I'm planning to install an upgraded Bowser 36" turntable and cannot find a video or wiring diagram that explains how to provide power to the turntable, roundhouse track and spurs to the main layout. Any suggestions ould be apprciated.

Joe

|

|

I'm planning to install an upgraded Bowser 36" turntable and cannot find a video or wiring diagram that explains how to provide power to the turntable, roundhouse track and spurs to the main layout. Any suggestions ould be apprciated.

Joe

Replies sorted oldest to newest

Hey Joe,

Your first step maybe to get the turntable and motor to work reliably. The current motor / friction wheel to plywood circle has a lot to be desired. I know, I have one sitting in the corner giving me the evil eye... the motor / rubber wheel does not apply enough force sometimes to turn the table.

Are you using the current powered motor set up? Or moving to some other motor and pulley / belt drive system?

First off, does the TT swing effortlessly? That is the most important thing to ensure.

You can upgrade the motor. You may wish to up grade the spring.

The best thing to do for the drive is to purchase the Millhouse drive kit.

I am running three Bowser and two Millhouse TTs. I also use MRC 6200 and MRC 9500 power packs to power the motors. They slow down nicely for visual alignment. Better power packs will provide excellent control.

I am considering an indexing set up for one TT but really do not need it for all because all my other TTs are close to an operator.

To power the stub tracks I either use a rotary or individual push on/off.

Some bowser TTs have split rails, some have solid rails and use the center pin for ground.

Position the split of the rails away from stub tracks, someplace where the TT would never stop.

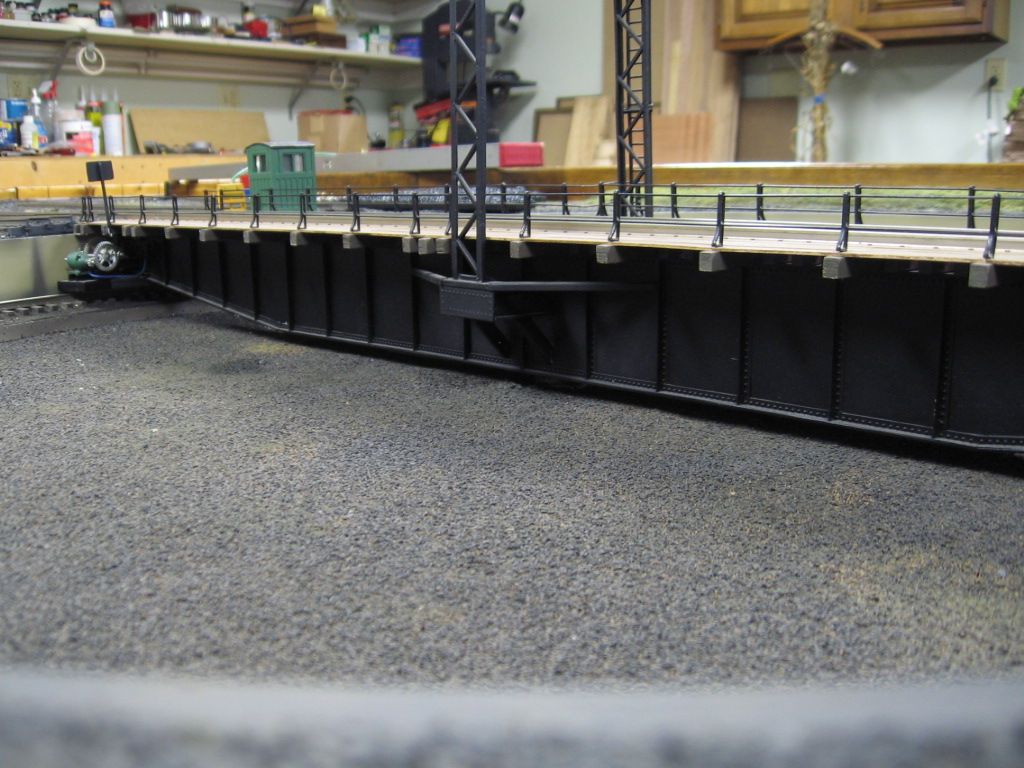

Wiring the TT and tracks is really no different than the rest of the layout. We used a separate distribution block for all of our engine facility tracks (the big MTH one) and just ran red and black wires to each track. All the commons are tied together. Each track also has a SPST toggle to turn power on and off (red wire, center rail) so engines can sit there without power running through them.

