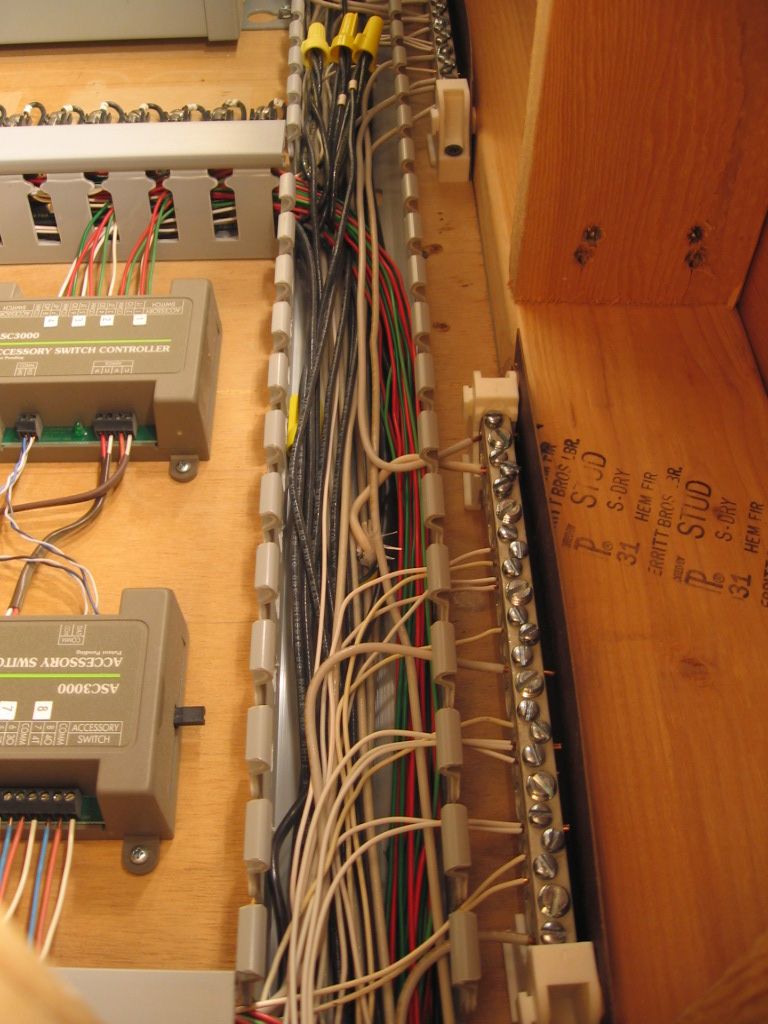

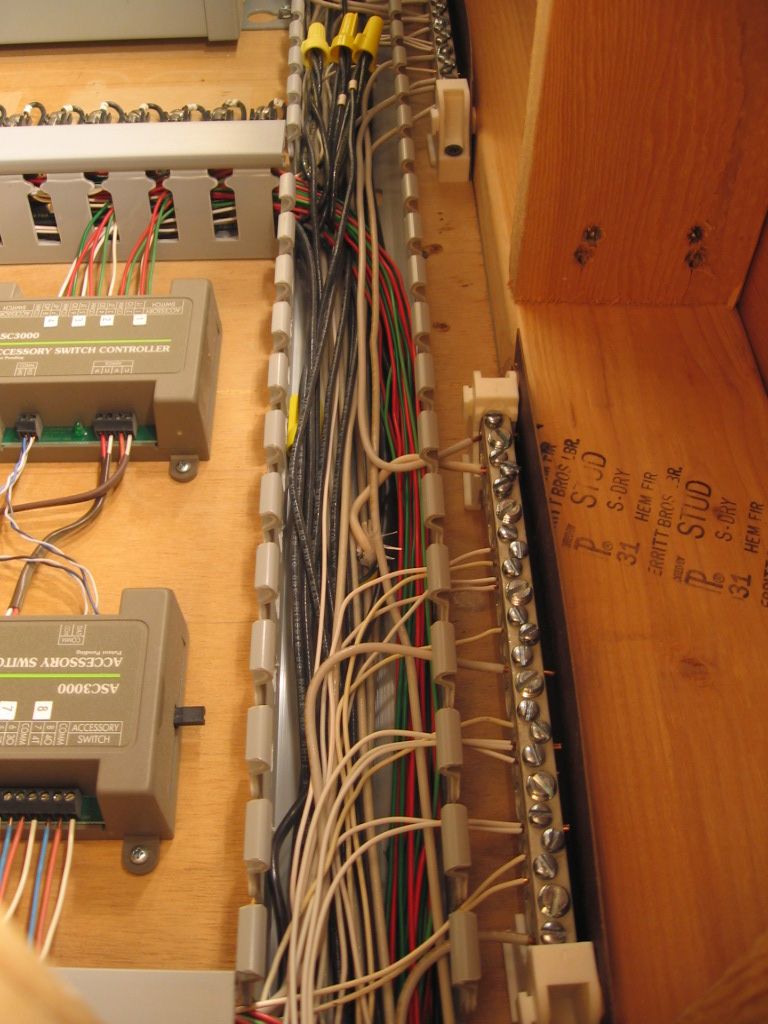

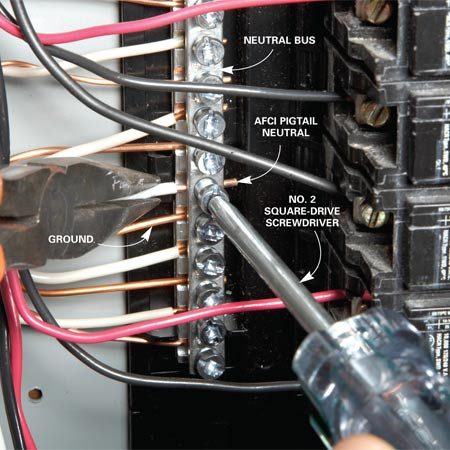

There are two types of bars. A ground bar is usually un-insulated. A neutral bar is insulated, and comes with plastic mounting post. Either would be acceptable for model train wiring at 18 volts (low voltage wiring). This type of termination worked well to 18 ga solid wire (I used thermostat cable and 18 ga THHN single strand solid conductor for accessory/switch wiring and 14ga solid THHN wire for track power). You may find that 18ga stranded and smaller may not work as well with this type of termination designed for residentual wiring, most likely 14 ga and larger. Note the two conductors terminated under one screw, acceptable here, but not in standard house wiring (One terminal, one wire). Be sure your termination is tight.

I used the neutral bars, note the insulation post on the end of the bars.

Working track feeds and accessory/switch motor feeds back to the power distribution center, Commons, usually the white wires, are picked off and terminated on these electrical connection bars. Eventually, using automatic non-de-rail switching, track common and accessory common become the same by jumpering between buss bars.

Common termination complete. Track power, accessory power and switch power are handle via other devices pictured. Note that track and accessory fusing has been added.

