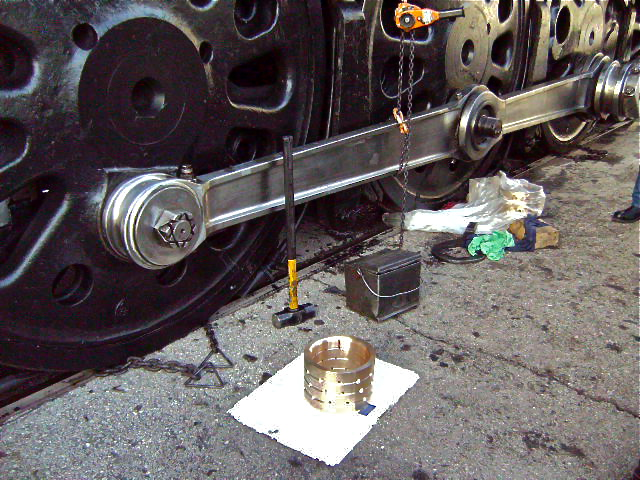

Plain bearings in side rods need more clearance than a typical plain bearing application where the bushing is in a fixed position relative to the mating shaft. As the locomotive moves over the track, the wheels move up and down in relation to each other. At extreme points of suspension travel, the center-to-center distance between the crankpins is increased by a certain amount compared to when the wheels are even with each other. Although this amount of elongation would be considered negligible by the average person, it can easily exceed the typical clearance of a plain bearing in a fixed application (such as inside an internal combustion engine). As Hot Water pointed out, the mechanical department has specified a clearance for the side rod bushings. The mechanical engineers would have taken into account the extra clearance needed for the wheels to be able to travel to the extreme limits of the suspension travel, and the accompanying elongation of the center-to-center distance between the crankpins. To further complicate matters, a dip in the track (such as a low joint) will make the adjacent drive axles move out of level with each other, which is exaggerated at the crankpins since they are past the ends of the axle. Without sufficient clearance in the side rod bushings, it will try to impart a twisting force from one end of the side rod to the other.

All that adds up to more clearance on the side rod bushings than you would see in almost any other plain bearing application. It has to be this way. It is designed to be this way. Yes, the clearance can be reduced by half and the locomotive will still roll out of the shop. But in the real world, that lack of clearance will lead to excessive friction, overheating, and in due time, seizure.

The downside to all this is that when the locomotive is drifting along, all of the extra clearance will run in and out with every revolution... producing some pronounced clanking. When the locomotive is up to speed, the clanking tends to disappear, since centrifugal force has the side rods trying to move to the outside of the wheel, and the crankpins exert a centripetal force that restrains them. The rod bushing never comes out of contact with the crankpin, and thus doesn't clank. Also, under load, the clanking can be minimized since the side rods are transmitting energy to the wheels, which tends to take up slack, and the louder exhaust sound tends to drown it out, too.

So, some clanking is normal for a steam locomotive with plain bearings in the side rods.