I purchased this kit from a forum member as a winter project and I have debated on putting up a post on it's construction. This is one of the older Korber kits. The instructions are minimal at best and the walls were warped. Baking them at 250* fixed that issue.

I'm starting this post well into the build of this roundhouse. I am now at the point of getting ready to attach the wooden structure to the wood base. I have a few more things I want to do before permanently attaching it. I have watched a couple of Youtube videos on guys building the Korber #304 Roundhouse and an Altoona roundhouse. I have incorporated some features from both of those roundhouses into mine. The picture of my 4449 Daylight sitting in the door just barely fits into the house and missed the structure. This is due to the fact that the structure is not sitting on the round house floor yet. I have done some measuring on my tallest engine and have determined there will be plenty of room.

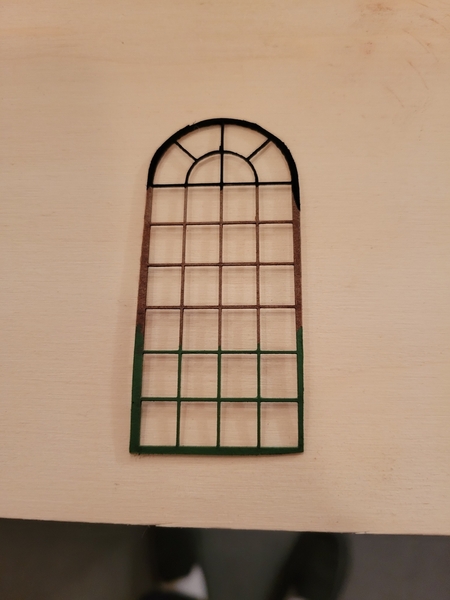

This is the point I was at yesterday morning, just prior to painting the wooden structure white. There will be a black bases of about 3/4" on the bottom of the columns. I decided to go with matte Kelly Green skylights and doors.

On the subjet of the doors, these will be able to open and close. I'm starting with this option and I'll see how well that'll work. If not, They'll get glued open later.

The front facade is all glued together. This will be attched at a later date when the structure and the rest of the resin pieces are in place. This is due to the fact that the doors will be attached and I don't want to bust them off, just from the way they're designed.

Just a quarting view.

As you can tell, there is lots of added beams added to the framing. This is one of the things I took away from the Altoona Roundhouse kit.

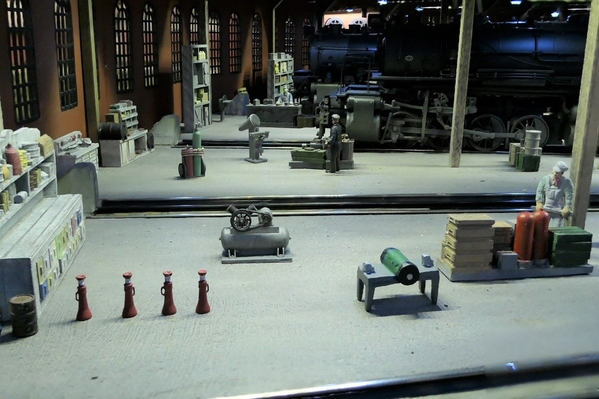

The lamp shades are from Scale City Designs. The brass tubing is 3/64" from K&S. The LEDs are PLCC2 3528s. I'm hoping this will be enough light to illuminate the inside. All of the wires are 30 gauge enameled magnet wire. All of the LEDs were ops checked prior to gluing them in place. The magnet wire is glued to the bottom of the beams to be hidden and will go under the table to a distribuation block. There is a total of 18 lamps. The inside of the lamp shades are painted white and the LEDs are painted white on the back side to help insulated them from shorting out on the lamp shades.

The doors just hanging on the front facade.

I got kinda lucky and placed the lamps in between the windows. This was completely unexpected, but it worked out very nice.

All the roof panels roughly in place to get an overall effect. The photo of my Daylight sitting in the barn. Just barely fits without the flooring.

This is where I am as of last night. The structure has been painted white. I will paint the bases of all of the columns black, the lighting pipes will be aluminium and the lamp shades will be a green. I will then place the structure permanently to it's base, add the track, and then add the flooring to the tops of the rails. I am not too worried about a turntable as of yet. The tracks will end about 2"-3" in front of the roundhouse and then be extended to the turntable when I can afford one, but no Bower. I saw the recent posts.

I welcome any suggestions or comments. Thanks for looking.