Am putting a layout together, approximately 18 x 15 using 3 rail Lionel switches and track. Will be using a ZW for power. What is the minimum wire guage I should be using for the "control" circuts for switch position. Will be powering the switches with constant voltage from the ZW. I'm thinking the longest run from the control panel to the furtherest switch will be about 20 feet after routing the wire under the layout.

Replies sorted oldest to newest

You have very low current draw on the coils for switches. 20 gauge is more than fine.

Gilly

Would 24 be to light?

I used 24 gauge wire that I had on hand to wire switches on my 8 by 12 layout. I never experienced any problems.

As Gilly noted 20ga is fine. I used 18 ga solid thermostat cable, commonly available at local electrical supplies. It is available in (2,3,4,.... ![]() conductors per cable which works for most switch motor/control button applications. The same is available in 20 ga. , maybe harder to find.

conductors per cable which works for most switch motor/control button applications. The same is available in 20 ga. , maybe harder to find.

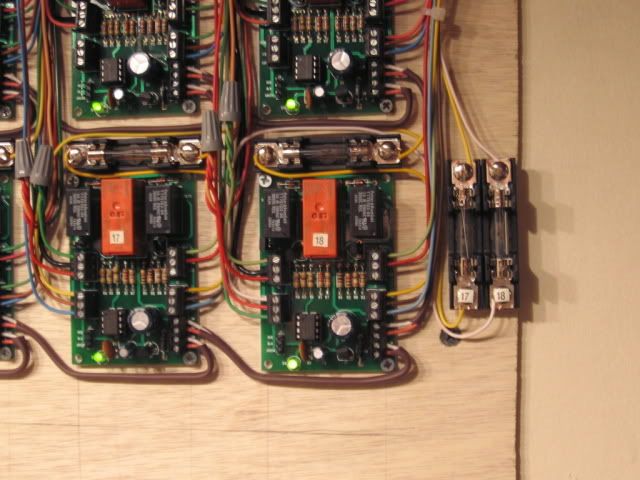

A little more intense, this is an Atlas 6924 Switch relay board installation 18 ga solid thermostat wire. Note the colors.

Would 24 be to light?

Not really, I just don't enjoy skinning insulation on the smaller sizes. I started to mention thermostat wire too, but in my world stranded wire is more common.

Gilly

Another source of useful wire for these tasks is telephone cable. Four #22 conductors and very easy to work with. CAT5 Ethernet cable has 8 #23 or #24 conductors, depending on what you buy.

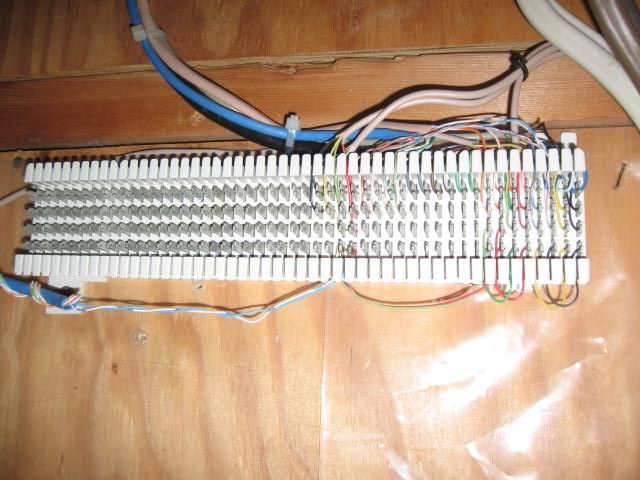

Using standard "D" Telephone station wire works well for installing switch machines. Normally found in either 22/24 gauge solid wire 4 conductor red green black and yellow. Also utilizing the standard 66M1-50 connector block available at many electronics supply houses or HD or Lowe's makes the wiring very easy quick and neat. A single 66 block allows you to terminate 32 twin coil type motors or 50 Tortise style motors (motor only). I have used them since entering the hobby around 1980 and never had a problem using this method.

Attachments

Larger picture of a 66 Block. Installation does not require stripping insulation from the wire. Requires a punch down tool. These blocks as pictured allow (4) wires to be connected together per horizontal strip. There are split blocks, where the (4) terminals are split in the middle, and if desired, can be connected with a bridge-ing clip.

Ideal punch down tool from the Grainger website. An impact tool, that installs and cuts the wire. There are two types of installations, 66 pictured, and 110 a different type of modular terminal block. both the 66 and 110 punch/cutters will fit the impact tool.

I use 4 conductor phone wire.....just be CARE-full when you strip the ends.If you NICK the ends they will break off when you are moving them around to make the connection.