MikeCT,

One question on those atlas boards and signals, if you manually throw the switch, do the signals change, or do they only change when electrically thrown via button or anti-derail?

Also On this comment: "Can be done a couple of ways. Additional input wiring from different devices, I used as mentioned ASC controllers. Which will handle (4) switches per controller. Lionel SC-2's will do (6) switches. " My point was with the home built version, no SC-2's are needed at all, saving quite a bit of cash, if one wanted control from a single hand-held remote.

RRMAN, RTR12, and JohnF,

Using Arduino was my plan, allowing the micro-controller to handle all of the timing. In this case the program is pretty simple. boiling down to a routine that says "if input 1 is turned on, turn on output 1 ... but only for 2 seconds (or however long is needed.). Then repeated for each switch input and output. In this case I'm not particularly concerned about the program, or programing. I'm willing to teach it if folks want to learn, but in this case I think it would be easiest for everyone for me just to write something that works. I don't expect it to be all that complex.

JohnF, Based on your reply above, it seems the best solution would be to have two controllers, one for the yard and yard area switches, and one for the rest of the layout. the design of each of these controllers will be exactly the same, each one capable of running 32 switches. (It would not be significantly more difficult to use 4 controllers for 16 switches each, if it would be easier to install that way)

With the mention of having a second set of pushbuttons at the main control area for the yard, I think it useful to design this feature in from the start, and it can be done pretty easily with just 2 or 3 wires running from the main control panel to the yard. If that seems like a good idea, the switch controller for the main panel will end up with a couple extra parts, but nothing much different, really.

The design I have in mind will have 4 main parts. 1: A power supply for triggering anti-derail and push-button inputs. 2: An Input control board. 3: A micro-controller (Arduino) to read inputs, send outputs, and provide the timing function. 4: An Output control board to drive the switch machines. for all of these there are many ways to get the job done, but I'm going to outline the way I would do it. We can discuss other options if you like.

1: the power supply.

To trigger the switches from isolated rails, it is very convent to add an additional DC power supply to the layout. This supply would have it's ground side connected to the outer rail of the layout, using insulated rails to conduct signals back to the controller. The + side of the supply is connected only to the controller unit, and the supply will have no effect on how the rest of the layout functions. For this method to work, however, all the outside rails must be connected throughout the layout.

2. Input control:

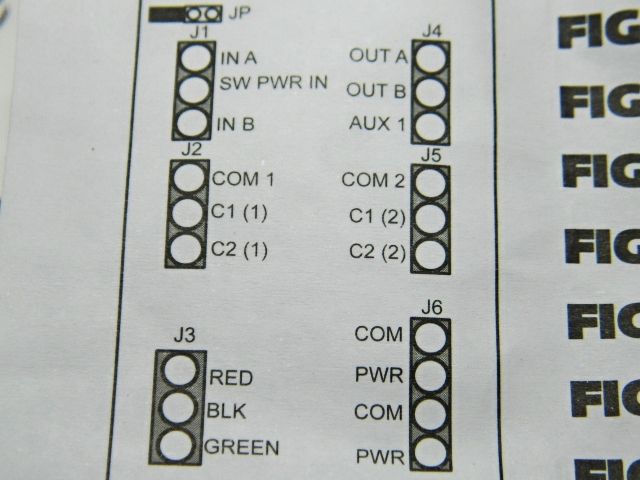

Here wires from each isolated rail for the anti-derail as well as connections from the pushbuttons will come together in one place. Each input will then have an opto-isolator to separate the layout from the controller, protecting from spikes and such. From there the signals will be sent into parallel to serial shift registers. I have the super common 74HC165 in mind, which will allow us to use only two or three pins on the Arduino for as many inputs as we want. If this seems overly complex, don't worry, it's really not. Think of this part like a toll booth plaza on a highway, 8 lanes of traffic merge into just 1 lane.

3. Micro-controller:

A simple Arduino Uno or even less expensive Nano, will likely do the job just fine here. the controller will be set up so that it constantly monitors all the inputs, and when it detects a train triggering anti-derail, or a manual button push to throw a switch, it will then turn on the correct output for a preset amount of time. We could also add support for dwarf signals and the like if it is wanted. it's not that hard once we're this far already.

4: Output.

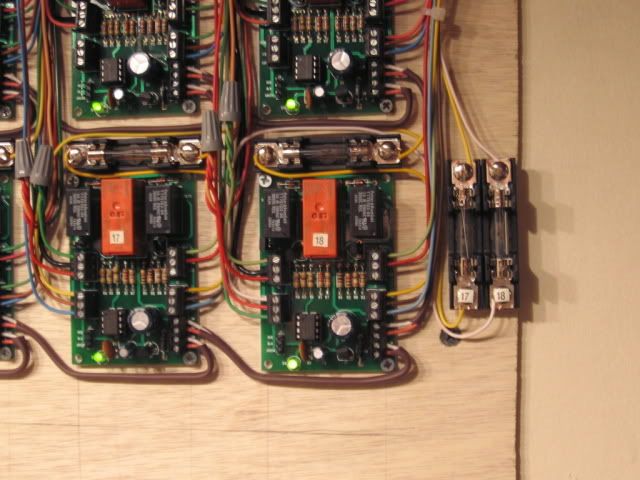

This part takes signals from the Arduino and sends them to the switch machines. The first stage is the use of serial to parallel shift registers. (74HC595) these work the opposite of the input side, allowing one output pin to be split up into many separate output channels. From here the signal can be sent to relay board modules. The most cost effective ones are the 16 relay boards, which would control 8 switches each if set up for the simplest wiring. There are ways to wire things to get away with less relays, if that's something you'd like to discuss. You could also use triacs instead of relays, but this would involve hand soldering the boards which could be tedious, also folks around here seem to prefer relays for such things. If wanted, provisions for dwarf signals, or panel indicators could also be added to the output stage, at very minimal cost.

If this all seems like a lot, well, it is more complex than buying a ready made solution. On the other hand, the heavy lifting here is still done with pre-built modules. For construction, you could get away with using solderless bread board, though a soldered board would probably be preferred.

I think I have enough parts on hand to build a demo of how this all would look, and I'll probably do that when I get out of work tonight, if nothing else just to show it is not nearly as complex as it sounds.

One last question, what is the desired cut-off time for the switch machines? This can be anything from 1/10th of a second up, so let me know what a good amount of time to insure the switch fully throws is.

JGL