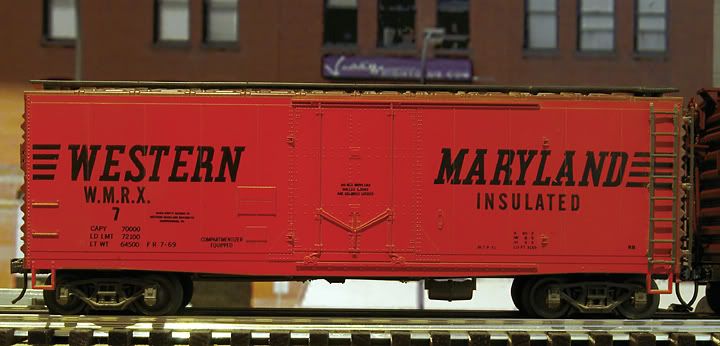

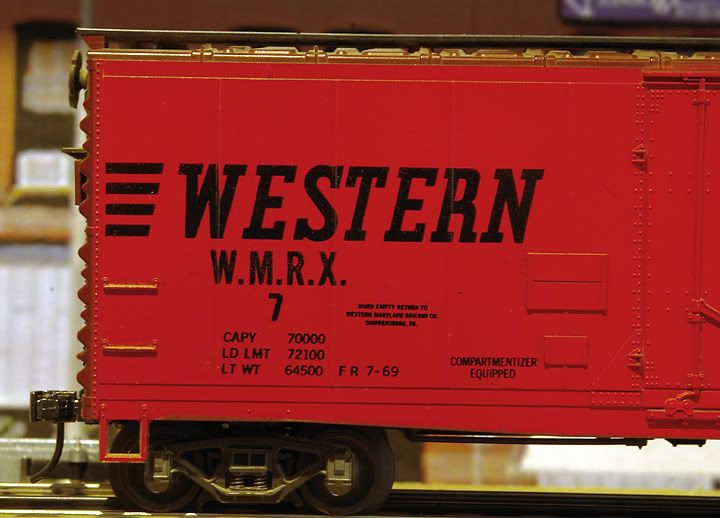

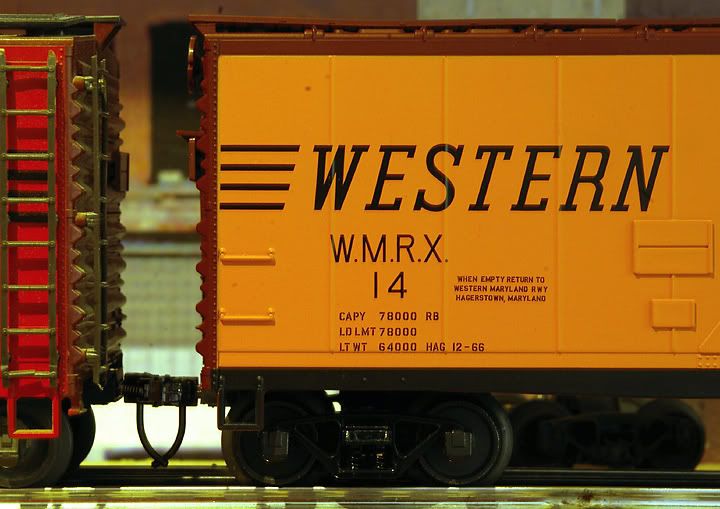

BTW with the truck mounted dummy couplers the old Atlas cars could do pretty much any curve, I remember in the early seventies watching 50' gondola cars zipping around my O-27 curves with no problem!

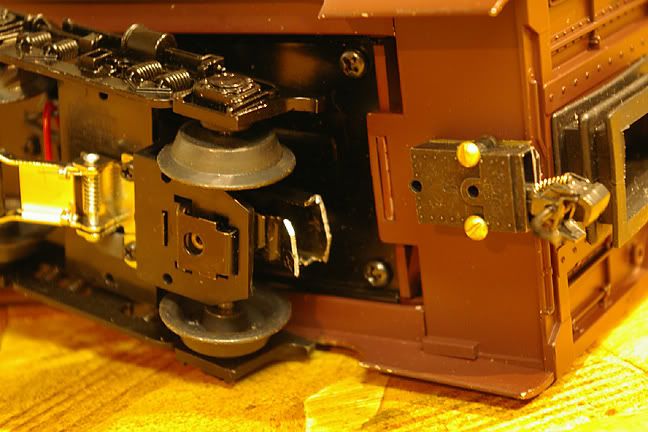

Back in 1983 I got to talk to a Kadee rep at a national train show, and asked him about the O scale couplers. At the time I had quite a few of the "old" Atlas O cars from that time, and wondered about converting them to Kadees on a three rail layout. If you remember back in the seventies-eighties Atlas made O snap-track (2 rail) with a 24" radius curve. He said they used the Atlas track and cars to test their O couplers out on, so it should be good down to O-48.

BTW with the truck mounted dummy couplers the old Atlas cars could do pretty much any curve, I remember in the early seventies watching 50' gondola cars zipping around my O-27 curves with no problem!

BTW with the truck mounted dummy couplers the old Atlas cars could do pretty much any curve, I remember in the early seventies watching 50' gondola cars zipping around my O-27 curves with no problem!