As mentioned above, make sure your TT runs flawlessly before making anything permanent. Upgrade the drive to the Millhouse kit. If it doesnt work correctly, you will NEVER use it.

Thanks to everyone who offered advice. I have removed the old Boswer drive motor and system and replaced it with a direct drive kit that I purchased at York. It!s installed and the turntable works smoothly.

If I read the comments correctly, I should run a red wire from each spur center rail (hot) to a toggle switch and then to a to a terminal strip. Feed power to the terminal strip from the main line. Run a black wire from the outside rail on each spur to the common side of the terminal block, and attach the common side of the terminal strip to the ground on the main line.

Do I run a seperate feed from the terminal strip to the turntable track? DO ai control power to the turntable track with another toggle switch?

Yes to your questions, that is how I have it.

I do not use a toggle for my turntable, my though was I would never park a engine on the turntable and still need power for my turntable "area", which also powers all the spurs where engines sits. You could if you wanted to.

Which drive did you buy at York?

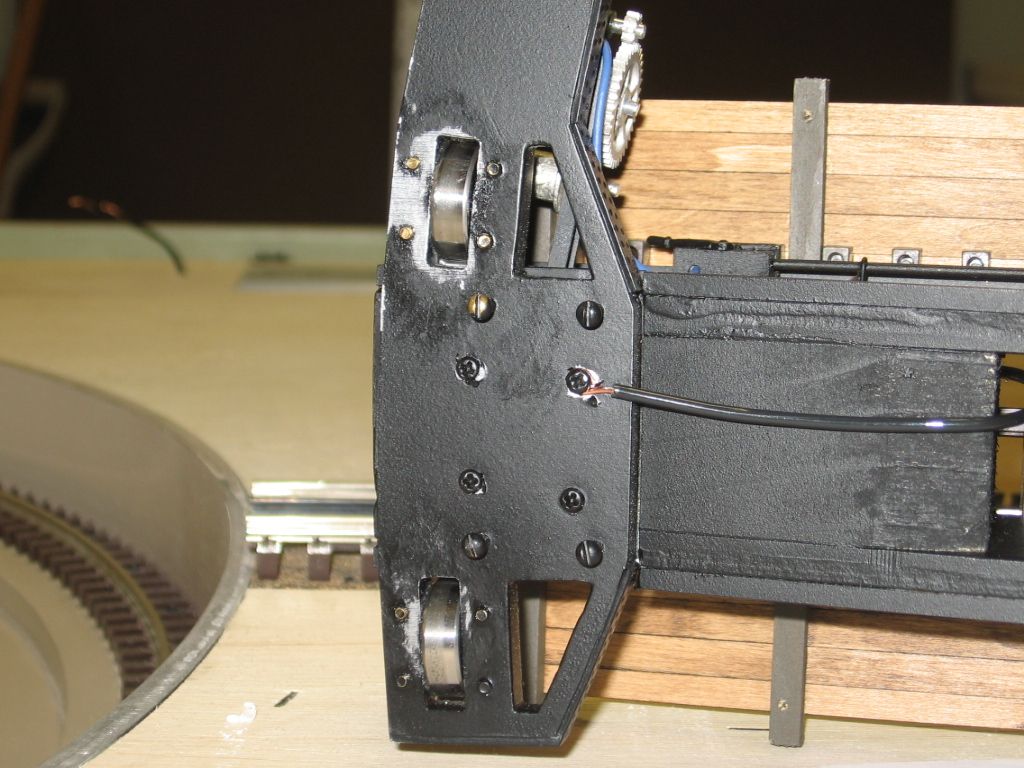

Turntable power is via two contacts. One, (Power) the center pivot thrust bearing, Two, (Common), the pit rail, and associated roller bearing boggies. Here are a few pictures.