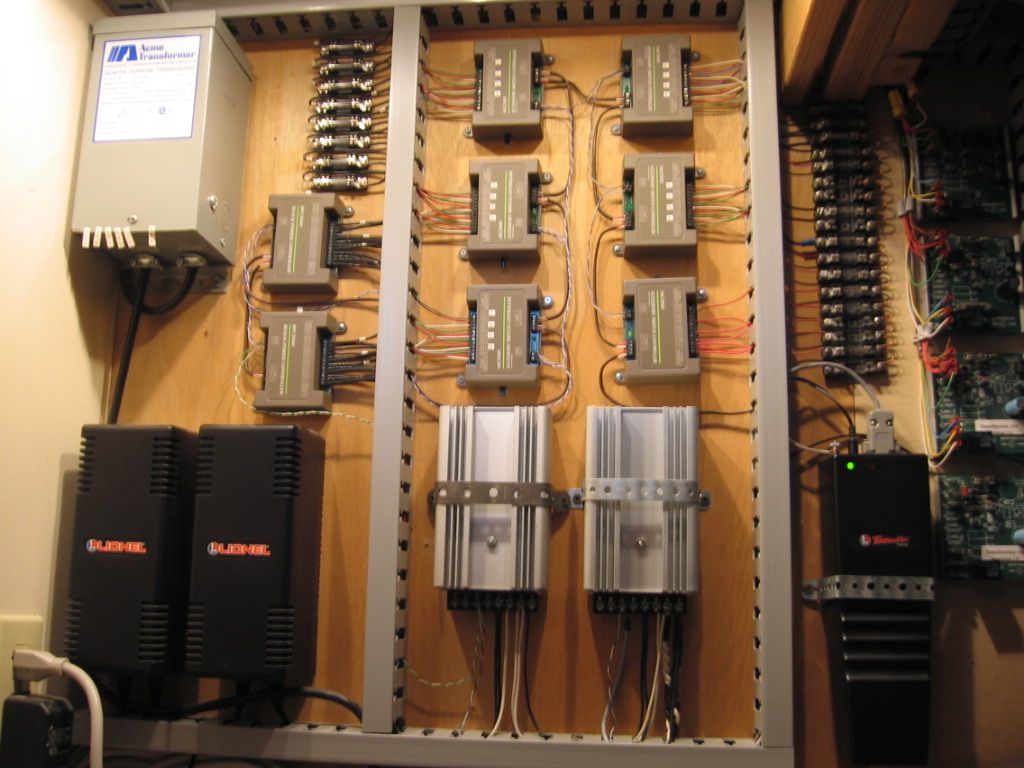

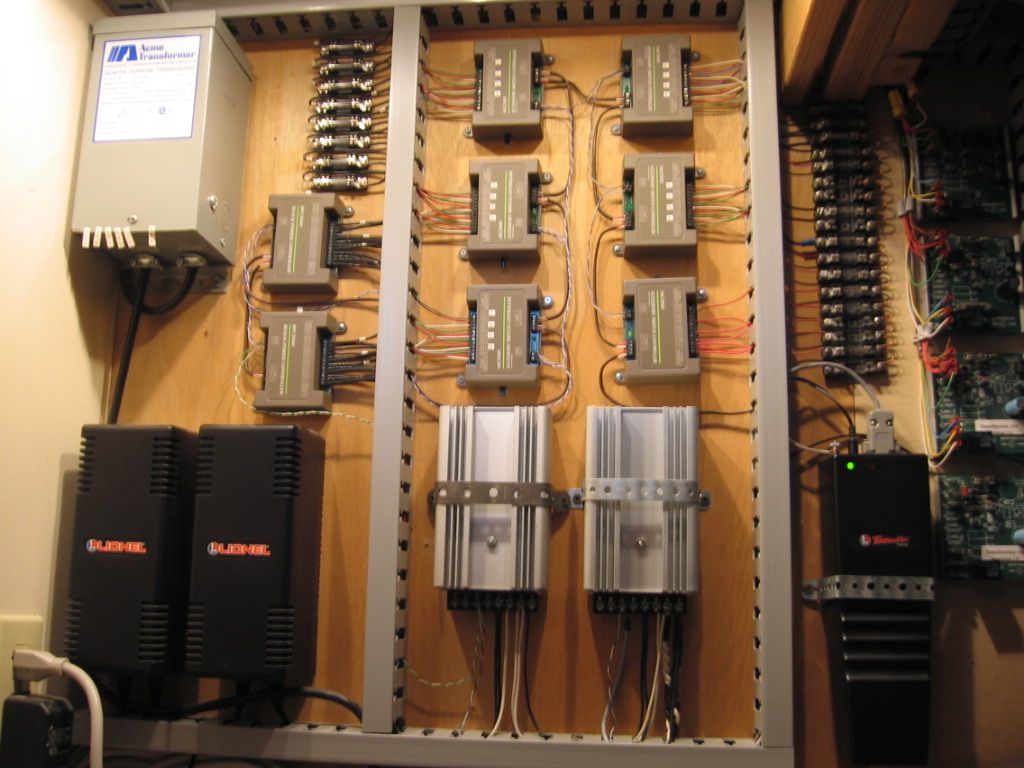

Track block fusing upper left, (8) circuits. Accessory and switch power fusing right.

Two grey IC Controls boxes (BPC's, Block Power Controllers) to the left switch track blocks. (8)

(5) of the (6) grey IC Controls device boxes (ASC, Accessory Switch Controllers) to the right switch Atlas switches. The one remaining control lower left does accessory switching, off and on. All control is via a Cab1 remote via ACC(Accessory) or SW(Switch) commands.

Important to note that there have been some issues of late on this forum that some of this is too techno...... , way beyond comprehension. In the "Keep in simple" environment, please note that all of this is done (One Wire, one device, At A Time)

Mike CT

this is the pic of one. but can you use do this for our trains?

this is the pic of one. but can you use do this for our trains?