I know the new remakes have the added function of remote-control traverse movement but has anyone done it with a PW Crane? String/fishing-line with pulleys under the deck and a crank at the front is all I've come up with?

Lew

|

|

I know the new remakes have the added function of remote-control traverse movement but has anyone done it with a PW Crane? String/fishing-line with pulleys under the deck and a crank at the front is all I've come up with?

Lew

Replies sorted oldest to newest

geysergazer posted:I know the new remakes have the added function of remote-control traverse movement but has anyone done it with a PW Crane? String/fishing-line with pulleys under the deck and a crank at the front is all I've come up with?

Lew

I've seen a pic of one with a nut, some how, attached to the lower frame and a threaded rod running through the nut.

The threaded rod is attached to a motor. I don't know how well it worked. Like I said, I just saw a picture of it.

Steve

Some of us have used common hardware store threaded rod as a leadscrew. Also Train America Studios back in the day used plastic chain and sprockets located on top of the layout. The ends covered by small buildings.

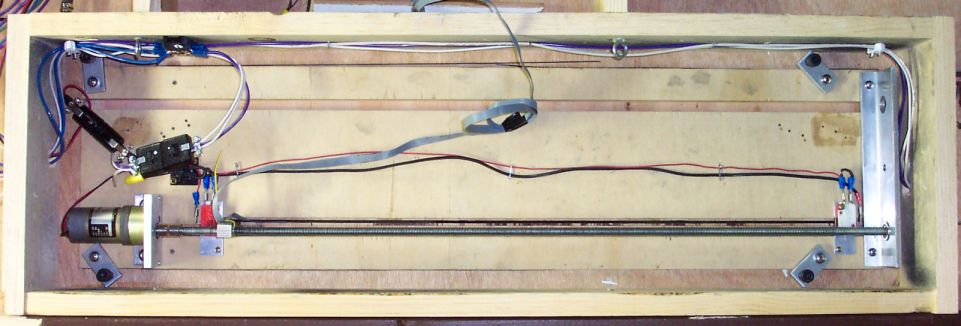

The lead screw can be mounted on top or below the layout driven by a DC gear motor. I mounted my mechanism under the layout with the nut connected to one leg of the crane by a small piece of spring tempered metal.

Pete

Nice Crane, Pete. Thanks.

I'm thinking about the guts of a Gantry Crane below the deck with the winch drum above the deck. Maybe a pulley with a weight suspended under the deck for return force. Kind of expensive and a waste of a Crane base and mechanics though.

On edit: It took awhile for the pics to post. Nice work on the screw drive.

Lew

Lew- I have been contemplating a similar project. I scavenged some motors and drives from a dead ink-jet printer recently. Now I just need a crane, space on my layout, time, time, more time......![]()

The motors are all DC. The one in the video is running on an old HO transformer.

There are several threads here on the forum if you dig through the search a little.

Oops. I so easily forget that I can "search". Tnx!

Lew

TAS (Train America Studios) created a kit many years ago that does this. I still even have a unused kit. Quick google search didn't find pictures of it in action.

Jim

I think David from Dearborn had built one surface mounted using a tether and posted it.

If you do motorize, flipping polarity of a can motor would be easiest and more controllable overall. With a gravity return, one slip in alignment means back to square one to start over.

Check out the attached for a very simple method to get gantry crane traversing movement.

I have an extra New in box TAS kit I am willing to sell.

Jcooper1973@comcast.net

When I get home Sunday I can see what It cost and determine how much to discount, if anyone is interested.

I added traverse movement to my PW crane some years ago. I beleive that there's a thread on it somewhere. Along with that, I also mounted relays near the crane so that I cane use 22-ga wire between homebuilt control box and crane. I used threaded rod. If you do, be sure to use microswitches to limit travel. Pix & schematics attached

I should add to the above: The small board in the one corner is a AC/DC buck converter to provide proper voltage for the relay coils. Also one in the controller. Since one characteristic of the PE crane was that it would rotate slightly after relasing an up-down button, there is a capacitor to keep the solenoid relay from disengaging until the motor has stopped.

And the source of the small DC motor/worm-drive unit?

Tnx,

Lew

geysergazer posted:And the source of the small DC motor/worm-drive unit?

Tnx,

Lew

Ebay. Search on DC gearmotor. There are 24,000 hits.

Pete

The particular motor I got was from Radio-Shack on line, while they were still in business.

You do not want one that is too slow, if you are using a threaded rod as I did. If you do use a threaded rod, it must go through nuts attached to two legs, to keep the crane from skewing. Without microswitches, the machine will jam.

Yup, I noticed that you use a nut attached to two legs. Tnx.

Lew

The math for RPM needed lies in the tread pitch you use.

Threads per inch vs rpm is a good way to estimate. I've done that for timing a long worm-drive decades ago. I don't have the formula handy; but it's not too hard to figure yourself. Maybe it was into rev.s per second and back to minutes, I forget. Easy enough I dismissed it as re-learnable stuff I might not need again ![]() .

.

The problem isn't calculating the rpm needed, so much as finding a reasonably priced motor with approximately the desired rpm.

There are no problems, only solutions.

200-300 RPM gearmotors are all over eBay for 5-20 bucks.

If you use 1/4-20 rod you do 20 turns to move 1 inch. 300 RPM means 15" in one minute. A reasonable speed. If you use a 12 v DC motor you can also use a pot in series to further adjust the speed. I have one on mine so I can slow down as I approach the ideal drop point. Likewise if you use a 16v supply you can move faster than 300 rpm.

If you use 5/16-18 rod it will move faster with the same motor. How long your track is will determine how heavy a rod you use. Hardware store threaded rod is mild steel and can bend easily. Any bend will rock your crane side to side. 1/4" might be OK if your track is only a foot long. 18" you might want to consider 5/16"

No doubt you can find precision ground threaded rod but cost will increase.

Pete

Just to throw another set of variables into the mix; Would'nt a smaller dia. rod give a bit more useful gear ratio for maxing a motors torque ability ?

The finer thread pushing harder at the other end of the final drive ratio too?

It would but these are gearmotors. The torque is already muliplied by over a factor of 10 limited only by the strength of the gears used. Sufficient torque is not an issue.

Pete

Yea.. I was thinking along the lines of a direct drive.

In particular off an ho motor, a nice souce of driveshafts, and those skinny, 5-7 pole high torque, sm.dia. dual flywheels, horizontal motors to stay low profile on the cover.

I think one could handle it.

See my post at the top of the thread. That motor is smaller than a Pittman. It takes very little effort to move the crane. A smoke fan motor with 100:1 gear reduction could do it.

Pete

Try it and report back. Assuming it has the torque it will move the crane faster than a top fuel dragster. More like the speed of sound.

Pete

I'm thinking of both moving at scale speeds and traversing a bit more than than a foot a minute both. Alternates, not contridictions.

I haven't been past the corner since Jan., don't wait on me ![]()

Access to this requires an OGR Forum Supporting Membership