I'm building a layout with Atlas O, I've been doing more research than building. I would like some advise on how to bend Atlas O flex track.

Replies sorted oldest to newest

Oman posted:I'm building a layout with Atlas O, I've been doing more research than building. I would like some advise on how to bend Atlas O flex track.

Darned near impossible, in my opinion! During our layout construction, I soldered 3 or 4 sections of Atlas solid nickel "flex track" together. Then it took at least four strong adults to FORCE the long assembly into the required position.

Hot Water posted:Oman posted:I'm building a layout with Atlas O, I've been doing more research than building. I would like some advise on how to bend Atlas O flex track.

Darned near impossible, in my opinion! During our layout construction, I soldered 3 or 4 sections of Atlas solid nickel "flex track" together. Then it took at least four strong adults to FORCE the long assembly into the required position.

We had the same problem trying to bend Atlas flex at AGHR.

I wonder if the problem is friction between the rails and ties. Could spraying the track with a lubricant (WD-40?) before bending help? I'll see if I can grab a section and experiment.

I've also heard of removing the rails, bending them, and re-inserting, which sounds like a gruesome job.![]()

There is ONLY one way to bend Atlas O flex. I have tried every method and only one works. Determine the radius that you need to achieve first. Example:

a) O-72/81/90/99/108

b) Bend and flex over your computer to find the best price for those radii curves purchased as individual curved sections and buy them. Sixteen to a circle.

c) Good luck

d) For those of you who successfully bend Atlas O flex, there is a serious body builder competition here in Carmel and you are bound to win it.

Find one of these rail benders from Norm's Model Supply and reverse engineer it - There was a video somewhere - he was at York in the Atlas booth - it slides back and forth and you gradually tighten the dial - then he left this earth too soon and the railbender was not picked up by anyone. Had a three rail and two rail setup by adding the guide rollers.

Other than that - buy sectional

I have had no problem bending Atlas flex track. I have not tried to make it a specific radius; I have merely said to myself lets make this area a curvy one and fit the track in. It is necessary to have screws ready to secure the bend as you work along. I did this recently and realized I had forgotten how to do it quickly. Therefore I went slow and it was fine. The toughest part is knowing where to cut off the excess and to have the track end section ready to put in place.

I just reread the post wondering why I seem to think it is easy. I am no strong man and getting weaker all the time. The flex track I have had bounces and swings all over the place real easy. It is older ( 10 years ). Has it changed in construction? Each of the rails will slide right out if one wanted to do that. I found it "harder" to keep the in place.