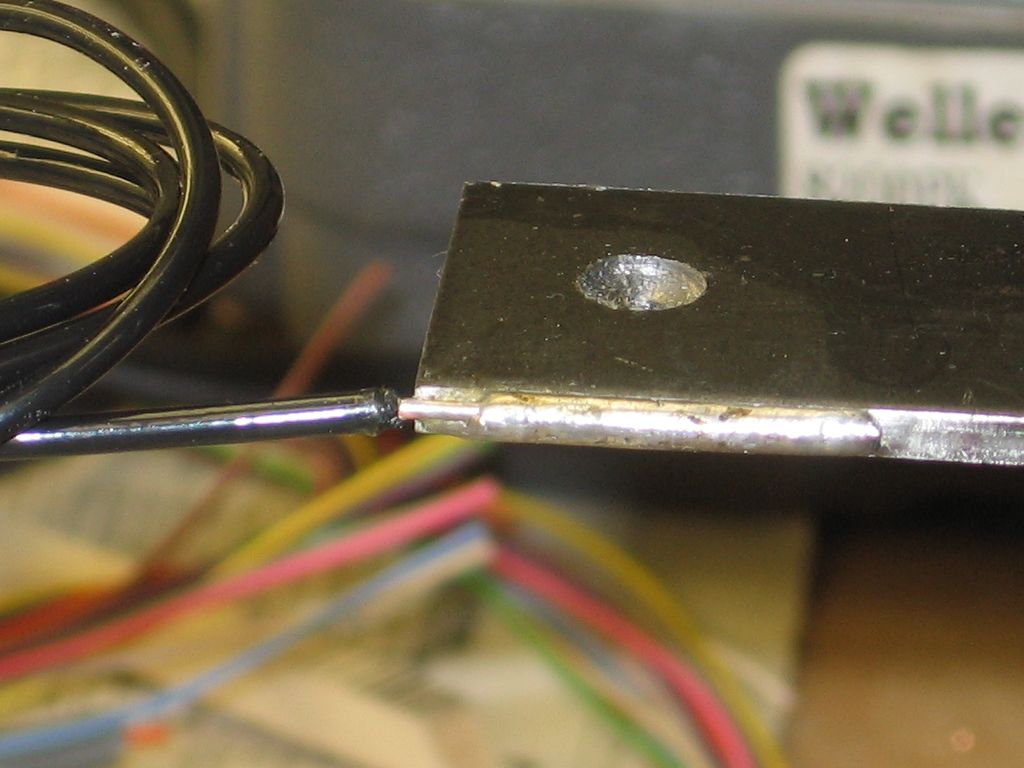

Center bearing of the turntable.

Brass contact, on the turn shaft and the metal part of the turntable block.

Under side of the turntable the black wire, taped to the pit with duct tape, is soldered to the thrust bushing. Power through the thrust bushing and metal shaft/t-bar provides power to the center rail.

This wire is attached to the center rail. A second wire of the other end of the t-bar also attaches to the center rail.

