Hello David,

In your original posting you didn't state from which direction the derailments are happening. Are they much more prevalent in one direction vs. another. If so then look at the points as others have stated.

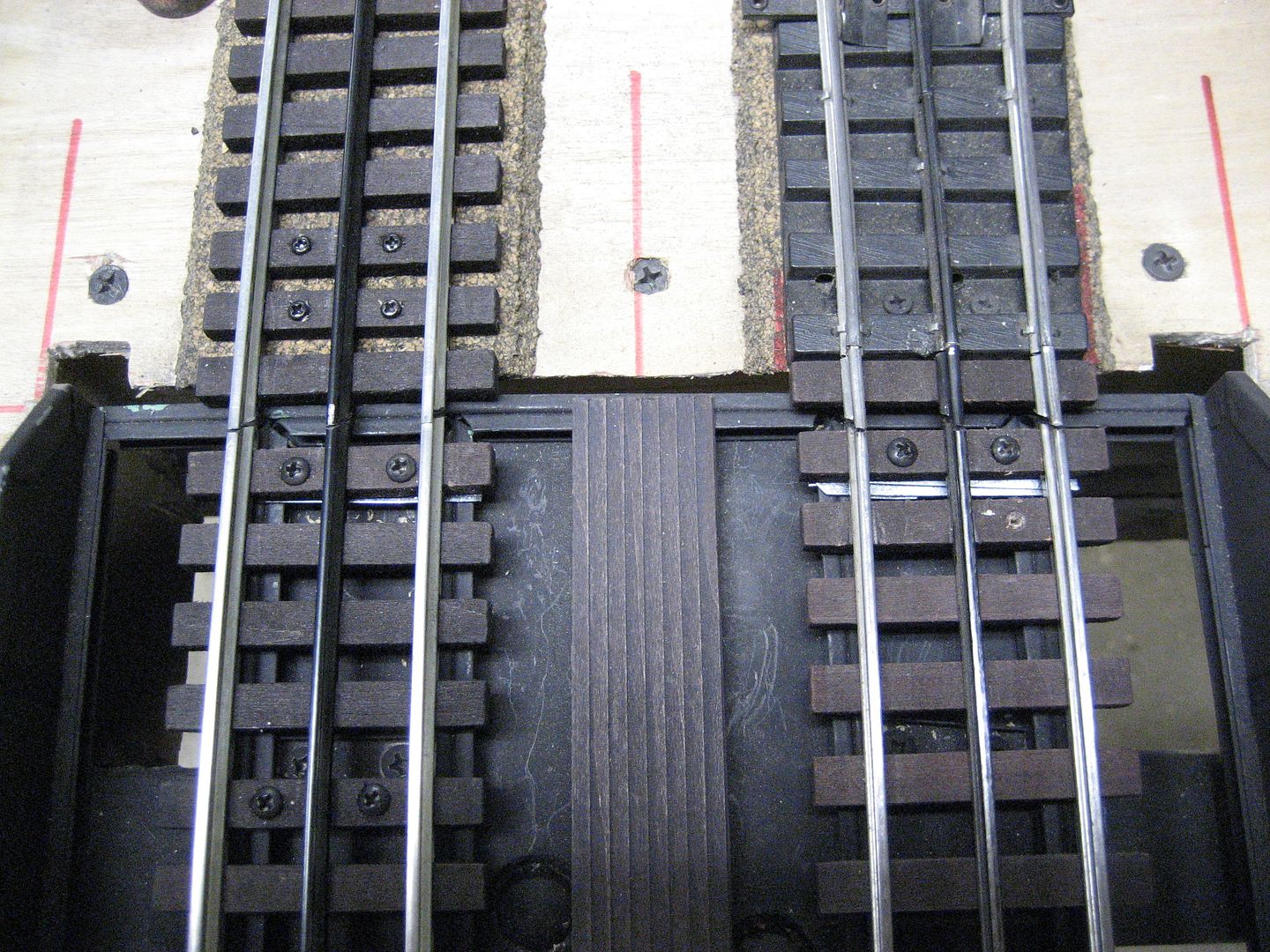

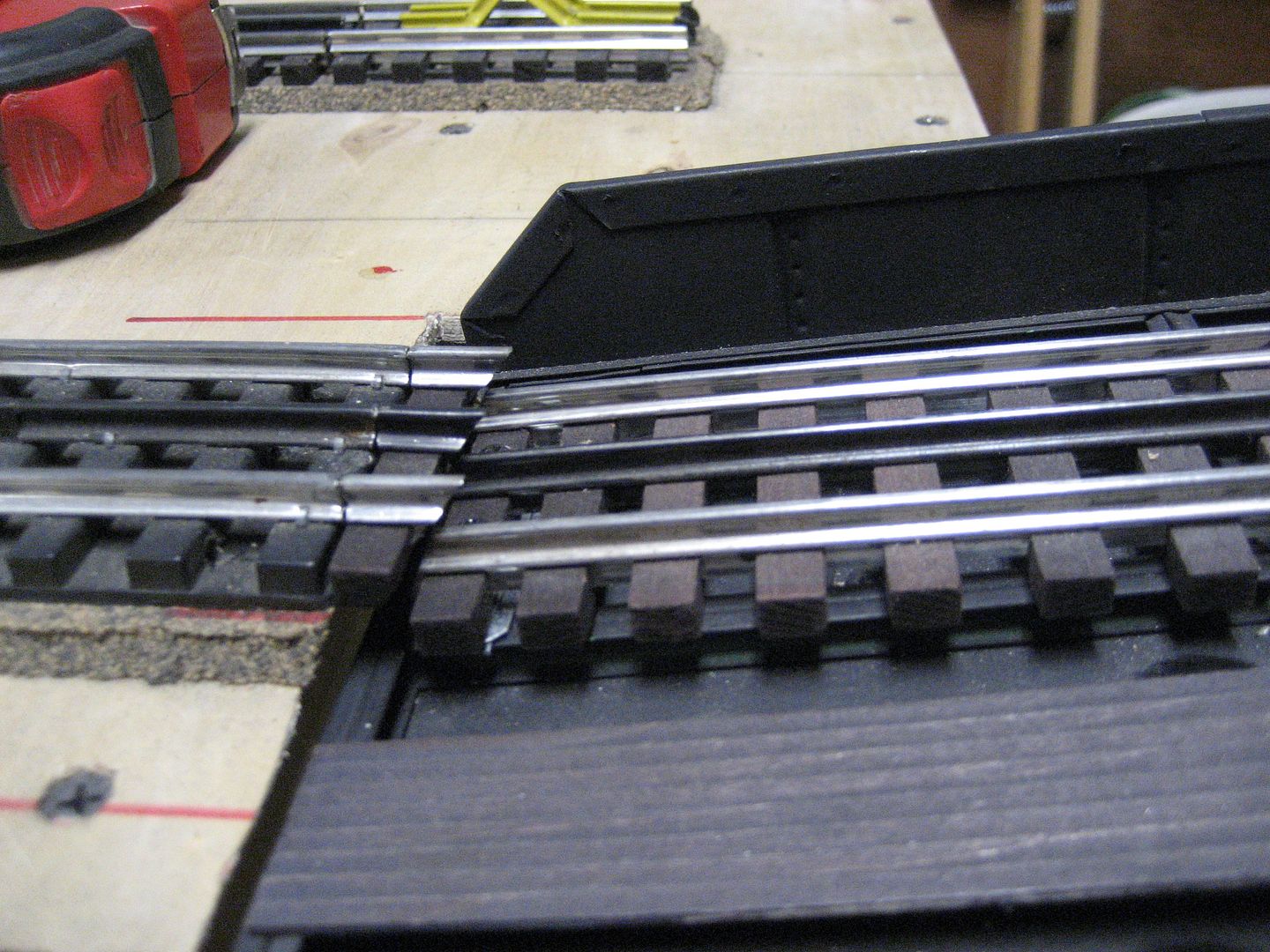

The outside rail looks like an issue to me especially if the train is coming from the top of the picture to the bottom.

As others have stated, reduce the size and height of the screws being used as it looks like they are sitting much to high and could be snagging a wheel set when it comes through.

Take one of the engines that derails and very slowly freewheel it across the bridge. While doing so carefully examine how the wheels (especially the front trucks) are moving. If you feel any resistance even for a moment. Back up the engine and try that spot again. Should it happen again, look to see what is going on as this may be your issue.

You need to do some detective work in order to figure it out. Also note what happens to the bridge height as the Locomotive crosses onto the bridge. Does it sag or shift. If so shore up the bridge so that it cannot move.

These are my initial thoughts just looking at two good photos out of three. A short vid would help as well in the diagnosis for us who are trying to assist from a distance.