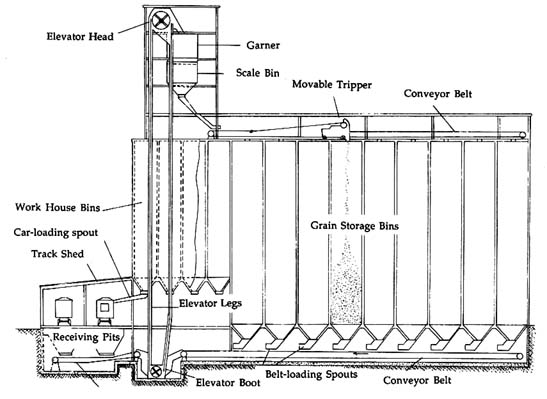

Ok, I have a semi completed Korber 6 silo Grain elevator. I was looking to place an interior in the square structure/elevator portion. What would that look like on the inside if I left a wall out to view?

How does this model of a concrete facility basically work? Would I see Pipes for the grain in that square structure? IS it assumed this facility has a "basement?"

Thanks in advance for your imput. Inquiring minds would like to know!