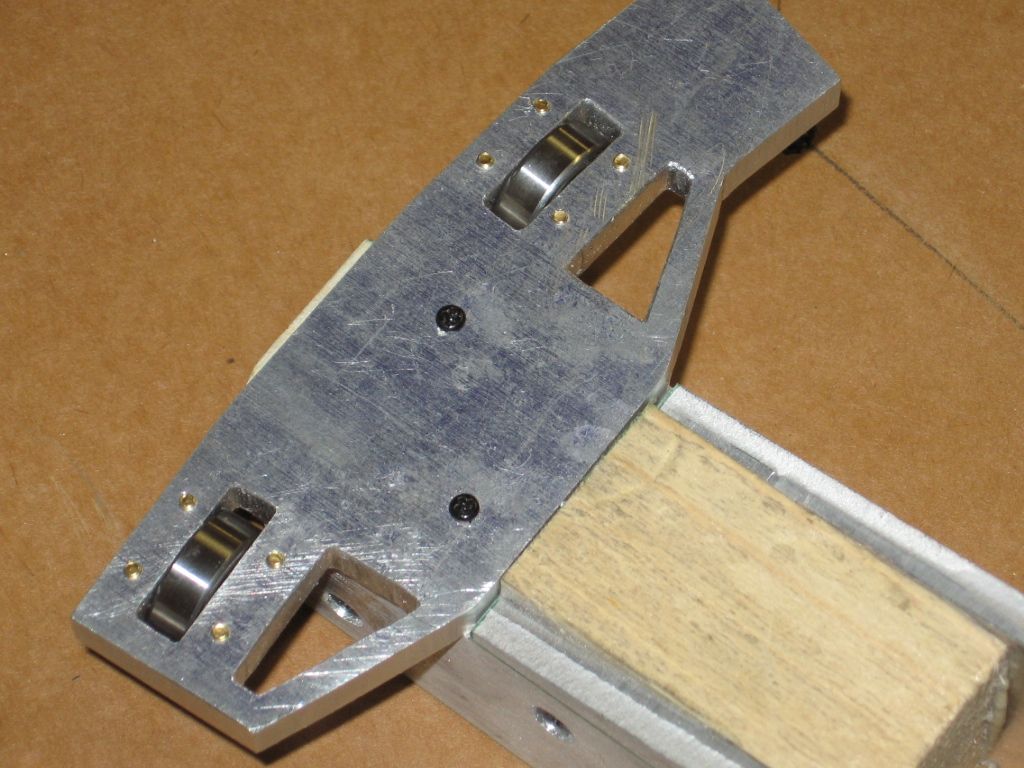

Pictured below the wire attached with the brass screw is from the pivot t-bar. Other wire is attached to the pit rail boggie.