Will follow. Ernie

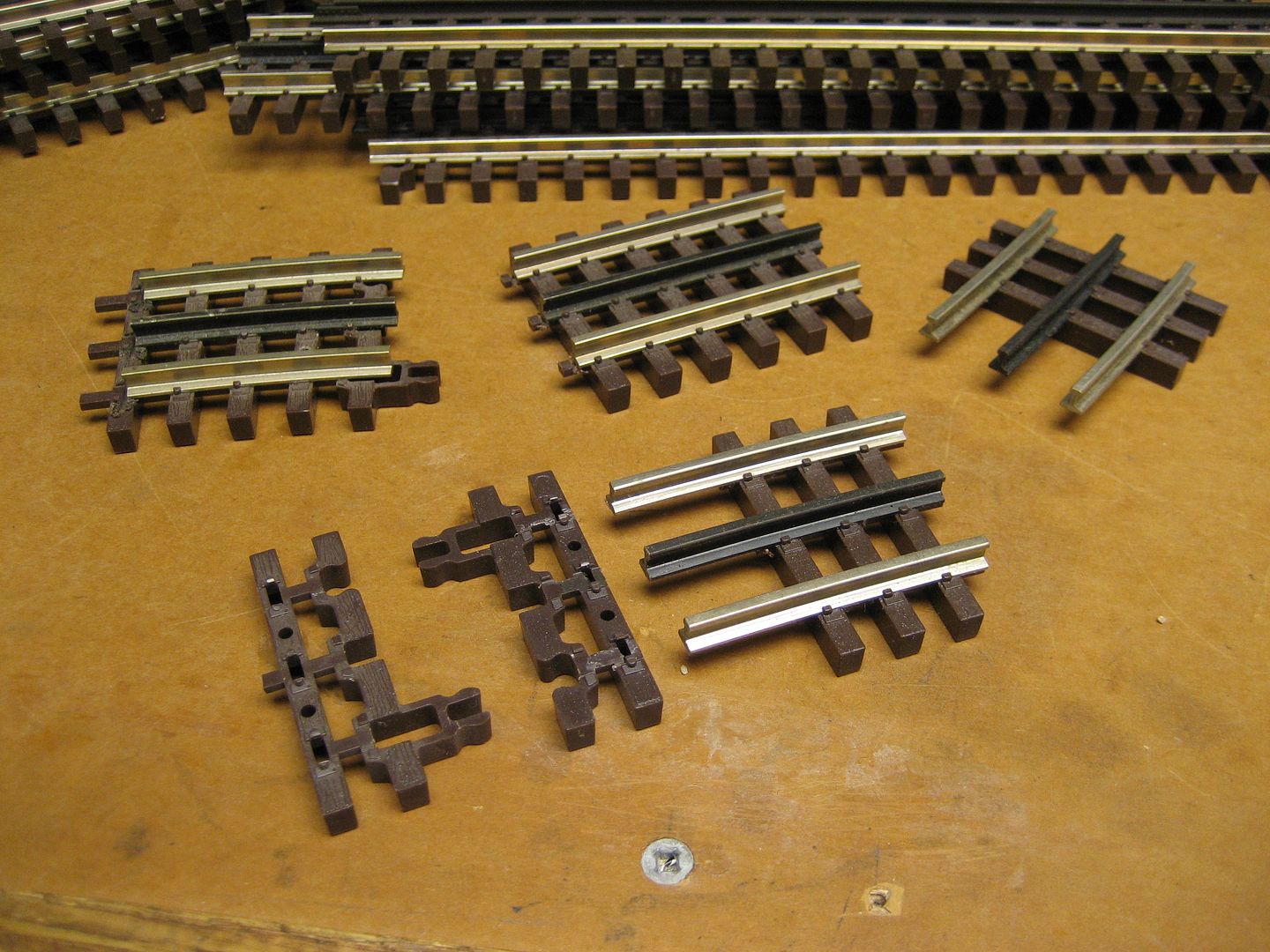

The one area that required a flex track. The curves pictured are O 54. Small switches are O 36.

I would only use it if you genuinely cant use the sectional track, including cutting up sectional curves to fit what you want.

If you have to use it, and there's always some spots where it works best, the trick seems to be to use a long piece of it and screw it down as you go. I would put a screw in it about every 4" so it doesnt spring back on you while you're working from end to end. Remember that the rails are going to slide around, so you'll have so some trimming will be required when you're done.

I too have had very little trouble with the flex track bending issue. But if you plan to go less than 0 72 I would consider trying to use the precurved track. You just have to start and screw the ties two to a tie for about 3 ties from the end, then work your way around from there with one screw in every tie with the holes predrilled as it comes. Use the dremel to lop off the long end at the end of your curve. I have not had any trouble with the track not sliding but you may wish to make sure it slides fairly easily before you start the bending process. It should break free easily if you grip it with a vise grip. Of course no tool kit is complete without a good vise grip. The prechinese kind are still the best if you can find them.

I've reworked this section of my plan many times and just cannot get away from using flex track. My goal has always been to have curves no tighter than O-72. However, the curve between the two O-72 turnouts is O-60. I can live with that, but the Atlas sectional is O-63. I'm going to try removing the rails from the ties and use a rail bender. If it is too difficult re-installing the ties, I may cut the center plastic stringer every 4 ties and re-install the ties in groups of 4. I have a number of other areas in my layout where I intend to use flex, but if the flex is too difficult I can resort to sectional.

Attachments

Bending Atlas Flex track is an unmitigated nightmare! I had a double track S curve that mandated flex and I was determined not to use Gargraves for the better ties.

I had to solder 3 section of track together and I needed 4 hands. After much cussing and clamping and bending and cutting and screwing I vowed NEVER to do it again.

