Does anyone have pictures of bridge shoe placement, and how you attach them to the bridge.

Replies sorted oldest to newest

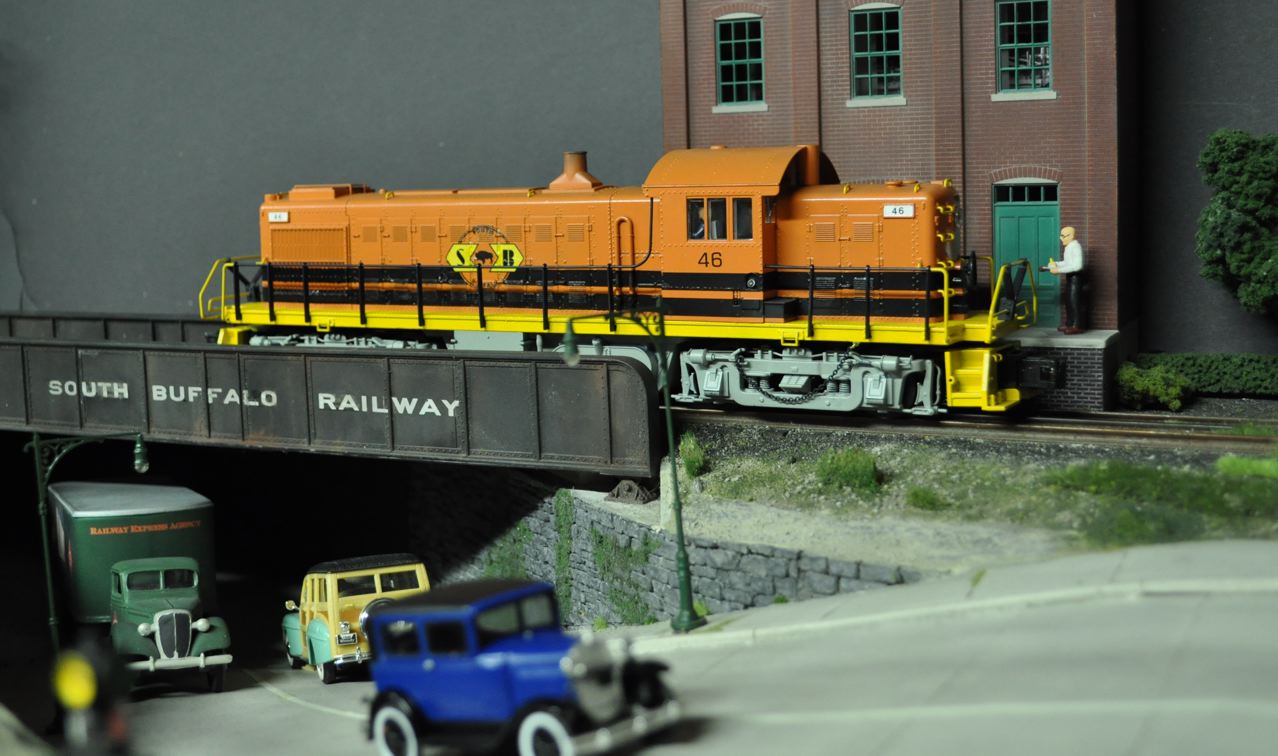

Rob, Here are two pictures of my Atlas O bridges. Hopefully these will help.

John Rowlen

Attachments

None of my six Atlas O Pratt Truss bridges had shoes with the bridge, lifts that go under the ends. The gray plastic is a cement end cap for the bridge, not a shoe to elevate the bridge. You will need to build your own shoe or support pier for under the bridge.

Sincerely, John Rowlen

Rob, Scenic Express carries the bridge shoes ( sets of two in a package ) that work with Atlas bridges plus the bridge abutements as well.....Paul

Bridge shoes go under the beams near the end. I think these are Keil line but not sure. I made this 15 years ago.

Few brains cells still working. You can find them here:

http://scalecitydesigns.com/sc...line/bridge-details/

Posted by another forum member:

Pete

Thanks for the info. I have the Atlas Pratt Trust bridge, and under the ends of the trusses are hollow. My question is should the shoes go under the beams directly under the tracks, or do I have to create something to fill the hollow trust.

The shoes should go under the main structure of the bridge, as Pete is showing, not under the track.

i see the placement, but on the Atlas model there is on bottom plate where the shoe goes. Should I install a plate, or move the shoe back away from the void

Rob, I get what you are saying about the void; but, how about a photo to show us what you are dealing with.

Obviously, whatever you put there must be itself, and to whatever it is attached, structurally sufficient for the load to be borne.