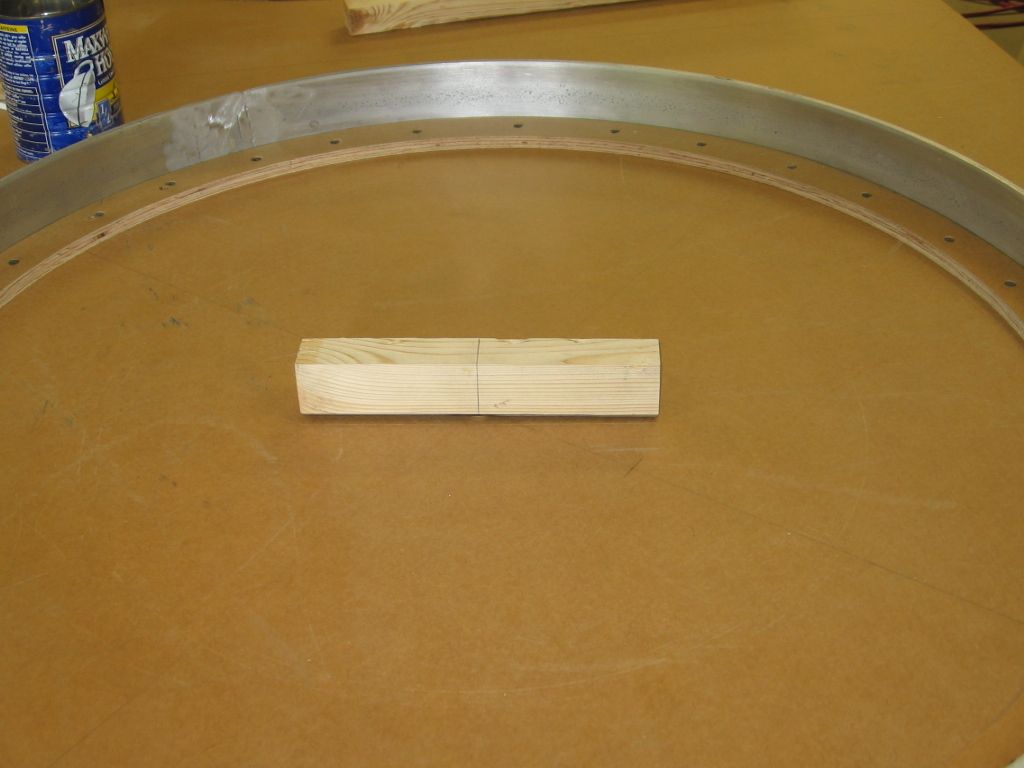

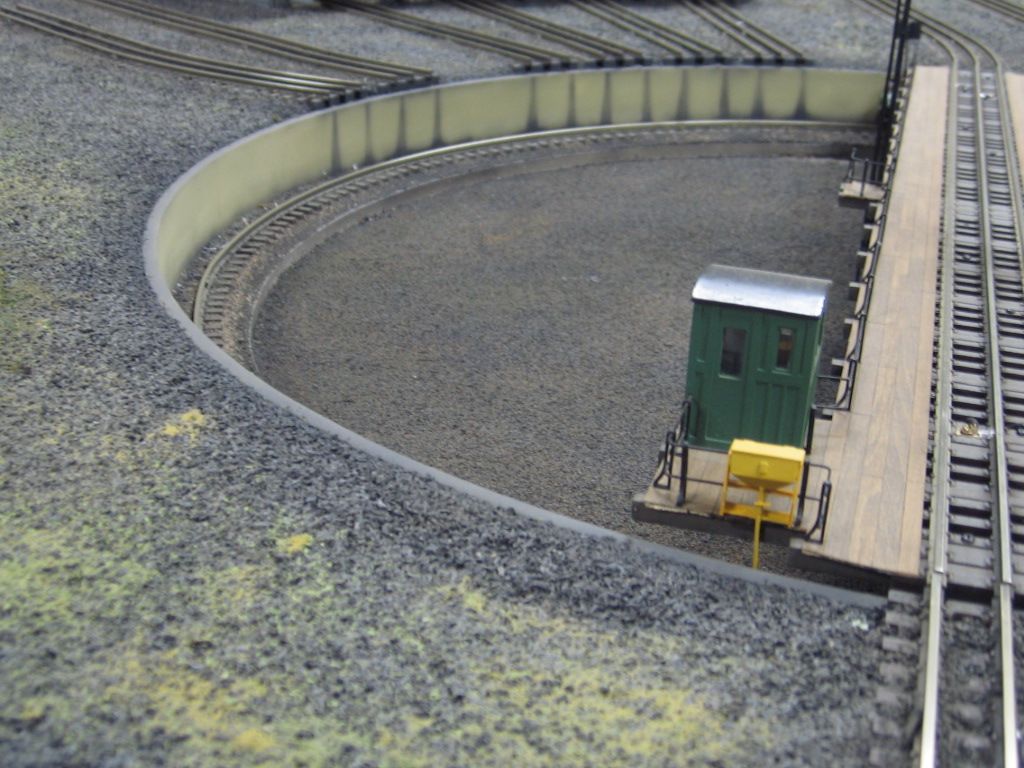

Pit rail.

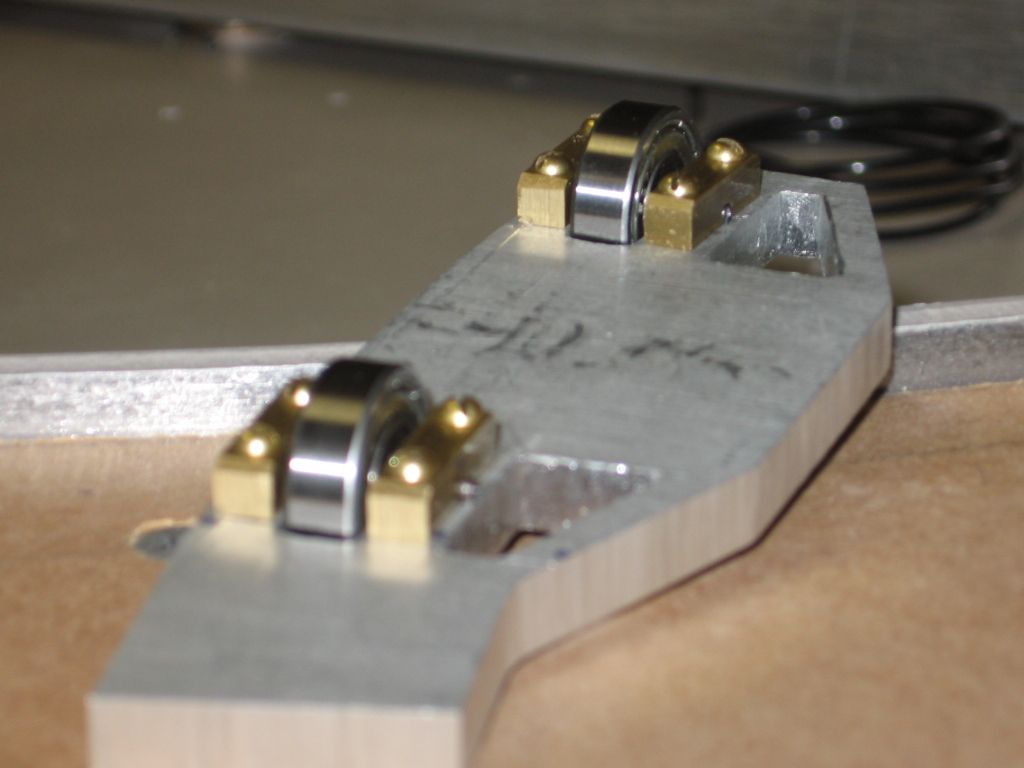

Pit rail boggies

Wire attached to the boggie is connected to both outside rails.

Access to this requires an OGR Forum Supporting Membership