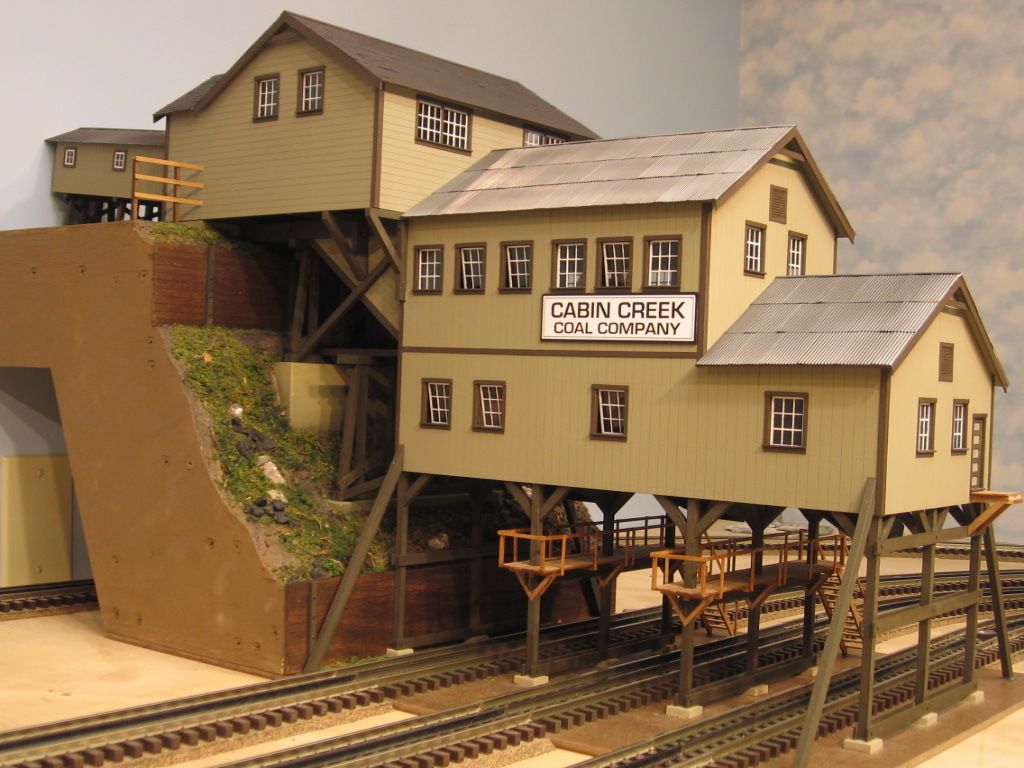

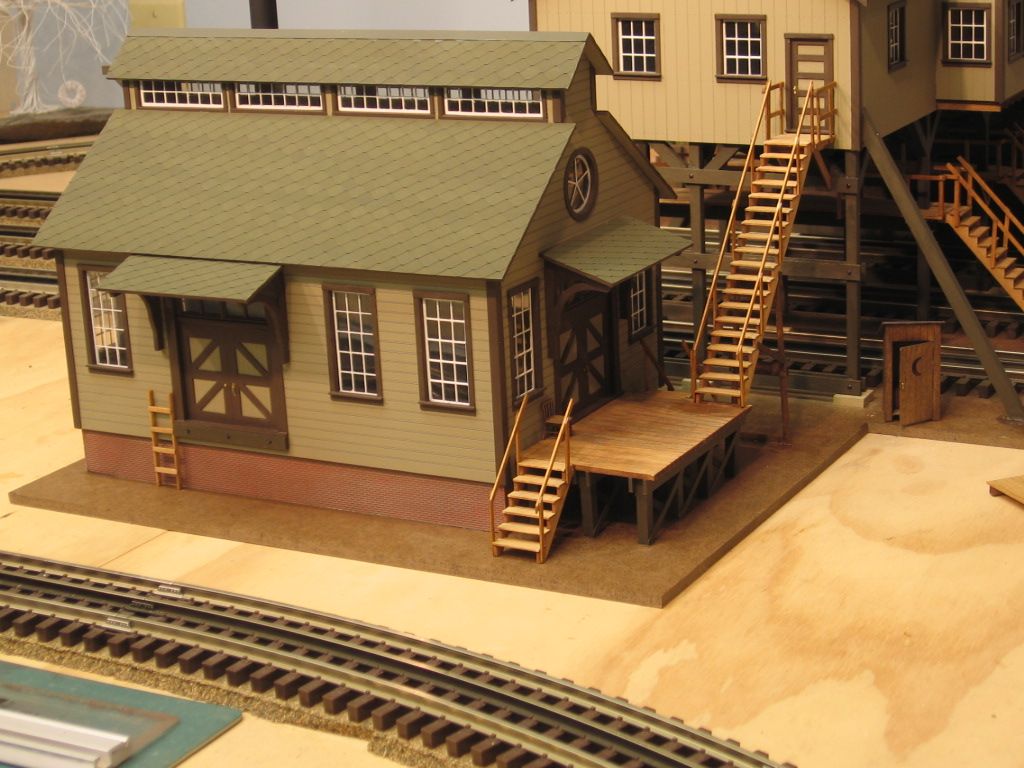

BTS Cabin Creek Coal Tipple. Build pictures slideshow. Click on the underlined phrases to access the two links.

