What tool do you use to cut sections of Gargraves track? What method have you found to be the best for making fast, clean, crimp free, spur free cuts that allow for easily reinserting track pins into those cut ends?

Replies sorted oldest to newest

ogaugeguy posted:What tool do you use to cut sections of Gargraves track? What method have you found to be the best for making fast, clean, crimp free, spur free cuts that allow for easily reinserting track pins into those cut ends?

The best method, for positively accurate square cuts, would be the inexpensive "chop saw" (cut-off saw) from Harbor Freight.

I use a dremel drill with a larger cutting wheel to get a straighter cut...........Paul

Dremel with Gyros cutoff wheels http://www.gyrostools.com/ much more robust than Dremel brand cutoff wheels. Follow up with a needle file to remove burrs.

Dremel with cutting wheels, fast with excellent accuracy.

Bill T.

Like the guys said....you will also have to have a small nail on hand to open up the cuts for your track pins. Just tap it in, open rail, insert pin.

Jerry

I use the large Dremel Premium Metal EZ wheels. I mark with a Sharpie and then cut each rail. I then use a Dremel grinding stone to take the sharp edges off the rails.

George

Dremel Sawmax

Chop saw, angle grinder, die grinder, Dremel. Always using a reenforced disc.

Maybe a good band saw.

As stated above many times, the Dremel tool with a metal cutting wheel is the ideal way to cut your track. If you are using a standard Dremel metal cutting wheel, the body of the Dremel will come in contact with the track before the wheel cuts through the track preventing you from getting a vertical cut. To prevent this I use the extension cable when cutting track.

However, when using the Dremel tool be sure to wear safety glasses as the cutting wheel can sometimes throw up very small bits of metal.

Jim

Dremel with a large 2" diameter fiber reinforced cut off wheel and a wooden jig I made for straight cuts.

I usually use painter's tape and put down a few pieces at the cut line on the side of track I want to keep in case the cutting wheel slips or I sneeze or something. I clamp the jig and the track to the edge of the table for stability.

I used to have a flexible shaft dremel that would give me a very nice perpendicular cut to the rail. But that old boy died, now I just use the regular machine, I think a 4000 or something like that. I make the cut a little long (2mm) and square it up with the front face of the wheel using it as a grinder.

Have been doing it this way for 30 years and never had an issue.

OH....and do not forget EYE PROTECTION. I wear glasses most of the time so I cover them with goggles.

Donald

Dremel tool with a cut off wheel. Size varies depending on the job. Works great both on and off the layout for cutting track, making isolated sections, etc.

Dremel with a right angle attachment and gyros ST wheels.

Hot Water posted:ogaugeguy posted:What tool do you use to cut sections of Gargraves track?

The best method, for positively accurate square cuts, would be the inexpensive "chop saw" (cut-off saw) from Harbor Freight.

I also recommend this saw. Low cost and accurate. Unfortunately I destroyed mine trying to cut some metal train shelves, so no bigger jobs with this.

You can get fiber glass reinforced discs for a dremel in many hardware stores and hobby shops. I find them locally quite easily.

A very fine toothed hand saw such as the Atlas Hobby saw also works.

In both cases you have to hold the track firmly - with a clamp if possible.

I did a layout with gargraves many years ago.

Shorling has it right. Dremel with a cut off wheel. It can'r be any easier.

eddie g posted:Shorling has it right. Dremel with a cut off wheel. It can'r be any easier.

Unless one is unable to hold the Dremel perfectly square with the rails. That is why the Harbor Freight "Chop Saw" (cut-off saw) works so well, plus it cuts all three rails square at once!

I used a dremel at first and didn't like having to clean up the burs, I switched to my portaband and will never go back

I have no experience with a chop saw; but, have plenty of experience with a Dremel, with and without the flex-shaft; and, with and without the 90 degree attachment using a variety of cut-off wheels.

For those who use a chop saw, how do you cut the uneven ends created by curving the track?

Pingman posted:I have no experience with a chop saw; but, have plenty of experience with a Dremel, with and without the flex-shaft; and, with and without the 90 degree attachment using a variety of cut-off wheels.

For those who use a chop saw, how do you cut the uneven ends created by curving the track?

