Thought I would provide some feed back on this unit. There is evidence that the unit was opened before, as the ACREG had the heat shrink cutoff and then taped back on.

There are only 4 screws to hold the shell on. 2 all the way forward and 2 under the cab. The 2 all the way forward were missing.

The smoke switch was popped off and the internal metal contact was missing, so the switch would not work if put back together.

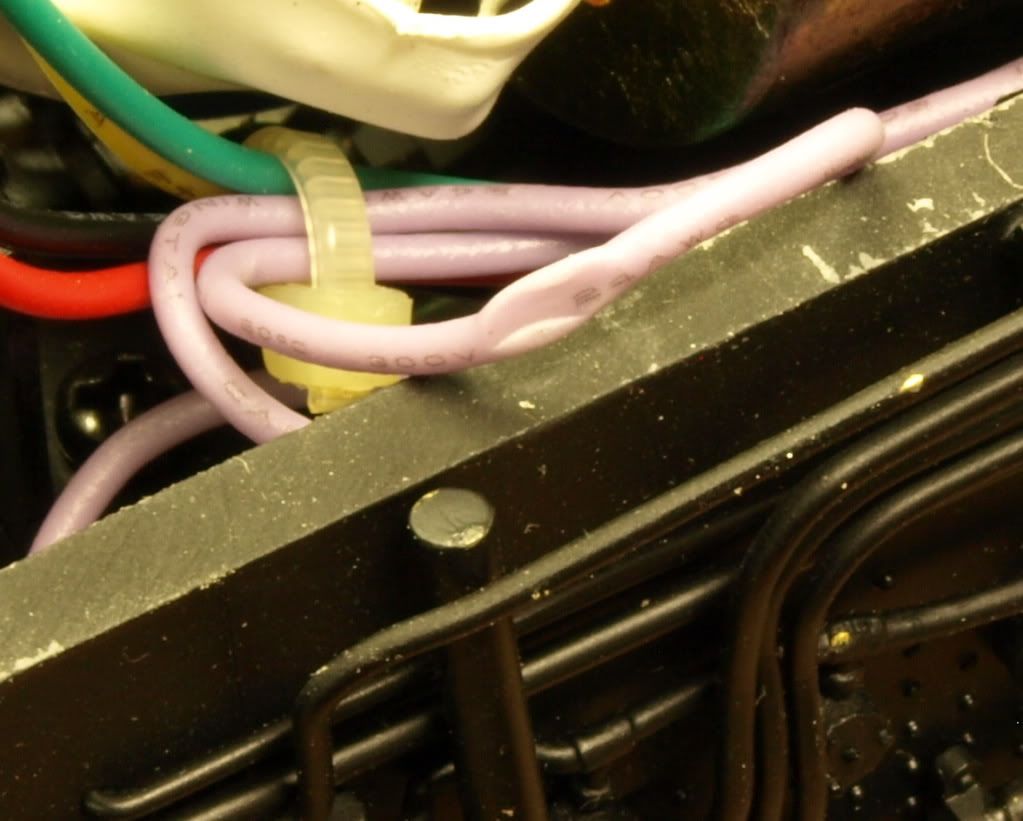

There also were some pinched wires.