I used the gradual sectional track method as described by Scrap Iron Scher and it was a ton easier.

Some of the odd curves can be created using sectional curve pieces. These pieces can be cut/fit to the needed curve using the same atlas end pieces used for the flex track, cut to fit. Note this S is slightly short of two full piece of O 54, right in this picture.

Atlas track end pieces for custom cuts.

Atlas 6057 end piece(s).

Hey Keith,

I reworked the wye as that looked liked the area of concern. The photo was too blurry to specifically identify the switches and curves 100%. I used Ross switches and Atlas track.

I was able to reduce the need for flex to the two straighter areas. The rest is full or cut sectional pieces.

The diagram and the SCARM file is attached. if you have SCARM, when you open the file, grab the gray triangle at the low right corner of your image and left-click and drag to overlay it on the design that I made. The shape is very close. I think this will fit in your space.

I have also created a document about bending Atlas Flex track. I searched many old forum posts. I believe that the last two paragraphs are the key to making it easy enough for you to create the large radius fitters that you need. Document attached.

I hope it helps.

Attachments

When installing 3r Atlas flex track I stagger each individual rail 12". Simply slide 0ne rail 12 " into the next section and the third rail 24" into the next section and bend it into shape. Once you have the rail end location established take a rotary tool and scoop out the tie plate area of the tie for the joiner. I do not trim cut/line up Atlas flex track rail ends until the curve forms into tangent.

I have not used Atlas flex for small radius curves.

Also, a few years ago there was forumite who has a machine shop in Ohio I believe, who makes a motor driven flex track bender suitable for Atlas flex track. I believe he priced it at $200.

Three rail Atlas flex is not fun in any installation except very wide curves or cosmetic (800" to 1200") curves. For cosmetic curves Atlas flex is best, IMO.

Thanks Moonman

Because the ends of the Y need to line up with track (not shown) on different levels, I wasn't able to use your rendition. However, you did give me an inspiration that resulted in a much improved Y. By replacing the half O-72 at the top of the Y with a 1/3 O-81, I was able to configure the previous O-60 flex with O-81 sectional track. Now, the only flex is a broad 150" radius at the bottom of the layout.

Attachments

Oman posted:Thanks Moonman

Because the ends of the Y need to line up with track (not shown) on different levels, I wasn't able to use your rendition. However, you did give me an inspiration that resulted in a much improved Y. By replacing the half O-72 at the top of the Y with a 1/3 O-81, I was able to configure the previous O-60 flex with O-81 sectional track. Now, the only flex is a broad 150" radius at the bottom of the layout.

I think the tips provided by the gentlemen should make it reasonable to pin the end and bend as you go on the flex track. No one has come close to Norm's rail bender for the Atlas. Code 215 is some tough stuff.

Remove the rails from the ties. Run them trough a rail bender to get proper diameter for each rail. Reinsert bent rails in ties.

Did all my curves (over 99" diameter this way.) Tedious but no screws required. Rail bender tends to slightly twist rails. So track tends to have a slight-- but not objectionable to me -- twist. Does not effect operation.

Has anyone actually asked Atlas reps what in their experience works best?

c.sam posted:Has anyone actually asked Atlas reps what in their experience works best?

Your kidding,,,,,,,right?

Why the problem making "esse" curve?

c.sam posted:Has anyone actually asked Atlas reps what in their experience works best?

I did, and he said don't use flex track. However, he was referring to typical curves like O-72. For larger curves beyond O-108 (that is O-117) , they probably work fine.

Moonman posted:Oman posted:Thanks Moonman

Because the ends of the Y need to line up with track (not shown) on different levels, I wasn't able to use your rendition. However, you did give me an inspiration that resulted in a much improved Y. By replacing the half O-72 at the top of the Y with a 1/3 O-81, I was able to configure the previous O-60 flex with O-81 sectional track. Now, the only flex is a broad 150" radius at the bottom of the layout.

I think the tips provided by the gentlemen should make it reasonable to pin the end and bend as you go on the flex track. No one has come close to Norm's rail bender for the Atlas. Code 215 is some tough stuff.

Yup

That's what I thought; bend and screw until it's in place.