I cut the uneven ends off square, and then attached the next piece of track. For the big curves when using Atlas flex-track, I soldered 3, 4, or 5 lengths together, then with 4 guys, we bent it int place. We then cut the staggered ends off square.

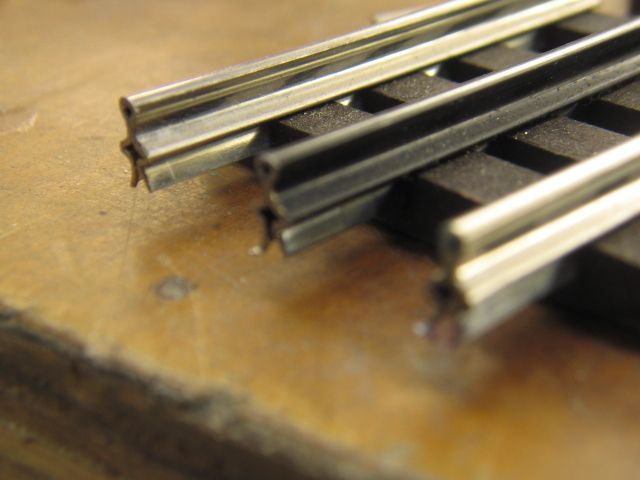

Attachments

paul 2 posted:I use a dremel drill with a larger cutting wheel to get a straighter cut...........Paul

Same here.......I wore one out building my layout but works GREAT!!

I do it rather differently. I make a rough cut with a pair of tin snips, then use a table top, 1" belt sander to grind off the crushed material. Been doing it this way for 26 years. Works for me.

No cut off wheels. You never get a straight cut with them anyway.

I use a 4 1/2" right angle grinder with thin cut off wheel first then for final fit the Dremel with the good cut off wheels.

Attachments

Dremel, flex shaft, 2" cut-off wheel and eye protection..

The dremel right angle tool may make cutting track easier. I use a bench grinder to finish the cut.

Better look at the right angle tool.

Bench grinder used to true cut ends.

Boilermaker1 posted:Dremel with a right angle attachment and gyros ST wheels.

Me too.

The photo is from HF's website for their lowest priced cut-off saw. Is this the model folks refer to? If so, how does it cut the uneven ends on bent flex track, e.g. Gargraves? I ask because it appears the track must be lifted and placed on the saw. How can GG track be lifted in place without the rails shifting? Is the curved track removed from the layout and then trimmed?

I use a small bench band saw with a metal cutting blade then deburr with a 1" belt sander and an awl.

ogaugeguy posted:What tool do you use to cut sections of Gargraves track? What method have you found to be the best for making fast, clean, crimp free, spur free cuts that allow for easily reinserting track pins into those cut ends?

Best method? I have a few friends come over and do it while I kick back with a beer and watch some railroad DVDs. ![]()

Just kidding. I've actually used a small hacksaw with fine teeth, and a file for light cleanup. You have to be careful when using a hacksaw though, so you don't accidentally bend the rail while if the blade snags in the cut while sawing. Clamping the rails in some manner helps considerably while sawing.

I use a Dremel with a fibreglass or EZ lock cutting wheel. The latter seems to last longer. Rather than monkey with the right-angle tool, I cut on the end of my workbench whenever possible. I use goggles because bits to fly,

I Gauge Him posted

As stated above many times, the Dremel tool with a metal cutting wheel is the ideal way to cut your track. If you are using a standard Dremel metal cutting wheel, the body of the Dremel will come in contact with the track before the wheel cuts through the track preventing you from getting a vertical cut. To prevent this I use the extension cable when cutting track.

I'm interested in what is an extension cable Jim? Where do I purchase the extension cable Jim?

I work with Gargrave track...

Thanks

John d.

John d Sewell posted:Where do I purchase the extension cable...?

Extension Shafts HERE.

I use a Dremel often. The easy way is to make the first cut about a quarter inch longer than you need. Then you can make the final cut vertical without the body coming in contact with the track.

2 cents

Dremel 2 inch cut off wheel. Works perfectly just go slow and easy.

I use this from Harbor Freight

Attachments

Chop/Mitre saw. Straight smooth almost perfect cuts. If you don't have one - you can get a pretty nice one at Harbor Freight for about $80 - $100.