Wow...wow...and more wow.

Here is a link for some reference that I posted before.

http://pagenweb.org/~schuylkill/castles.html

Attachments

Looking great everybody.

I thought it might share some examples of the other end in 12" to 1" scale. These were taken today at PPL Brunner Island power plant after the end of my work day. I thought I would post them just to show the enormity of the scale.

Included are the rotary unloader and the coal pile. Also I have included the two tripper cars that direct the coal into the silos. The tripper cars are actually mounted on a rail system as well.

I have some video of the rotary unloader in action that I will post when it done uploading. The video is taken at a long distance away zoomed in so please forgive any shakiness and the one bit of focus loss.

Attachments

Attachments

![]() Thanks All for the comments.

Thanks All for the comments.![]() I should finish the diorama.

I should finish the diorama.![]()

No problem Popsrr, I am glad you liked it. One thing I noticed is that they are uncoupling all the cars in-between dump cycles. With the rotary couplers and extended air hoses I thought that was unnecessary. My plant contact is in charge of engineering support for the coal yard so I'll have to ask him about it.

No problem Popsrr, I am glad you liked it. One thing I noticed is that they are uncoupling all the cars in-between dump cycles. With the rotary couplers and extended air hoses I thought that was unnecessary. My plant contact is in charge of engineering support for the coal yard so I'll have to ask him about it.

Probably trying to avoid human error like this:

http://princerupertrailimages....y-dumper-mishap.html

![]()

I think that big yellow end on the car has to go the other way!!!!

Holy Cow Wowak! Talked about a bad day!![]()

Then again - maybe they tried to write it off as a free undercarriage inspection!

Holy Cow Wowak! Talked about a bad day!![]()

Then again - maybe they tried to write it off as a free undercarriage inspection!

Wow indeed!!

Popsrr,

sorry If my unloader info hijacked your loader thread. I didn't mean to do that.

Anyway my PPL guy says that the rotary unloader at Brunner does not rotate about the coupler centerline so the cars must be unloaded individually. The same cars are also sent to PPL Montour with an unloader that does spin on the coupler centerline so at Montour the same cars are not uncoupled to be unloaded.

JZ

Wow...wow...and more wow.

Yeah, what he said. ![]()

Pops, that's a terrific structure.

Mike, I am completely blown away by your work. The rust on the conveyer? Really? Wow!!!!!!![]()

George

Popsrr,

sorry If my unloader info hijacked your loader thread. I didn't mean to do that.

Anyway my PPL guy says that the rotary unloader at Brunner does not rotate about the coupler centerline so the cars must be unloaded individually. The same cars are also sent to PPL Montour with an unloader that does spin on the coupler centerline so at Montour the same cars are not uncoupled to be unloaded.

JZ

No problem as far as I am concerned. The more people post the more we learn.

I was wondering if the railroads give any cost breaks to the operations that do the rotary dumping or a pently to the operations that do not?

Seems like the railroads would like to get the job done as quick as they can and get the empty trains headed back for another load as soon as they can??

Popsrr,

sorry If my unloader info hijacked your loader thread. I didn't mean to do that.

Anyway my PPL guy says that the rotary unloader at Brunner does not rotate about the coupler centerline so the cars must be unloaded individually. The same cars are also sent to PPL Montour with an unloader that does spin on the coupler centerline so at Montour the same cars are not uncoupled to be unloaded.

JZ

No problem as far as I am concerned. The more people post the more we learn.

I was wondering if the railroads give any cost breaks to the operations that do the rotary dumping or a pently to the operations that do not?

Seems like the railroads would like to get the job done as quick as they can and get the empty trains headed back for another load as soon as they can??

In the case of PPL they lease the cars themselves so a RR penalty/bonus wouldn't be an issue. If you don't own or lease the cars then there would be a penalty if you had them on your property too long before releasing them back to the RR.

I've worked for other power plants that bottom dumped the coal cars. I don't ever remember anyone mentioning a cost advantage to one method or the other. The biggest thing is the unloading cycle time. The rotary dump is very fast. Additionally because the car gets tipped over the generally all the fuel comes out, even in cold weather. With the bottom dump cars you occasionally have a hard time getting the fuel to fall out if it frozen together in the car. Also you have a car shaker that is used even in good weather when the fuel bridges together in the car. If you don't shake the car you can end up sending back a good amount of fuel you paid for. the car shaker can generally be used to beat up the older steel hoppers pretty hard but you have to just pulse the button when shaking an aluminum car or you could shake it apart.

In both cases the speed of the belt and hopper system underneath is often the limiting factor for unloading speed. The plant i worked at with the bottom dump could unload two cars at once, each car took about 7 seconds to unload. Obviously longer if you had to bump the cars with the shaker. It was always something to see the springs on the cars start jumping back up as the weight came off the car.

Again the rotary dump, in my opinion does a better job. However the capital and maintenance cost are of course higher.