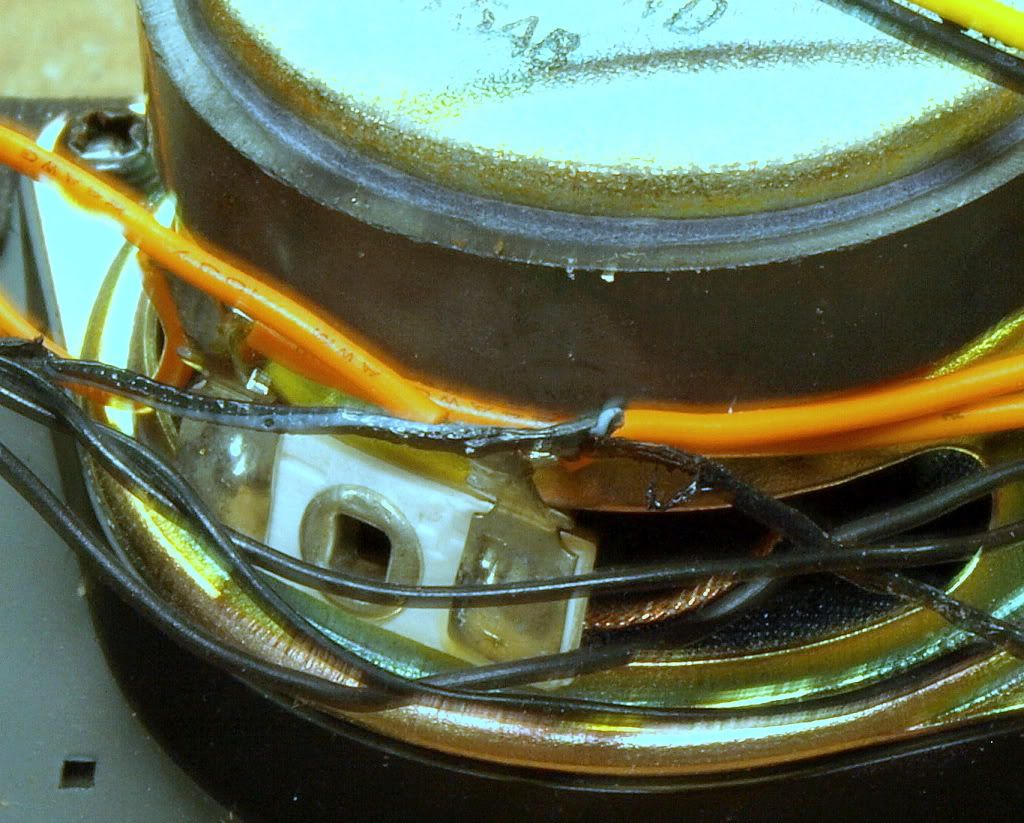

As far as the stack obstruction, there actually was one. The wire harness to the front lights/markers has heat shrink and doesn't have much room in relationship to the smoke unit. Part of the heat shrink was trapped between the funnel and shell.

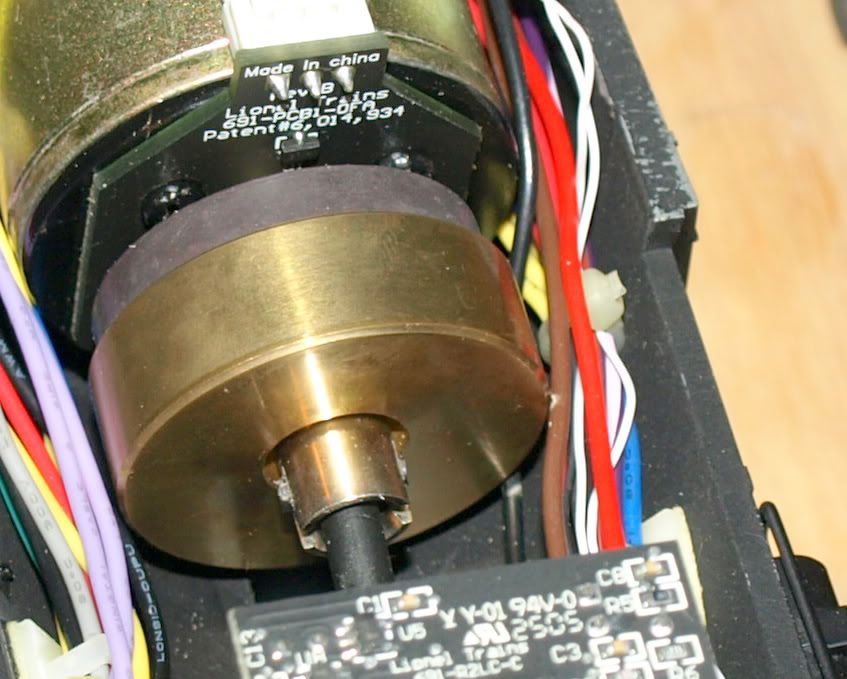

This is a smart smoke unit, so it is not modifiable like other units. It uses a 6 ohm unit. It was also wired differently then others I have seen. The AC input went direct to the ACREG so it would always be powered when track power is on. The Element Hot lead goes to the switch, so the switch turns off power to the heating element only.

The smoke unit also get AC power and Serial data, but no chuff input via the cherry switch like some models do. So the smart unit must sense serial data chuff and trigger fan that way. Fan only puffs when in motion and chuffing.

I did remove the element sleeve and repack the wick. I do believe you can set a H, M, L via the TMCC for this model. I believe M is the default and locked in for conventional operation.

It is a nice model, but does have a lot of fragile detail parts. G