The 3-way switches have some complications and disadvantages for 3-rail applications and it's worth considering alternate track arrangements that use conventional switches. 3-way switches are relatively uncommon on real railroads and would only be used in special cases.

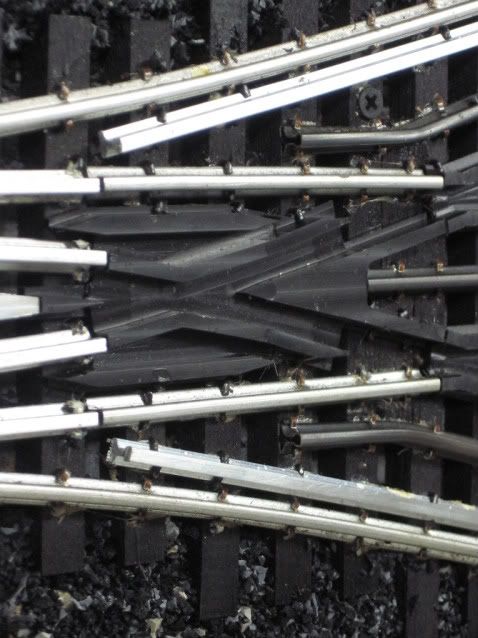

In Mike's photo, the 3-way switches look cool but more typical crossovers could have fit in the same space. These Ross 3-way switches have a 14-degree angle of divergence equal to that of a #4 switch. Crossovers with #6 switches might have been more appropriate for mainline tracks where space was available.

If additional length is available, it's a good idea to add some space between consecutive switches to relieve S-curves, and to avoid possible problems with the center-rail dead spots being too close together for some locos.