Pictures below show my scratch-built truss bridge, shoes and piers. On my layout, the shoes rest on U-shaped "steel" pads which rest atop the abutments without being secured. The underside corners of the lower main truss beams have a thin (1/32") plate with a recess into which the tops of the shoes fit. The bridge is just placed onto the tops of the shoes. The "steel" pads can be moved as necessary so the bridge rests squarely atop the shoes. The weight of the track (and trains) is sufficient to prevent the bridge from moving. Shims of thin wood or paper can be placed beneath the shoes so that the bridge is supported equally on each corner. If the layout has to be transported, the bridge can be lifted off the layout just by removing the track - which is a single 40-inch rigid Atlas O straight.

MELGAR

Attachments

Rob,

Here are a couple of shoots of my Atlas Pratt with bridge shoes. The shoes I have were just about as wide as the void in the bottom of the truss so I just glued them in place. A thin sheet of styrene could be glued into place over the void and then the shoes attached to it.

Al

Attachments

FrankM,

I debated for a while before deciding to answer your question. Your modeling and scenery are so extraordinary, realistic and artistic as to make the mounting of the bridge irrelevant to anyone except a structural engineer. The full-sized bridge design is such that it would be supported only by bridge shoes and only at the four corners. The shoes allow for expansion and contraction due to changes in temperature and prevent certain types of forces (and moments) from being imposed on the bridge's structural members. The relevant point here, which definitely applies to me, is that "Imagination is more important than knowledge. Knowledge has limits." I hope you're getting along OK.

MELGAR

MELGAR, THANK YOU for so informative a reply about bridge shoes. Your succinct explanation was a nice lesson to learn.

And more importantly, your very, very kind viewpoint of my layout work has given me the first big smile I have had in a couple weeks, now.

Thank you, also, for your thoughtfulness in asking about how I am getting along. Little by little, bit by bit. I am learning in this regard, too. The silence in the house, now, is so loud.

You are a gracious gentleman.

Thank you, again.

FrankM

Here is a link to the Bridgehunter page for the prototype of this bridge.

https://bridgehunter.com/mo/butler/mengo/

Great pics, including one of the actual shoes used by these spans (there are two of them plus a plate girder).

BTW, it's worth noting that, despite the Atlas nomenclature, it is a Warren Truss, not a Pratt.

Moonson posted:

MELGAR, THANK YOU for so informative a reply about bridge shoes. Your succinct explanation was a nice lesson to learn.

And more importantly, your very, very kind viewpoint of my layout work has given me the first big smile I have had in a couple weeks, now.

Thank you, also, for your thoughtfulness in asking about how I am getting along. Little by little, bit by bit. I am learning in this regard, too. The silence in the house, now, is so loud.

You are a gracious gentleman.

Thank you, again.

FrankM

The coefficient of thermal expansion for carbon steels is about six-millionths of an inch per linear inch per degree F. Now some alloy steel gauge blocks I have used only had about three-millionths ratio.

Ron

Moonson posted:MELGAR, THANK YOU for so informative a reply about bridge shoes. Your succinct explanation was a nice lesson to learn.

And more importantly, your very, very kind viewpoint of my layout work has given me the first big smile I have had in a couple weeks, now.

Thank you, also, for your thoughtfulness in asking about how I am getting along. Little by little, bit by bit. I am learning in this regard, too. The silence in the house, now, is so loud.

You are a gracious gentleman.

Thank you, again.

FrankM

FrankM,

The most important thing to me is that my comment gave you a little something to smile about.

MELGAR

PRRronbh posted:The coefficient of thermal expansion for carbon steels is about six-millionths of an inch per linear inch per degree F. Now some alloy steel gauge blocks I have used only had about three-millionths ratio.

Ron

I'm not quite sure of the purpose of your comment but if you are seeking engineering justification, I'll give you some numbers.

Length of bridge = 225 feet = 2700 inches

Temperature range (0 deg-F to 120 deg-F) = 120 deg-F

Expansion = (6E-6 inch/inch/deg-F) * 2700 inches * 120 deg-F = 1.944 inches

Strain = Expansion/Length = 1.944 inches / 2700 inches = 0.00072

Young's Modulus (carbon steel) = 29,000,000 psi

Stress = Young's Modulus * Strain = (29E6 psi) * 0.00072 = 20,880 psi

So, if the lower truss member of this example is mounted at 60 deg-F with no provision for expansion/contraction, the compressive stress at 120 deg-F would be 10,440 pounds-per-square-inch and the tensile stress at 0 deg-F would be 10,440 psi. Yield stress would be about 50,000 psi.

The other point is that bridge shoes of the type in our models allow the structure to rotate freely about the pin in the shoe, which produces zero bending-moment to be transmitted into the structure through the shoe.

MELGAR

Thank you for all the replies. I will be attaching a plate over the void to attach the shoes. I also like the idea of putting rails under the shoe like the real bridge used in the photo from Palallin. Thank you everyone again.

I had to glue a pad across the ends to accommodate the bridge shoes. These are Scenic Express in the photo.

Scale city has some nice ones too: